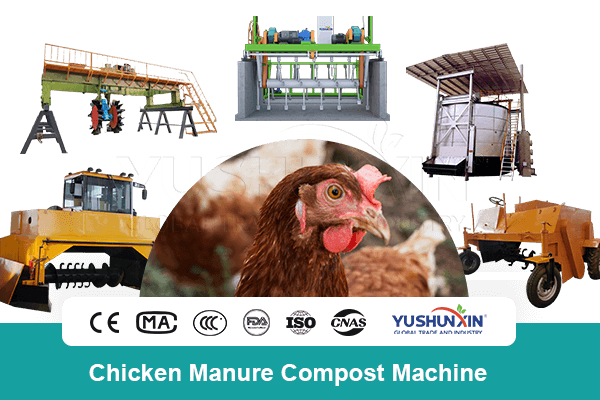

Chicken manure is a kind of good raw material in organic fertilizer making. Because it has a high nutrients content in N, P, K , which is beneficial for the growth of crops and plants. But, as manure waste, it also contains many pest eggs, pathogens and grass seeds which is harmful. Then, how to dispose of chicken poop in harmless? Composting is the first choice. For this, YUSHUNXIN especially design professional chicken manure composting system for wide range of capacity, prices, fermentation methods, etc. With them, you can decompose chicke litter quickly.

Main Parameters

- Capacity: 300-2500 m³/h

- Composting Time: 10-20 days

- Area: Depended on material quantities

- Equipment Material: Q235 Carbon steel, alloy (customized)

- [Application] cow dung, chicken poop, pig manure, biogas waste, mushroom waste, straw, rice hull, etc.

How to buy the right chicken poop composting machine?

To ferment chicken manure fast and economically, it is important to buy a right machine for your chicken manure composting system. Here, you can consider it from the following aspects:

Capacity – 1 t/h or 20 t/h?

When you plan to start a large scale chicken manure composting over 10 t/h ouput, we recommend you choose wheel type composter. Because it has a wider turning span and deeper turning depth, which can reach 8-30 m and 2-3 m. But if you want to buy a fertilizer equipment for making chicken dung compost in a small scale that less than 10 t/h. You can choose groove type compost turner, windrow compost machine and organic fermentation tank. They are suitable for preparing compost from chicken manure with an output of below 1,500 m³/h.

| Equipment | Wheel Compost Turner | Groove Compost Machine | Windrow Compost turner | Organic Fermentation Tank |

|---|---|---|---|---|

| Capacity | Turn width: 8-30 m Turning depth: 1-3 m | Turn width: 3-5 m Turning depth: 0.8-2 m | Turn width: 2.4-3 m Turning depth: 0.6-1.5 m | 5-150 m³ |

Get your own chicken manure composting machine!

Price – From $4,000 to $80,000

If you want to finish broiler manure fermentation at a low cost, groove type compost turner and moving type self-propelled composter both are an ideal choice for you. The price of them is about $4,000-$19,000. Which is much lower than other organic fertilizer compost equipment. But if you have enough budget for compost machine buying, we recommend you choose organic fertilizer fermentation pot. This machine usually processes compost in a closed environment. So it can greatly reduce the impact of the outside world conditions and help you complete chicken poop fermentation faster.

| Equipment | In-vessel compostor | Moving type compost turner | Groove Compost Machine |

|---|---|---|---|

| Pricing | $10,000-$80,000 | $4,000-$12,000 | $6,500-$19,000 |

Get precise quote of your chicken poop compost equipment!

