Generally speaking, commercial composting equipment refers to the professional compost machines used in the compost making process. If you want to make compost for commercial purposes, YUSHUNXIN will give you the best solution for your commercial composting system. In a word, a perfect composting system should equip with pre-treatment equipment (compost crusher, mixer, feeding machine and so on), fermentation equipment (3 types), post-treatment equipment ( screening equipment, packaging machine, etc). If you have any other requirements about fertilizer composting, welcome to contact us, we will offer you the best solution.

Main Parameters

- Capacity: 1-30 T/H

- Composting Time: 15-20 days

- Moisture after composting: about 30%

- Equipment Material: Q235 Carbon steel, Manganese steel, stainless steel (can customized)

- Application: cow dung, chicken poop, pig manure, horse waste, sludge, wine lees, bagasse, etc.

How to prepare commercial compost fertilizer quickly?

How to choose a suitable machine for commercial composting?

Compost turner is the key equipment in commercial composting system. It plays an important role in fermentation process. In SX, there are many types compost turning machine you can choose for your plant. They all designed by advanced aerobic fermentation technology for composting process. When the composting temperature reach 70℃ and the compost piles need to cool and turn over, our compost turner will begin to work. In general, there are three type of commercial composting facilities that are popular with organic fertilizer compost makers.

Economical windrow composting turner

If you start a economical compost fertilizer making from organic waste, we recommend you buy SX windrow composter. It can start commercial aerobic fermentation directly on the flat ground. So you reduce you cost of infrastructure building (fermentation tank). Moreover, only by control two robs, it can help you process 300-1500 m³ of manure piles per hour, which can fully meets your requirement of small-medium composting.

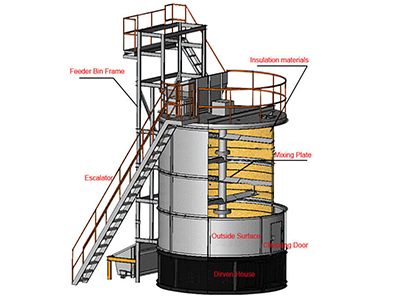

Full automatic in-vessel fermentation tank

Is there fertilizer compost equipment with a higher automation? Here, you can choose our in-vessel fermenter. This machine adopts computer control system, which has automatic material lifting. temperature monitoring, stirring, oxygen transport, etc systems. And the commercial composting is taken place in an closed environment. So you can decompose manure faster. In addition, only needs 10- 30 ㎡, a fermentation tank can finish harmless process of organic waste.

Wheel type compost turner for large scale compost making

Is there a equipment for composting a larger amount of organic waste? Wheel type composter is the best choice. Because it has a larger turning span, which can reach 10-30 m. And a higher turning depth of 1.5-3 m. It means you can compost the same amount of fertilizer with fewer grooves. So your infrastructural cost will be lower. Besides this, it also can reduce fertilizer production cost in the aspect of labor force. Because it is equipped with fully automated electric control system. Only one worker, you can control the whole compost process.

What facility is used before commercial composting?

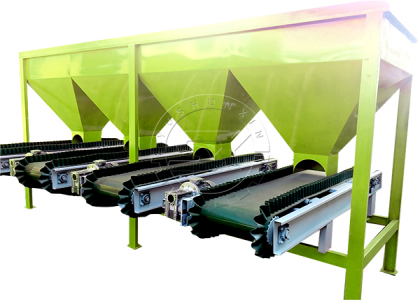

In order to make high quality compost fertilizer, you need to do something with your raw materials such as crushing and mixing. These processes are very important in the commercial composting system. It helps the raw materials become suitable for better fermentation. Pre-treatment facility mainly includes compost fertilizer crusher, mixer and feeding equipment. In the whole commercial composting process, the functions of these machines are as follows:

Increase the organic matter in raw materials

in order to prepare quality compost fertilizer, we usually need to add auxiliary organic materials in compost piles. For example, for adjusting the water and carbon to nitrogen ratio, you may add animal manure, industrial waste, sludge, etc. Or feeding straw, sawdust, corn cob, etc. Moreover, sometimes, you also need to put N, P, k and manganese, magnesium, iron, zinc micronutrients. However, in this process, the most important thing is feeding them according to required proportion. Therefore, a suitable batching machine is necessary.

Mix compost material evenly and quickly

For organic fertilizer manufacturing, ensuring nutrients balance is essential. It is the same as compost fertilizer production. In addition, this not only means rich nutrient types but also requires nutrient distribution balance. So it is advisable to mix various raw materials evenly. As a professional fertilizer equipment manufacturer, SX also provide high quality fertilizer mixing equipment for you.

Provide appropriate material granularity for fermentation

In commercial composting system, some raw materials are not suitable to be composted directly which put off the composting process. This is because their particles are too large which not meet the requirements of the composting operations. So, it is necessary to crush them into small size. In SX company, there are different types of fertilizer crushing equipment that can help you crush your raw materials. Here is the most commonly used one for compost fertilizer plant – new type vertical crusher.

