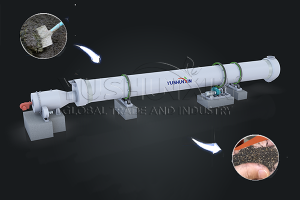

Fertilizer drying machine is a key equipment to make high quality fertilizer. Whether you want to produce organic or compound fertilizer. It is usually used after fertilizer granulating to further remove the moisture content of your fertilizer. So that your fertilizer is not easy to stick or to get mouldy. For this, YUSHUNXIN can provide you with rotary drum dryer. Combining with burner, hot blast and dust collector, it can use high temperature hot air to dry the fertilizer quickly with no pollution. So it is an ideal choice for you to reduce water content and improve your fertilizer quality. If you want to know more about it or have any special requirements, please contact us immediately.

Main Parameters

- Capacity: 1-20 T/H

- Final Moisture: <10%

- Drying method: hot air drying

- Drying Temperature: 300 ℃

- Fuel for drying: oil, gas, biomass pellets, firewood, etc

- Cost: $10,000-$130,000

- Application: Powder & Granules, animal manure, NPK, sludge, etc

Why is fertilizer drying machine essential for high quality fertilizer production

Why more and more fertilizer suppliers use drying machine in the fertilizer production line? Because fertilizer drying machine plays an important role in improving fertilizer quality.

Water content removal in fertilizer production

In general, the standard moisture content of final fertilizer is 10%. But in the production of organic fertilizer, it is usually still at about 30% after granulation. The high moisture content will reduce the quality of your fertilizer. For one thing, it will affect the strength of the fertilizer particle, so it is easy to break during packaging and transportation. For another, if the moisture is too large, the fertilizer granule will be easy to mold and deteriorate during storage. Therefore, you need to use rotary drum drying machine to process organic fertilizer in time to evaporate the excess water.

Second granulating fertilizer

Expect drying, the rotary drum dryer are also in favor of secondary granulation. It can improve the water solubility of fertilizer by increasing the temperature. Therefore, your fertilizer has good viscosity and further re-granulates. It makes the granulation rate higher and particle size more uniform.

What is the temperature when the dryer is working?

What is the working principle of rotary drum dryer?

If you want to use the fertilizer drying machine freely, it is compulsory to understand how it works. And learning the whole process of fertilizer drying also can help you improve drying efficiency.

Working process of rotary drying

The drying equipment usually makes use of high temperature environment to remove fertilizer exceed water. It uses electricity, diesel, coal and other flammable materials as power to generate heat. And transporting the hot air to the equipment by hot blast stove. Then the organic or compound fertilizer granule is in full contact with the hot air inside the equipment. And the excess moisture will be evaporated. After drying, the moisture of the material will reduce to about 10% generally.

Fertilizer mateials drying process

In this process, wet material will be sent to the hopper by belt conveyor or bucket elevator. Then it through the hopper enters the drum drying equipment. As the drum rotating, the wet material will move forward in the cylinder. And it will be in full contact with the hot air inside the equipment. Then after exceed moisture of the material is completely removed. It will be discharged from the drying cylinder and enter the next procedure.

5 Advantages of fertilizer drying equipment from YUSHUNXIN factory

If you need a equipment to drying fertilizer after granulating. The rotary drum dryer from SX is an optimal option for you. It has many advantages as follows:

High drying rate

In general, the moisture content of fertilizer without drying is about 30%. But using our fertilizer dryer, you can reduce it to below 10% in a short time. Which can fully meets the international requirement.

Various capacities for your choice

In order to meet different needs from customers, we design different capacities of dryer for your choice. From 1t/h -20t/h, it can fully meet your needs, whether you plan to produce fertilizer in a small, medium or large scale.

Lifting plate design

There are many lifting plates on the inner wall of the drum drying machine. Its function is to pick up and sprinkle down the material to make it fully in contact with hot air. So as to improve the drying rate.

Long service life

Self-aligning tug wheel structure. If you combine it with rolling ring well, you can greatly reduce wear and power consumption. So you can use the rotary drum dryer for a longer time.

Wide range of fuel sources

Our fertilizer drying machine can use biomass pellets, electricity, diesel, coal and other flammable materials as power. You can choose freely according your needs.

| Model | Motor Power (kw) | Reducer Model | Temp of lnlet (℃ ) | Angle of Installation (°) | Speed (r/min) | Capacity (t/h) |

| SXHG-0808 | 5.5 | ZQ250 | ≥300 | 3-5 | 6 | 1-2 |

| SXHG-1010 | 7.5 | ZQ350 | ≥300 | 3-5 | 6 | 2-4 |

| SXHG-1212 | 7.5 | ZQ350 | ≥300 | 3-5 | 6 | 3-5 |

| SXHG-1515 | 11 | ZQ400 | ≥300 | 3-5 | 6 | 4-6 |

| SXHG-1616 | 15 | ZQ400 | ≥300 | 3-5 | 6 | 6-8 |

| SXHG-1818 | 22 | ZQ500 | ≥300 | 3-5 | 6 | 7-12 |

| SXHG-2020 | 37 | ZQ500 | ≥300 | 3-5 | 5.8 | 8-15 |

| SXHG-2222 | 37 | ZQ500 | ≥300 | 3-5 | 5.5 | 8-16 |

| SXHG-2424 | 45 | ZQ500 | ≥300 | 3-5 | 5.2 | 14-18 |

Aspects you must pay attention to while using fertilizer drying machine

During the process of manufacturing fertilizer by drying equipment, you must pay attention to these two aspects. They can make your fertilizer production operate correctly and smoothly.

