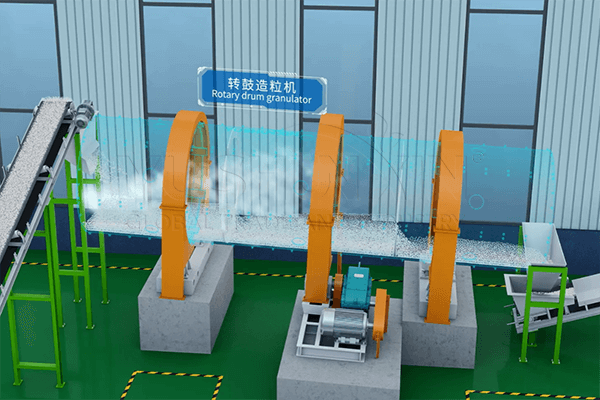

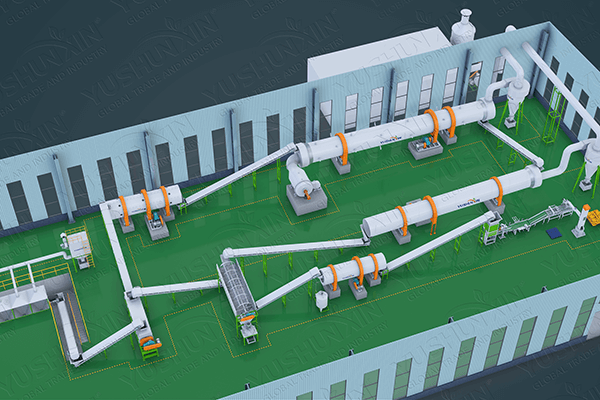

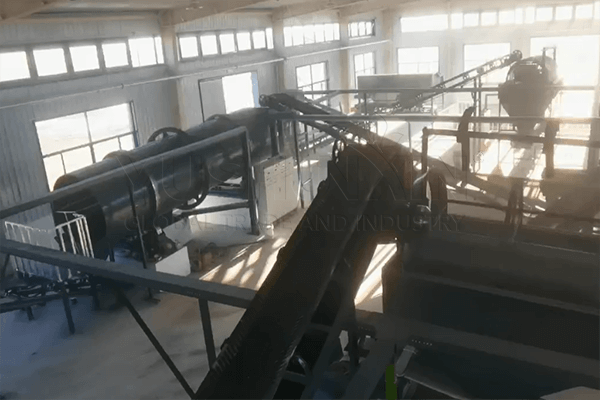

If you want to start a large scale production of fertilizer in a 10-30 TPH capacity faster, steam granulation with drum granulator is an ideal choice. Eapecially, the compound fertilizer granule making with nitrogen fertilizer, ammonium chloride, or ammonium sulfate, etc. Then, for the steam injection, there are professional steam boiler for precisely control. Come to get your customized fertilizer making solution now!

Why steam granulation is beneficial for quickly fertilizer pellet making?

While raising the moisture of fertilizer materials, it also increase the temperature in the rotating cylinder. Therefore, the powdered fertilizer is softer and easier to agglomerate, which make materials form into rounder and stronger fertilizer granules.

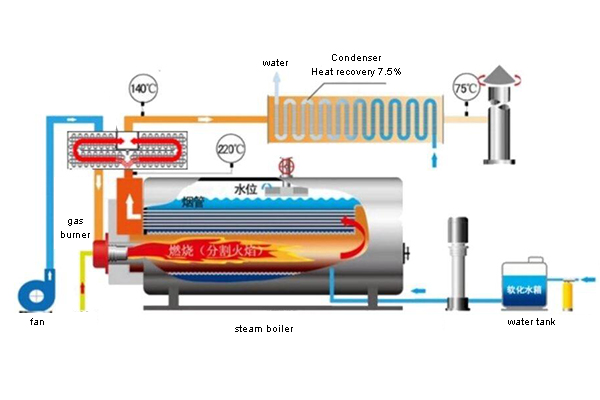

What equipment is commonly used in the fertilizer steam granulation?

For the stream injection to the rotary drum granulator, the machine you need to buy is steam boiler. It will help you precisly add the steam for the hot granulation of fertilizer powder. For the rotary drum granulation machine, it is advisable to add 50-80kg of steam for 1 tons of fertilizer pellet granules making.

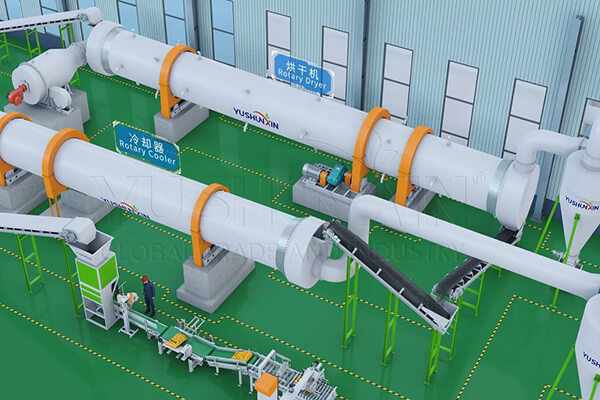

Tip: For the fertilizer steam granulation in rotary drum fertilizer granulator machine, it is advisable to equip a dryer and cooler after granulation to reduce temperature, moisture and prevent caking.

Learn more about rotary drum granulation system!

What kind of fertilizers can drum granulation with steam injection?

In general, the Such as compound fertilizer pellet manufacturing with nitrogen fertilizer, ammonium chloride, or ammonium sulfate, etc and NPK fertilizer production. Then, you can adjust the steam injection according to your materials. For example, increase the steam adding in the nitrogen-based compound fertilizer making with urea. But, less in complex fertilizer granulation with humic acid or bentonite.

Get your own fertilizer business plan immediately!

Is there other fertilizer granulation technology of rotary drum granulator?

Of course. For a 1-10 TPH fertilizer pellet making with drum pelletizer, it is economical to adopts the cold granulation method. It relies on the material moisture and drum rotation to granulate the powder fertilizer. There can greatly reduce the energy consumption for your fertilizer granule making plant. Additionally, this is an excellent method for the granulation of organic fertilizer and low concentration compound fertilizer.

Therefore, the rotary drum pellet machine is applied to both hot granulation and cold granulation. You can choose the technology according to the materials, capacity, etc of your fertilizer pellet making project. Here, YUSHUNXIN will offer you customized design and machines of the fertilizer production. Welcome to inquiry it immediately!