How make compost into fertilizer with a higher commercial value?

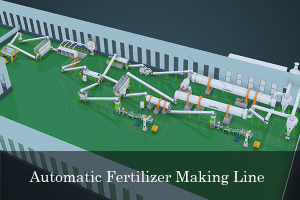

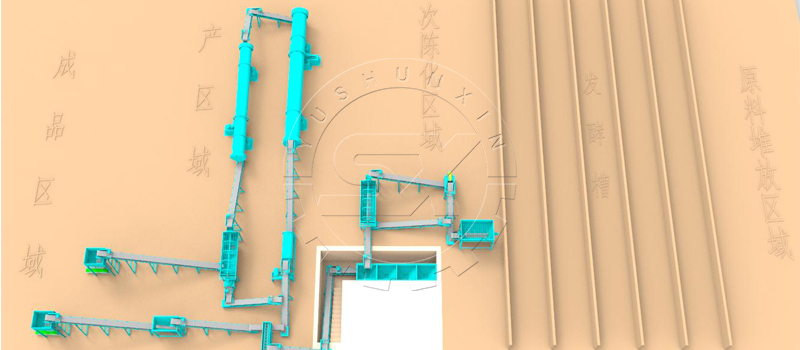

Commercial Compost Turner (raw materials fermentation) → Batching machine (add other materials required)Crusher Machine (crush composted materials in small size) → Compost Mixing Equipment (mix materials quickly and evenly in a short time)→ Organic Fertilizer Granulator (materials granulating) → Rotary Drum Dryer (fertilizer drying) → Rotary Drum Cooler (fertilizer cooling) → Commercial Compost Sifter Machine (fertilizer screening) → Chain Crusher (substandard products crushing for re-granulating) →Organic Fertilizer Coating Machine (finished products coating) → Automatic Packing Machine (fertilizer packaging) → Belt Conveyor (raw materials and finished products transporting)

As a professional fertilizer equipment manufacturer, SX can give you the best solutions about your commercial composting business plan. What’s more, we also can provide you with the most suitable fertilizer equipment for further compost fertilizer production. So, if you have questions or requirements about our products, just contact us freely!

How to start a commercial composting business?

A reliable composting business pan is very popular around the world, especially in farm. Because farms can provide you with all kinds of materials to make organic fertilizer. In order to start a commercial composting business, what you need to do? Several aspects you need to focus on.

Step1: Search sources and materials of making compost

You will need to understand what kind of material can be made into rich, natural compost, such as leaves, grass cuttings, manures and other organic materials. The science behind it is very decompose in its own time, but there are some things you need to strength your end product. Through the internet, you also know which organic materials are nutrient rich, and can be used as fertilizer, and which is aren’t suitable for this, but can still be used as soil conditioners.

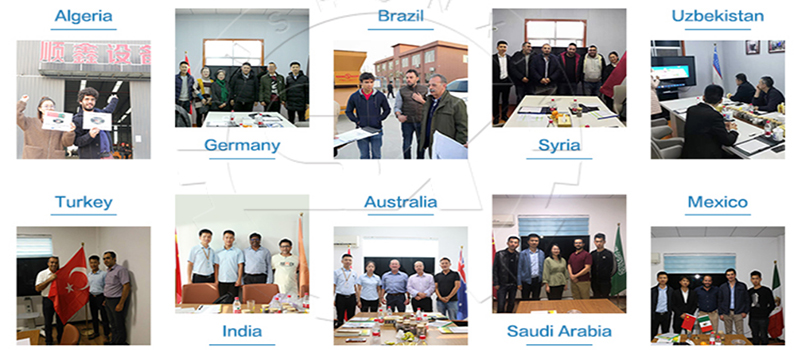

Step2: Find reliable fertilizer equipment manufactures

A reliable fertilizer equipment supplier is the key to succeed. It can help you deal with facing problems- how to operate the machine and what details you need to pay more attention, etc. To some extent, it can give you best solutions to solve your difficulties, such as the problem is that how to make 150 tons cow dung into compost. Aiming to those problems, our company can provide professional advice for you. Therefore, you can spend little time.

Step3: Distribution/Delivery

You could talk to farmers and gardeners in your local area and offer to deliver fresh , organic compost to them. They can use this for soil maintenance and depending on what materials its made from, in some cases, as a fertilizer. Then, you could have an investigation at a farmer market or gardening fair. Many gardener need use compost to give their plants the extra nutrients the need and to recondition soil. This is your target market, you can put your product out in front of them. Finally, you could set up a small e-commerce store and sell via the internet. It can give you a much wider reach, but will increase your benefits. If you want to scale up, this can be a great next step after your succeed at the local level.