Powdery organic fertilizer production line is the simplest method to make organic waste into fertilizer. Только 5 шаги, you will produce high quality organic fertilizer. Компостирование, material batching, сокрушительный, сортировка и упаковка. Whether you want to dispose of cow dung, куриный помет, goat crap or mushroom waste, и т. д., он может полностью удовлетворить ваши потребности. Кроме того, В общем, it has characteristics of less space occupation, low cost, простота в эксплуатации, и т. д.. Поэтому, there are many fertilizer manufacturing beginners invest in the project. Если вам это интересно, welcome to contact us for more details.

Основные параметры

- Емкость: 1-20 т/ч

- Product: Пудра

- Расходы: $10,000-$90,000

- Дизайн: переворачиватель компоста, feeder, дробилка, экран, упаковочная машина, и т. д.

- Материал оборудования: Углеродистая сталь Q235/сплав

- Приложение: Cow dung, куриные какашки, свиной навоз, козий навоз, и т. д. для удобрений

4 Advantages of making organic fertilizer into powder

When disposal of animal manure waste into organic fertilizer, powdery organic fertilizer making line is an excellent choice. Особенно, if you are beginner for organic fertilizer production. Почему? Because it has advantages of favourable price, less area needed, easy operation and various organic waste disposal.

Why composting organic manure is the first step in powdery organic fertilizer production line?

But before preparing powdery organic fertilizer, there is a necessary step required. It is organic manure composting and fermentation. Во время этого процесса, microorganism in manure material will decompose organic matters and generate high temperature to kill harmful bacteria, pest eggs and grass seeds. So organic waste will no longer produce odor and endanger the health of animals and humans. Таким образом, it is suitable for organic fertilizer making. But how to make organic compost well? YUSHUNXIN compost machine can help you a lot. It can keep the temperature of organic material at 65-70℃, which is the optimum temperature for fertilizer fermentation. And we design various industrial compost machines на ваш выбор.

Large scale fertilizer compost machine

If you have a large scale composting, we will recommend you вращатель компоста колесного типа. Because it can process fertilizer compost in the fermentation groove with a width of 10-30 m and a depth of 1-3 м. Which is higher than other organic fertilizer compost turners. Кроме того, we replace single turning wheel with double turning wheels. Таким образом, it can provide you with a better fermentation effect of your large scale organic manure processing.

Small scale fertilizer fermentation equipment

But when you plan to prepare organic fertilizer in a small scale, ворошитель компоста is the best choice for you. В общем, it can fully meet your requiremnets of processing 500-1500㎡ of organic material long windrows per hour. Более того, it adopts the ground fermentation method, which can greatly reduce the cost of fermentation trench infrastructure building.

Faster fertilizer fermentation tank

Более того, ты можешь выбрать ферментационный резервуар для органических удобрений. Which is suitable for faster organic fertilizer compost making small space manure fermentation. It usually starts composting in a closed environment, which can isolate the outside world influences. Используя его, you can complete the harmless process of organic litter within 10 hours. What’s more, we especially equip it with gas treatment system, which can meet your requirements for environmentally friendly compost manufacturing.

| Оборудование | Емкость | Comosting Time | Область (㎡) | Open / Closed |

|---|---|---|---|---|

| Колесный тип ворошилки для компоста | 10-20 т/ч | 15-20 дни | Depend on capacity | Open |

| Windrow Compost Machine | 25-750 м³/ч | 15-20 дни | Depend on capacity | Open |

| In-vessel Compostor | 5-150 m³/batch | 10-15 дни | 10-30 ㎡ | Closed |

How to ensure processing required powdery organic fertilizer?

After compost preparation, the first step of making powdery organic fertilizer is materials feeding. В это время, using a forklift to transport composted material is an excellent choice for you. You need to feed compost into вилочный питатель (is also known as loader type feeder), which plays a role of temporary storage place. It is also a bridge to contact fertilizer compost making with powdery organic fertilizer production line.

And can it be blocked by compost material as an organic compost feeder? Конечно, нет. Our engineers especially improve its designs to prevent blocking. Первый, it has a filter mesh on the top to remove big rocks, cakes and grass. And we also increase the inclined angle of wall and the size of discharge port to make material fall quickly. Кроме того, in order to prevent material from wall sticking, we equip it with stirring shaft and vibrating motor. Поэтому, the material will not block the discharge port.

How to eliminate agglomeration and caking during powdery fertilizer manufacturing?

