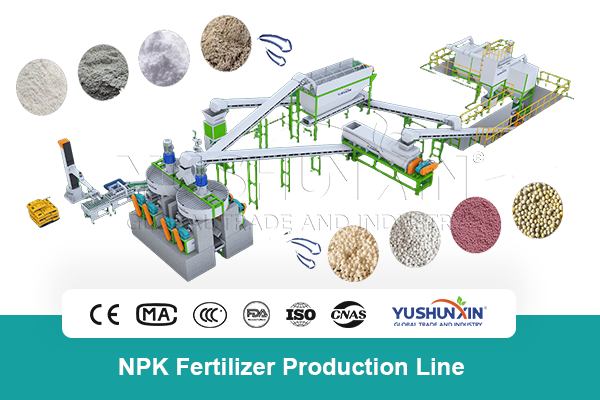

Линия по производству NPK-удобрений – это своего рода линия по производству сложных удобрений. Это может помочь вам производить высококачественные NPK-удобрения в необходимой пропорции.. В общем, есть два плана подготовки NPK для производителей промышленных удобрений.. Это линия гранулирования NPK-удобрений и система сыпучих смешанных NPK-удобрений.. Насколько велик ваш бюджет на проект по производству NPK-удобрений? $500,000 или $30,000. Требуется ли вам решение с высокой прибылью в долгосрочной перспективе или быстрая окупаемость. ЮШУНЬСИНЬ предложим вам индивидуальный дизайн.

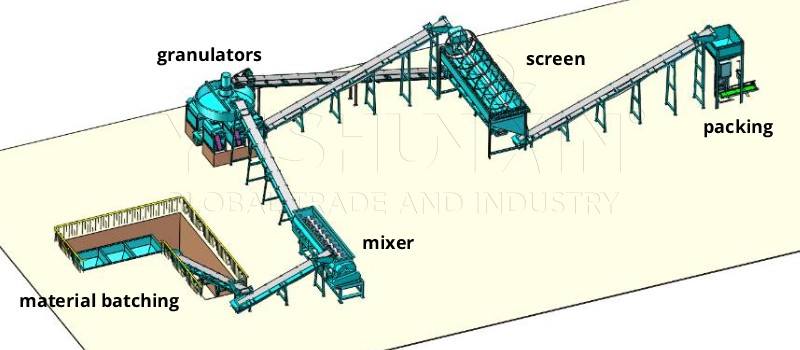

Линия грануляции NPK

| Емкость | 1-20 т/ч |

| Приложение | Химический порошок для гранул NPK |

| Дизайн | Дозационная машина, дробилка, миксер, гранулятор, экран, упаковщик, и т. д.. |

| Материал оборудования | Углеродистая сталь Q235, Сплав |

| Напряжение | 220В/380 В/415 В/440 В/480 В(50Гц/60 Гц) |

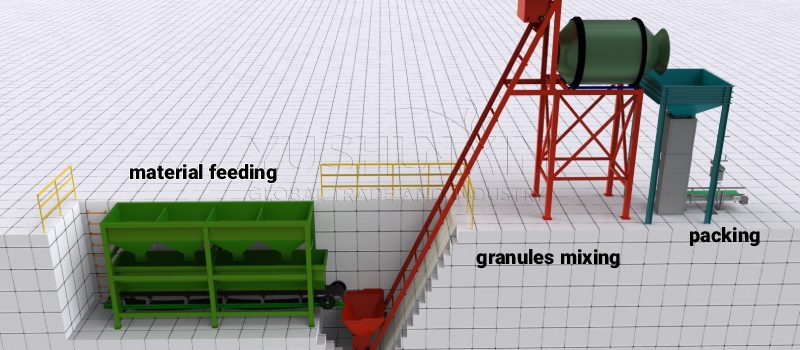

Линия для смешивания NPK

| Емкость | 5-40 т/ч |

| Приложение | Химические гранулы для NPK-удобрений |

| Дизайн | дозирующая машина, Миксер для удобрений BB, упаковочная машина |

| Материал оборудования | Углеродистая сталь Q235, Сплав |

| Напряжение | 220В/380 В/415 В/440 В/480 В(50Гц/60 Гц) |

Сколько стоит линия по производству комплексных удобрений NPK?

Вершина 2 промышленные линии по производству NPK-удобрений на ваш выбор

Обычно, начать бизнес по производству NPK-удобрений, Вы можете свободно производить гранулы NPK и смешанные удобрения NPK.. Первое может помочь вам получить больше прибыли в долгосрочной перспективе, а второе — лучший выбор для более быстрого возврата ваших инвестиций в проект по производству NPK-удобрений..