Composting method

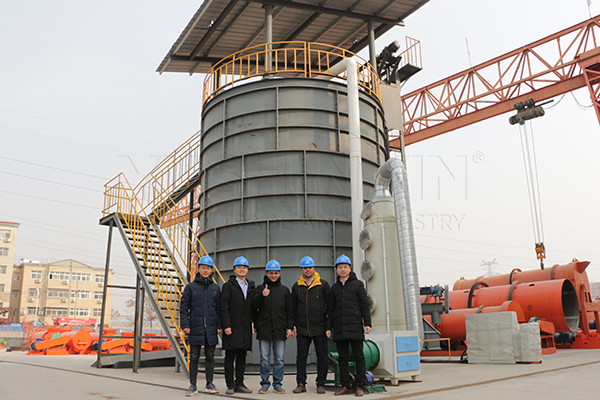

Provided you want to start broiler droppings composting in fermentation grooves, you can buy groove type composter, wheel type compost machine and chain plate compost turner. When you process chicken droppings compost fertilizer on the ground directly, we recommend you choose crawler type compost turner or moving type compost equipment. In addition, if you need an in-vessel fermentation tank, SX can offer you vertical fermentation pot and horizontal fermentation tank. Using them, you can choose to decompose chicken dropping indoor or outdoor freely.

Start your chicken dung fermentation immediately!

How to remove excessive water from fresh chicken dung before fertilizer composting?

In chicken manure composting making system, water content of materials is an item you must pay attention to. Because when the moisture content of chicken poop is below 30%, the activity of functional bacteria will be reduced. And when it is higher than 65%, the ventilation voids will decrease. This will hinder the transport and diffusion of the air in the compost. Thereby, the microorganisms in broiler poop cannot get enough oxygen to support them to decompose manure. Therefore, before starting fermenting chicken dung, it is advisable to control the moisture content to 60%-65%. But the water content of fresh chicken dung usually can reach 70%-80%, and even 90%. Then how to reduce the moisture content of manure? You can finish it in following ways:

Mixing chicken dung with dry organic waste

If the waster content of chicken poop is between 70%-80%, you can remove excessive moisture by mixing broiler dung with dry organic waste. Such as shavings, sawdust, dry leaves, or straw. They are common materials of chicken bedding, so they are easy to find in the chicken farm. You can choose to pave them on the bottom of the fermentation trench or crush them into powder and mix with chicken dung.

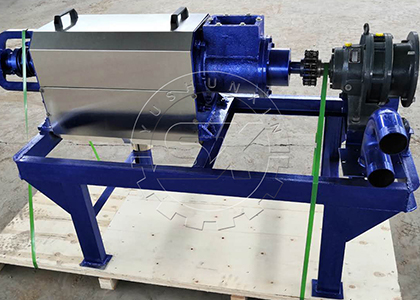

Processing chicken manure with YUSHUXNIN dewatering machine

But if you want to complete chicken droppings excessive water removal faster and more effectively. Or the moisture content of chicken poop is higher than 90%. We recommend you choose to use YUSHUNXIN dewatering machine. It can help you reduce the moisture content of broiler dung to 30%-40%, which is suitable for chicken manure composting. Then what is the maximum output of a single screw solid and liquid separator? In general, it can provide you with 15-20 ㎡ solid chicken dung per hour.

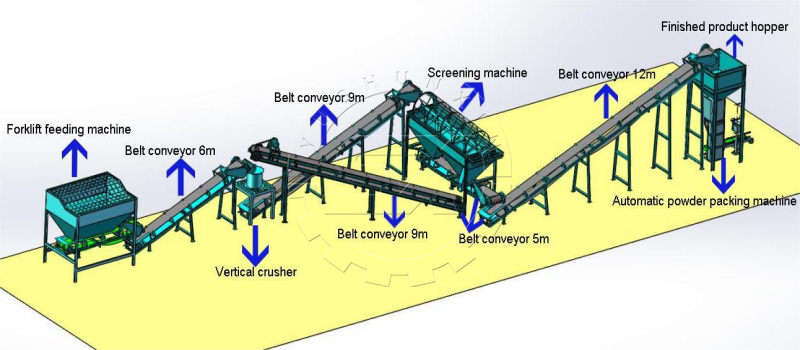

How to make compost chicken manure into powdery fertilizer?

