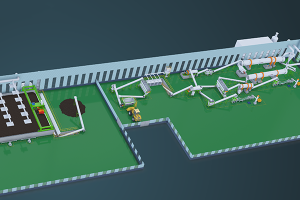

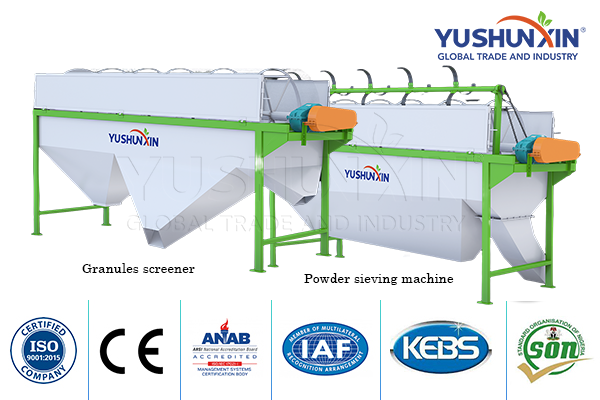

Fertilizer screening machine is an important equipment in fertilizer production line. Rotary screening machine can sift the compost material according to its particle size. If the fertilizer products are qualified, they will be conveyed to fertilizer coating machine or transported to automatic fertilizer package machine directly. Otherwise, they will go back to fertilizer crusher for granulation process again. Therefore, the role of fertilizer screener is to help you choose qualified and high quality fertilizer products in your fertilizer making process. YUSHUNXIN, as a professional fertilizer production equipment manufacture for 30 years, our products has sold all over the world and get high praise from our clients. Here, YUSHUNXIN has two kinds of fertilizer screeners for you: rotary screen equipment and vibrating screening machine

Main Parameters

- Capacity: 1-20 T/H

- Power: 3- 11 kw

- Rotary Speed: 12-21 r/min

- Screen Material: Galvanized steel

- Application Shape: Powder & Granules

What types of fertilizer sieving machines in YUSHUNXIN manufacturer?

The rotary fertilizer screener from SEEC is a new type self-cleaning fertilizer screening equipment. It is suitable for screening of various solid materials with particle size less than 300 mm. The production materials of our rotary screen machine is galvanized steel, so the service life will be long for your fertilizer production. Its screening capacity is 1 t/h-20 t/h. what’s more, SEEC can provide customized service for you. If you have any questions or requirements about the equipment, just feel free to contact us.

Rotary Fertilizer Screener for Sale

- Model: SXGS-1020

- Power(kw): 3

- Drum Speed(r/min): 21

- Screening Capacity(t/h): 1-2

- Model of Reducer: ZQ250

How about the structure of rotary fertilizer screener?

We can divide it into three parts:

Rack part

The machine frame contains high carbon steel plate and channel steel, which can pass strict product certification and meet specific technical requirements. It can reach the purpose of the machine.

Transmission and screening part

This part uses a combined screen mesh, which is transmitted through a coupling to the main shaft. The material enters from the feed end, then the roll cage will continuously turn and screen it. Finally the fertilizer will outflow evenly from the corresponding outlet. This effectively separates the finished product from the Re-material, thus improving the working efficiency.

Transmission connection part

The motor drives the pulley, the triangle belt and the reducer to make the spindle rotating. In which the drive reducer and he main working part of the main engine working under the help of the axle pin couple, it is convenient to assemble and maintain.

Technical highlights of SEEC rotary screening equipment

- High Screening Efficiency. Because the equipment has a plate-type screen cleaning mechanism design. It can never block the screen, so as to improve the screening efficiency of the equipment.

- Good Working Environment. If you need, we can provide you rotary screener with a closed dust cover. When this machine is working, there is no dust flying phenomenon which improve the working environment greatly.

- Low Noise. With sealed dust cover, the noise generated by material and rotary screen is completely isolated.

- Long Service Life. The production materials of our rotary screen machine is galvanized steel. So the service life will be long for your fertilizer production.

- Convenient Maintenance. There are observation windows on both sides of sealed dust cover. So, works can observe the operation of equipment at any time.