Выгодная линия гранулирования NPK-удобрений

Если вы хотите производить удобрения NPK более высокой стоимости, это идеальный выбор для покупки линии гранулирования порошка.. С несколькими этапами обработки, вы можете производить качественные гранулированные NPK-удобрения со сбалансированным составом питательных веществ., лучший выпуск и более длительное хранение. Так, Вы можете заработать больше при долгосрочной эксплуатации установки грануляции NPK.

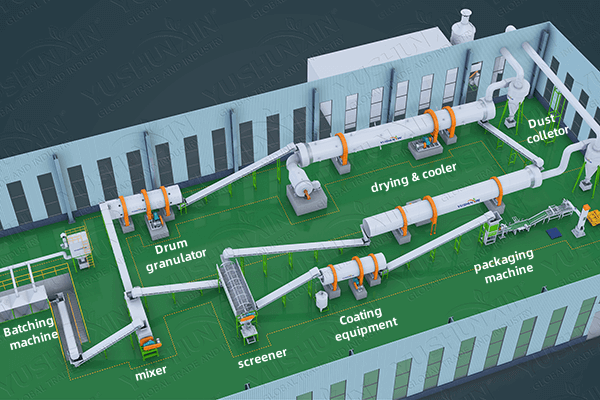

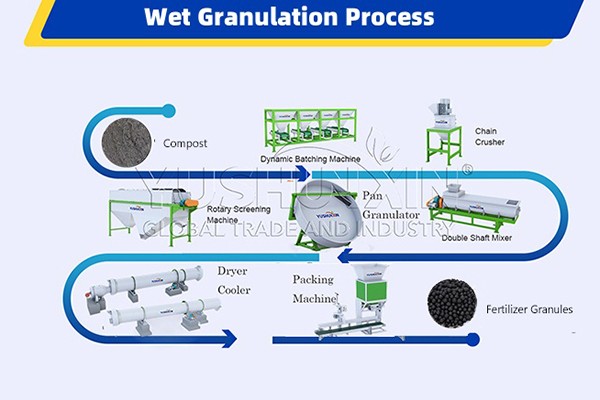

Эта система содержит этапы пакетирования, сокрушительный, смешивание, грануляция, сушка, охлаждение, скрининг, покрытие и упаковка.

- Точное дозирование – основа производства NPK строго по вашей формуле..

- Дробление и смешивание способствуют получению однородного питательного вещества, содержащего NPK..

- Гранулирование, сушка, охлаждение обеспечивает меньшую вероятность прилипания.

- Покрытие может улучшить эффект высвобождения и внешний вид..

Линия для смешивания удобрений с быстрым возвратом NPK

Но если ваш бюджет на производство NPK-удобрений ограничен, мы рекомендуем вам выбрать линию смешивания удобрений NPK. Он также известен как производственная линия для массового смешивания. Только с $100,000 Стоимость проекта по производству NPK-удобрений, вы можете начать производство смешанных удобрений производительностью 20 тонн в час.. Здесь, это может принести вам возврат инвестиций с 1-2 годы.

Это работает путем пакетной обработки, смешивание и фасовка, только 3 шаги, изготовить для вас высококачественные промышленные NPK-удобрения. Более простой процесс означает меньше занимаемого пространства и меньше Машины для внесения удобрений NPK работа. Таким образом, вы можете начать приготовление NPK-удобрений с меньшими затратами..

Может ли он производить удобрения NPK в больших масштабах?? Конечно, максимальная производительность нашей линии по смешиванию NPK может достигать 100 т/ч. Более того, хотите ли вы приготовить комплексное удобрение NPK 15-15-15 или 20-10-10, он может полностью удовлетворить ваши потребности.

Какой процесс гранулирования порошка лучше для приготовления NPK-удобрения??

Для изготовления пеллет NPK, Производители обычно используют два процесса гранулирования удобрений.. Технология сухой грануляции и метод влажной грануляции.. Они могут полностью удовлетворить ваши требования к линии по производству гранулированных NPK-удобрений с 1-20 мощности ТПХ, 1-10 мм гранулы, $50,000-$500,000 бюджеты, 500-10,000 ㎡ занятость территории, и т. д..

