По данным прошлого, есть 3 типы решений для проекта по производству органических удобрений пользуются популярностью у поставщиков органических удобрений. Это системы гранулирования органических удобрений., Линии по производству порошкообразных органических удобрений и планы по переработке удобрений из коровьего навоза.

Приходите и получите индивидуальную линию по производству органических удобрений!

Вершина 1: Low investment powdery organic fertilizer production lines

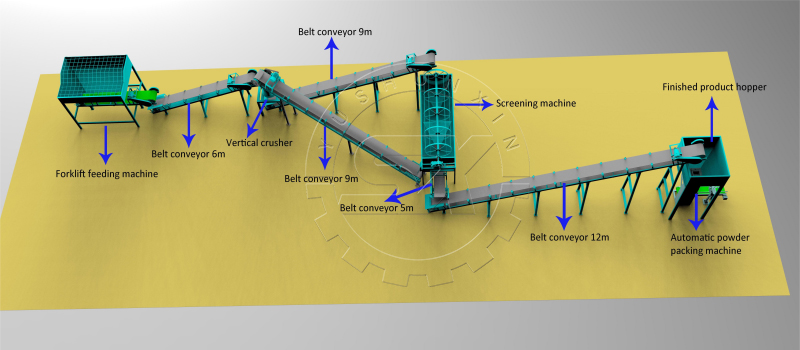

Because of the cost of organic fertilizer making is low, тот powder organic fertilizer production lines is top 1 popular with manufacturers. Как следует из названия, it is a process of making organic waste into powdery fertilizer. Only several fertilizer machines, you can produce high quality organic fertilizer. It mainly consists of five steps.

- Первый, fertilizer composting machine can help you kill harmful substances in organic materials byаэробная ферментация. Such as pest eggs or grass seeds. Then the raw material will be transported into the forklift feeder and remove big rocks and waste.

- Then using crushing equipment to grind material agglomerate into fine powder.

- And powder fertilizer screener to separate qualified powdery fertilizer and the unqualified.

- Окончательно, packaging machine will bag them.

It is the simplest manufacturing line of organic fertilizer, which contains fewer fertilizer processing machines. So it has characteristics of less space (800-5000 ㎡), low cost ($35,000-$90,000), easy operated, и т. д.. Но, it can fully meet you requirements of 1-20 t/h both small scale organic fertilizer production and the large one.

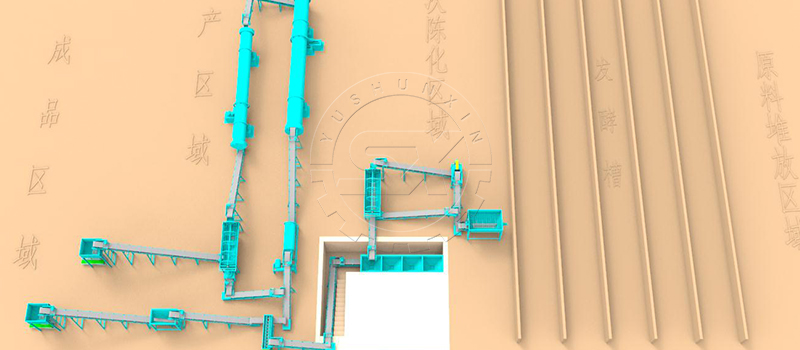

Вершина 2: Organic fertilizer granulation plan for more profits making

If you want to further produce quality of your organic fertilizer, you can turn powder fertilizer into granules. После гранулирования, the produced organic fertilizer has less contact area with each other. This can greatly prevent sticking and nutrients layering. Кроме того, it has the feature of slower nutrient release. Так, organic fertilizer production lines of granules bring you stronger competitive and more profits.

Our organic fertilizer granule making system is designed for this. On the basis of powder fertilizer manufacturing, it also needs many other equipment for organic fertilizer processing. Например,

- Organic fetilzier granulating equipment, как следует из названия, is used to turn powder organic fertilizer into pellets.

- Сушилка and cooler can further remove moisture from particles to make it meet the international requirement of 14%.

- Then coating equipment will add a protective film to prevent nutrient loss and increase the utilization rate.

Кроме того, In order to fully meet your requirement, we especially design no drying roller granulation plan, small scale disc granulator system, rotary drum pellet making line с большой емкостью, и т. д..

Вершина 3: Cow dung fertilizer production line for manure waste management

With the development of animal husbandry, animal manure disposal has been a big difficult. The same as cow dung treatment. В это время, converting it into fertilizer is an excellent choice.

Для этого, we design specialized fertilizer making line for cattle litter. It can help you turn cow dung into high quality organic fertilizer quickly. Besides the powder cow manure organic fertilizer production lines and cattle waste fertilizer granulation system, есть также liquid fertilizer manufacturing plan of cow dung. Welcom to contact us for them now!

The above is the top 3 hot sale organic fertilizer making lines from SX в 2024. And except for them, there are many other high quality fertilizer processing lines on sale. Например, chicken manure fertilizer preparing system, линия по производству комплексных удобрений, NPK fertilizer manufacturing line, и т. д.. Если они вам интересны, пожалуйста, свяжитесь с нами. We will provide you with high quality fertilizer processing machines at an favourable price.