For your chicken waste management, the best way is to convert chicken manure into organic fertilizer. If you are not familiar with composting work and need to learn the best way to compost chicken manure in your chicken farm, just feel free to contact us. As a professional fertilizer equipment supplier, YUSHUXNIN can help you design and manage a chicken manure composting system to compost chicken manure easily. If you want to make powdery organic fertilizer from chicken waste, the following making process may help you finish it. First, use our groove type compost turner to compost chicken manure and straw. Then, crush the composted materials into small size and screen them carefully. After that, according to your needs, you can add other trace elements and mix them with the disc mixer. Finally, package the final powdery compost products.

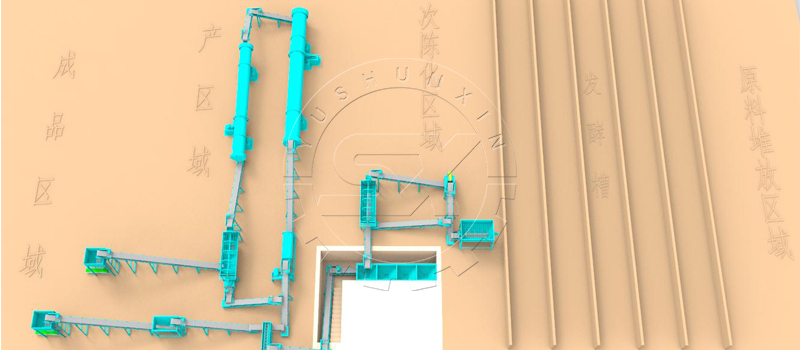

Commercial chicken manure compost production line

This production line is designed to make chicken manure compost into granules for commercial purpose. It is mainly consist by the fermentation system, batching system, pulverizing system, mixing system, granulation system, drying system, dust removal system, screening system, and finished product packing system. If you have any requirements about this production line, it can be customized for you.

How to compost chicken manure quickly in your poultry farm?

Hot composting is the fastest method to compost chicken manure. Deal to the high temperature in aerobic fermentation process, aerobic decompose is also hot composting. Besides, ideal composting conditions can accelerate the chicken manure composting process. If you want to compost chicken manure fast in your poultry farm, the following recipes may help you:

Tips 1. Crush the raw materials into small size.

Before composting, crush the raw materials into small size can increase the working area with oxygen. During aerobic fermentation process, organic mater will decompose more quickly. Here, YUSHUNXIN has compost crusher for your crushing work.

Tips 2. Adjust the C:N ratio.

Carbon and nitrogen are essential elements in the chicken manure composting process. If you want to compost chicken manure quickly, you need to pay attention to the C:N ratio of your raw materials. Generally speaking, when the C:N ratio of raw materials is (25-35):1 the fermentation process will be fastest.

Tips 3. Turning compost piles when it is necessary.

During the chicken manure composting process, it is necessary to turn and stir the compost materials. It allows air to enter and the good bacteria need some fresh air to continue working. YUSHUNXIN has different kinds of compost turning machines for sale, you can select a suitable one for your chicken manure composting system.

Where you can get high quality chicken manure composting system?

As we mentioned above, chicken manure composting system with high quality is very popular around the world. It can offer you best solution in making chicken manure into compost quickly. However, how and where to chose the best and high quality fertilizer equipment manufacture is the key to succeed. YUSHUNXIN fertilizer equipment factory will give you some important tips for you.

- In terms of professional experience, they need 20 years experience in fertilizer equipment industry. By this way , it reduces investment. Because engineers can give you professional advice and best solution in a short time.

- In terms of cost of investment, you need choose a manufacturer, not an agency. Because for third parties, they make the gap between supplier and buyer. However, as a manufacture, the price is lower than third parties.

- In terms of service, one stop service ad custom service are necessary to estimate a company whether good or bad. Therefore, when you choose , please pay more attention on those.

Aiming to three points, our company, YUSHUNXIN, is best suitable for your choice. Welcome you to visit.