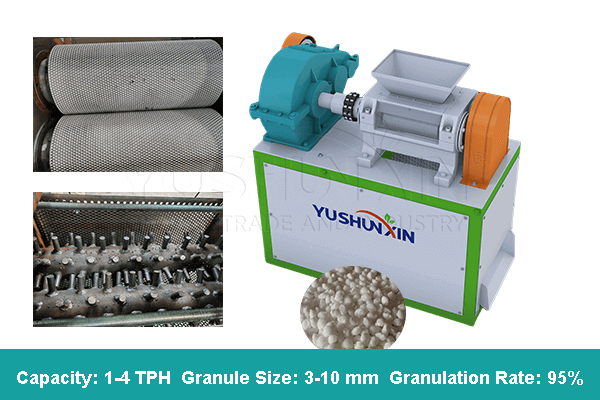

Технология сухой грануляции порошка NPK

Если вам нужна промышленная линия гранулирования комплексных удобрений NPK производительностью 1-10т/ч., более низкая стоимость, и ограниченная территория, тот технология сухой грануляции экструзии с двойным роликовым прессом может удовлетворить ваши потребности. С менее чем 10% влага NPK порошок, тот линия грануляции с роликовым прессом гранулируют его главным образом механическим давлением. А именно, необходимо добавить воду и осушитель, круче к вашему плану гранулирования NPK-удобрений. Поэтому, для 1-20 Создание линии по производству сжатых гранулированных NPK-удобрений TPH, вам нужно всего лишь подготовить бюджет $50,000-$300,000 и мастерская 800-3,500 ㎡.

Метод влажной грануляции комплексного удобрения NPK

Но, для тех, кто хочет производить NPK-удобрения в гранулах в больших объемах и с более сбалансированным содержанием питательных веществ., круглая форма шара,и т. д., системы принимают метод влажной грануляции твой отличный вариант. С естественной ротационной грануляцией, он может идеально перерабатывать большое количество порошка NPK в сферические гранулы удобрений при глубоком смешивании материалов.. В то же время, во время грануляции, он использует воду и жидкие добавки, поскольку связующие вещества помогают быстро гранулировать NPK-удобрения, а размер свободно регулируется от 1 до 8 мм.. Здесь, YUSHUNXIN может предложить вам и то, и другое. система гранулирования в чаше с более чем 93% скорость грануляции и план грануляции во вращающемся барабане максимального 30 Производительность т/ч. Что касается Стоимость изготовления NPK удобрений и земля, это требует около $300,000-$500,000 затраты и 4,000-10,000 ㎡ мастерская.

Или, вам нужны любые другие требования для производства гранул удобрений NPK, YUHSUNXIN также может предложить ваши индивидуальные решения., приди и возьми это сейчас!

Можете ли вы предложить $200,000 Стоимостные решения по строительству завода по производству азотно-фосфорных удобрений?

Да, абсолютно. Как профессиональный производитель, специализирующийся на решениях и оборудовании для производства удобрений., YUSHUNXIN предоставляет гибкие и экономически эффективные планы производства NPK-удобрений, адаптированные к вашему конкретному бюджету и требованиям мощности.. Для клиентов, желающих инвестировать около $200,000, мы можем разработать несколько практических вариантов, которые сбалансируют эффективность производства, уровень автоматизации, и масштаб вывода.

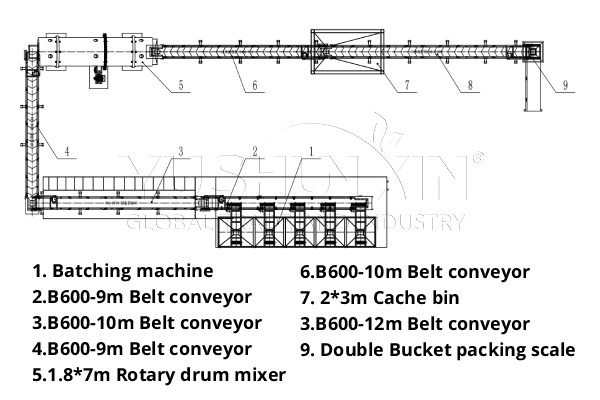

30Система внесения смешанных NPK-удобрений TPH

Если вы хотите установить автоматическую линию по производству NPK-удобрений в больших масштабах., Лучше всего купить систему массового смешивания гранул.. Имеется полная конфигурация динамического дозатора. (индивидуальные бункеры для 2-6 или больше), 1.8*7м вращающийся барабанный смеситель, кэш-хранилище, double bucket bagging machine and conveyors. Конечно, вся система контролируется контейнером ПЛК, которые помогут вам производить комплексные удобрения NPK с меньшим количеством рабочих.