When you turn compost into organic fertilizer powder, you will find that there is agglomerate and caking in the organic material. It will affect the use of finished powdery organic fertilizer and reduce the buying willingness of customers. So you need to crush it into fine powder. Здесь, professional fertilizer crushing machine can help you a lot. And for organic fertilizer production, we recommend you to choose vertical crusher and semi-wet material crusher.

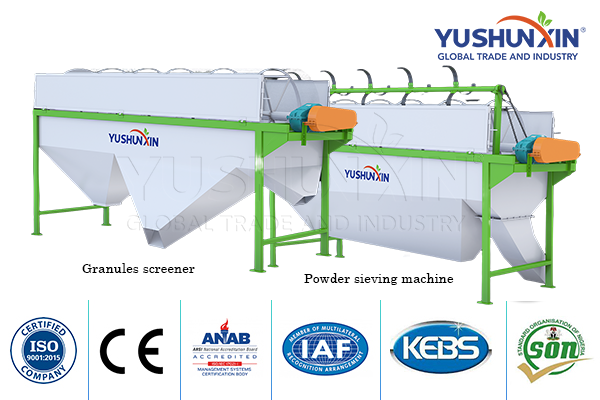

How to separate qualified powdery organic fertilizer from the unqualified?

After crushing, you may find that the powdery fertilizer may still contain some small agglomerate which doesn’t meet your requirements. Then how to separate it from qualified organic fertilizer powder? Для этого, we design specialized rotary drum screening machine for powdery fertilizer. It has two discharge ports, one is used to discharge qualified powdery fertilizer and another is designed for unqualified output. Then the unqualified products will be returned to process again. So rotary drum screening machine plays an important role in powdery organic fertilizer making.

What other equipment is needed for powdery organic fertilizer production line?

Besides the above fertilizer equipment, does it need any other machines in the production of powdery organic fertilizer? Конечно, besides forklift feeder, crushing machine and powder screen machine, packing equipment and belt conveyor also contribute greatly to high quality powdery fertilizer manufacturing.

Packaging equipment

Packing is the final step of powdery organic fertilizer production line. В этом процессе, YUSHUNXIN packaging machine can help you finish powder bagging easily and quickly. Because it can bag powdery organic fertilizer automatically and quantitatively. And the quantitative precision of the system can reach 2‰. Кроме того, it adopts the integrated structure, which can finish packing and sealing simultaneously. Only two workers, you can complete all powdery fertilizer bagging work.

Ленточный конвейер

Belt conveyor is necessary for all kinds of fertilizer production lines. Including powdery organic fertilizer making line. Because it is the bridge between the two machines to transport organic materials from one equipment to another. And in order to meet the different requirements from customers, we design various sizes of belt conveyors. Their belts are all made of anti-corrosion rubbers to ensure it has a long service life.

Lastest successful cases of powder organic fertilizer plant setup

Is there operational power fertilizer production plant for reference? Конечно. Over past 20 годы, we had helped many powder fertilizer manufacturers start their business successfully. Такой как 2000 cows dung to powder fertilizer in Mexico, digestate waste powder fertilizer production in Uruguay, и т. д..

What can YUSHUNXIN provide you for powdery organic fertilizer production?

After deciding to buy powdery production line, you must consider where to purchase it? And which fertilizer equipment supplier is reliable? SX will be an excellent option for you, because it can offer you help as follows:

Full range fertilizer machines

From pre-composting to packing, SX can provide you with all equipment of a complete fertilizer manufacturing line. Whether you need machine for powdery or granule, organic or compound, small scale or large scale fertilizer making, we can offer you best equipment.

Выгодная цена

SX can provide you with high quality fertilizer machine at a favourable price. Because it has advanced technology on fertilizer machine manufacturing, which can reduce the cost. Кроме того, it is the source factory of fertilizer equipment, so there is no extra charge you need to pay.

Customized project design

If you don’t know how to configure your fertilizer plant, we can offer help in this aspect. Only you tell us the information about material, Заводская площадь, емкость, бюджет, и т. д.. We will freely design project according to your requirements.

Considerate after-sales service

After-sales service is also an reason why so many fertilizer makers choose SX. After the sale, we can provide you with guidance on how to use the machine correctly and how to maintain it. If you have any difficulty in your fertilizer making, you also can contact us for a solution.

If you want to further making powder into organic fertilizer granules, there are also many solutions for you in YUSHUNXIN. Такой как economical roller press granulation line, small scale disc pelletizer system, large scale rotary drum granulation plan, и т. д.. Кроме того, also liquid organic fertilizer making line для тебя. Welcome to contact us for your own fertilizer making machines and business plans now!