Angle of inclination

In order to make the material flow into the dryer more smoothly, the inclination angle of the feeding pipeline is generally larger than the natural inclination angle of the material. And the rotary dryer is not completely horizontal and will be tilted 3-5°. It makes the discharge of fertilizer pellets easier.

Temperature of the rotary dryer

It can be seen from the above that high temperature is important for the fertilizer drying process. But excessive heat will kill effective live bacteria. So in order to avoid the death of effective live bacteria, the temperature of pellets can not be higher than 60℃ during drying.

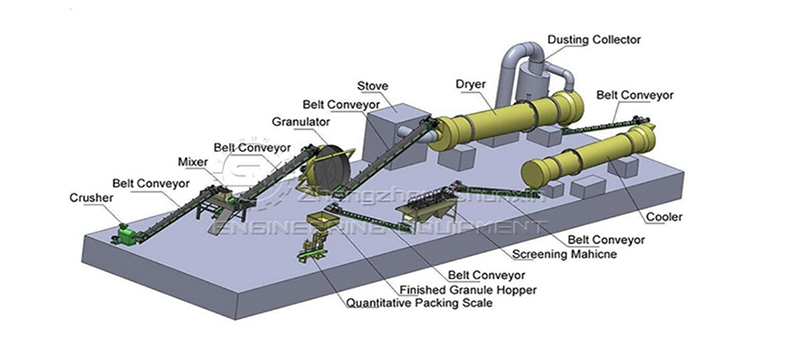

Other equipment used in the process of fertilizer drying

Besides rotary drum dryer, burner, hot blast stove and dust collector are also required for fertilizer drying. They can help you in the aspect of heat supply and pollution removal.

Fertilizer drying burner

Burner is mainly used to provide fire to generate heat for fertilizer rotary dryer. It can ensure sufficient combustion of fuel and low loss of heat. Here, we can offer you burners use fuel of oil, gas and biomass pellets.

Hot blast furance

The hot blast furance is the place to generate hot air for fertilizer dryer. It is added with manganese steel plate, and the inner lining is firebrick. So it can withstand high temperature from drying air generation. Moreover, different types can be made according to the customer’s requirements.

Dust collector

If you want to make fertilizer without secondary pollution. We recommend you to equip your fertilizer production line with dust collector. It is usually used in fertilizer drying and cooling processes to collect the dust caused by the fan. Here we can provide cyclone dust collector, water curtain dust collector and bag filter dust collector for your choice.

Why we don’t use fertilizer dryer to remove water at the beginning of organic fertilizer production

Since the fertilizer dryer can remove moisture quickly, can we use it to replace the fertilizer composter? Absolutely not. There are two reasons as follows:

Reducing cost of fertilizer drying

Cost is an important factor in what method you choose to use in the preparation of fertilizer. If you choose to use the dryer only to reduce fertilizer moisture, your production cost will become higher than combine with fertilizer composter. Because after the granulation, the fertilizer only has a water content of about 30%. In general, a fertilizer drying machine is enough to reduce it to below 14%, the standard moisture of fertilizer. But before composting, the moisture content of organic fertilizer materials can reach 70%-80%. If you want to dry them without composting equipment, you need to buy two or three rotary dryers. So you will spend more on the equipment. And your fuel cost will also increase. Therefore, it is not advisable to use the fertilizer dryer to replace composter during organic fertilizer production.

Easy to material sticking to dryer

As mentioned above, the fertilizer drying machine mainly uses high temperature to reduce the moisture content. So the temperature inside the dryer is high and the temperature of inlet air can reach 500 ℃. So if you feed the unprocessed material in it directly, it is easy to stick to the wall. This will make the production of fertilizer more difficult.

Can you offer replacement parts for the fertilizer dryer?

Of course. There are various repacement parts of fertilizer dryer available in YUSHUNXIN fertilizer equipment manufacturer factory. Including main gear, pinion gear, or trunnion wheels, riding rings, thrust rollers, etc.In addition, we can fully meet your requirements of customization on size, material, unique design, etc, because of professional manufacturing equipment.

The fertilizer rotary drum dryer is a new generation of dryer developed by our staff for many years of organic and compound fertilizer production experience. It has the characteristics of beautiful appearance, simple operation, low energy consumption, long service life, uniform drying, easy maintenance and so on. Combining with hot blast stove and dust collector, it can dry your fertilizer quickly without secondary pollution. So it is an ideal fertilizer drying machine for you to improving fertilizer quality.