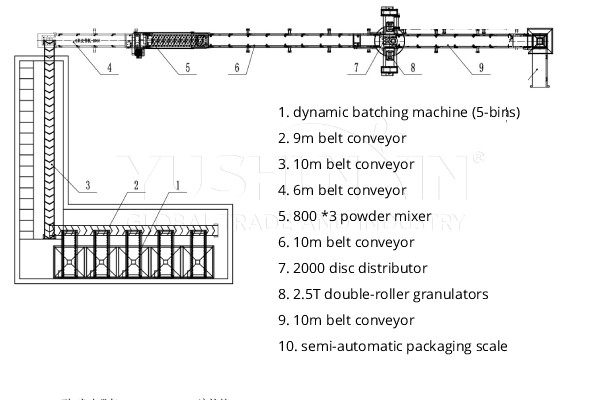

5Линия гранулирования удобрений TPH NPK

Можем ли мы производить гранулы NPK из порошка с $200,000 инвестиции в оборудование? Конечно. Вы можете настроить полуавтоматическую линию гранулирования с двумя роликами.. It only contains NPK fertilizer equipment of dynamic batching machine (5-bins), SXSJ-0830 двухвальный смеситель, Дисковый распределитель SXJP-2500, SXDG-2.5T роликовый экструзионный гранулятор*2, оборудование для упаковки гранул, и 4-6 sets of belt conveyors. В будущем вы можете модернизировать систему производства пеллет NPK..

Кроме того, there are customized solutions to NPK fertilizer making project with $100,000 инвестиции, $300,000 cost, $500,000 бюджет, и т. д.. Приходите за ними сейчас!

Past projects of Commercial NPK fertilizer production

Теперь мы помогли многим производителям NPK-удобрений успешно начать подготовку NPK-удобрений.. Будь то маленький или крупный масштаб, Порошок NPK в гранулы или производство удобрений из смеси NPK, и т. д.. Некоторые случаи приведены здесь для справки..

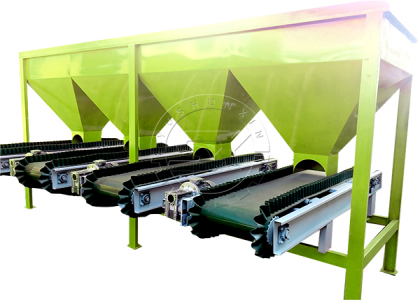

Как повысить точность дозирования NPK-удобрений?

Почва и урожай в каждом регионе разные.. Таким образом, потребности в питательных веществах N, П и К разные. Поэтому вам следует приготовить комплексное удобрение NPK в определенной пропорции.. Это решено по результатам расследования. Поэтому точность подачи NPK-удобрений имеет важное значение.. Есть несколько машин NPK, которые могут помочь вам в этом аспекте..

Динамический автоматический дозатор

Если вы хотите повысить точность подачи порошка NPK линии гранулирования NPK-удобрений.. The динамическая автоматическая система дозирования это оптимальный вариант для вас. В качестве измерительного оборудования обычно используются электронные конвейерные весы или ядерные весы.. И хост имеет ПИД-регулирование и функцию сигнализации.. Он может обеспечить непрерывное дозирование без промежуточной остановки.. Таким образом, он может удовлетворить строгие требования к пропорциям различных материалов..

Смеситель удобрений BB в линии смешивания удобрений NPK

В процессе смешивания NPK-удобрений, есть другое оборудование, которое поможет вам повысить точность дозирования. Это смеситель удобрений BB., который играет важную роль в производстве высококачественных NPK-удобрений.. Он преодолевает явления смешанной хроматографии и распределения.. Это вызвано различной пропорцией сырья и размером частиц.. Тогда свойства материала, механическая вибрация, давление воздуха, Колебания напряжения и холодная погода больше не могут влиять на систему. Так что ждем только 3-5 минут, Вы можете получить необходимое вам NPK-удобрение.

Преимущества линии по производству пеллет NPK на заводе по производству удобрений SX

Бюджетный

Мы можем предоставить вам линию по производству NPK-удобрений по идеальной цене.. Потому что Shunxin является производителем оборудования для удобрений.. И мы можем бесплатно разработать проект по производству NPK-удобрений в соответствии с вашим бюджетом.. Это может значительно снизить ваши производственные затраты..

Длительный срок службы

Все оборудование для переработки NPK, которое мы вам предоставляем, изготовлено из высококачественных материалов.. Более того, мы предложим вам руководство. В том числе о том, как правильно использовать оборудование для внесения удобрений и как его обслуживать.. Они важны для продления срока службы оборудования НПК..

Простое управление

Нанимаем только несколько работников, вы можете поддерживать работу всей производственной линии. Поскольку система машин NPK отличается высокой степенью автоматизации.. Самая маленькая линия NPK-удобрений в нашей компании требует всего лишь 3-4 рабочие.

Производить высокоэффективные удобрения

Он принимает передовые технологии и разумный дизайн.. Они за строгое производство NPK-удобрений в необходимых пропорциях.. Таким образом, готовое удобрение содержит богатые питательные вещества., в том числе азот, фосфор и калий и другие элементы. И это может эффективно способствовать росту урожая..