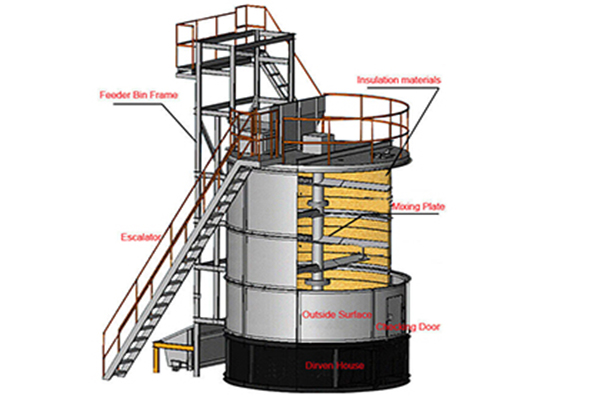

Vertical fertilizer fermentation pot is a key equipment to make high quality organic fertilizer. It is widely used in composting organic waste so that it is harmless to make organic fertilizer. The machine mainly adopts in-vessel composting method and employ professional waste gas treatment system. Поэтому, it is an ideal choice for no odor and fast fertilizer composting. Кроме того, only need an area of 10-30 ㎡. If you need more details or have any special requirements, also can contact us immediately for customization.

Основные параметры

- Емкость: 5-150 м³

- Метод компостирования: Компостирование в емкости

- Время компостирования: 10-15 дни

- Area Occupation: 10-30 ㎡

- Feed Material Moisture: 50%-60%

- Heating Power: 4 кВт

- Stirring Power:7.5-11 кВт

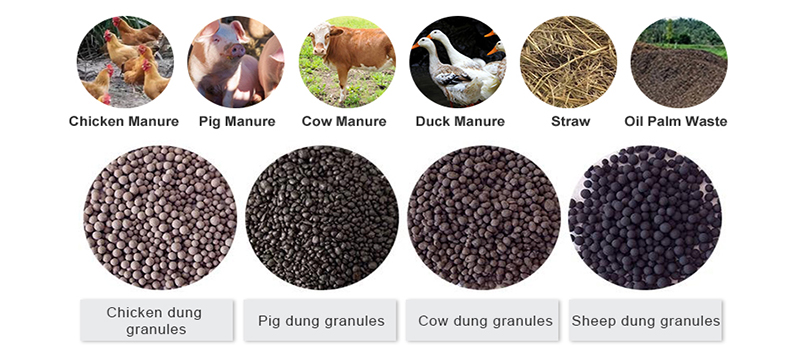

- Приложение: Chicken poop, коровий навоз, свиные отходы, биогазовые отходы, грибные отходы, солома, рисовая шелуха, humus, и т. д..

3 Designs of vertical fermentation tank can help you compost organic fertilizer faster

Vertical fermentation pot is a kind of commercial composting equipment. It plays an important role in the production of high quality organic fertilizer. It has many elaborate designs, which can make organic fertilizer fermentation better and easier.

Temperature sensor

In order to regulate the temperature timely, our engineers especially design a temperature sensor for organic fermentation pot. It can real-time monitor the tank inside temperature when the organic manure fermented in the fermentation tank. So you can regulate the temperature without delay. Более того, the temperature sensor can adjust the temperature by starting on the industrial electric blanket. Which is embedded in the two-layer tank wall. Поэтому, you can keep the inside temperature at 60℃-70℃ easily. It is the best living temperature for organic fertilizer composting.

Air heating device

Air heating device is another design to make sure that the temperature in the tank is suitable for organic fertilizer fermentation. The heating device is in the upper side of the fermentation tank. It can heat the oxygen that is pressured into the tank.

Roots blower

Expect temperature sensor, there is also an oxygen sensor that can monitor oxygen concentration in the tank. If the oxygen is not enough, you can use high pressure Roots blower to press the heated oxygen into the fertilizer fermenter. So you can make sure that aerobic bacteria has enough oxygen. Then it can work better to decompose and compost organic fertilizer.

| Модель | Heating Power (кВт) | Stirring Power (кВт) | Feeding Type | Размеры |

|---|---|---|---|---|

| SXFT-10 | 4 | 11 | belt conveyor | 2400x2400x6900 |

| SXFT-20 | 4 | 18.5 | belt conveyor | 3100x3100x6500 |

| SXFT-30 | 4 | 7.5 | Feeding bucket | 4000x4000x7000 |

| SXFT-100 | 4 | 7.5 | Feeding bucket | 5000x5000x8500 |

How about the final product processed by vertical organic fertilizer fermenter

The good fermented material is the most indirect evidence to show the high quality of fertilizer composting equipment. You can observe it from three parts: содержание воды, PH value and C:Коэффициент N.

Water content

Как упоминалось выше, the moisture of the material before fermentation is 50%-60%. But the moisture content of qualified organic fertilizer is 14%. В этом случае, our organic fertilizer fermenter can reduce the water content to 30%. Затем гранулирование удобрений, сушка, охлаждение, etc can further remove moisture from your organic fertilizer. The water content of final fertilizer can reach below 10%.

PH value

The PH value of the soil is important for plant growth. If it is too high or too low, the growth of the plant is easily hindered. When the PH value is between 6.5 и 7.5, the plant can absorb and utilize nutrients in soil with maximum efficiency. So the PH value of organic fertilizer you produce also cannot exceed this range. Здесь, our vertical organic fermenter will be your excellent partner. After fermentation by it, the PH value of organic material generally is 6-8. It can fully meet your needs.

C-N ratio

According to investigation, controlling the carbon-nitrogen ratio of the raw material to 25-30% is the key to improving compost effect. And the produced organic fertilizer can supply sufficient nutrients to the growth of crops. В этом аспекте, there are two tips for you.

- When you process organic fertilizer raw materials with a high C-N ratio. You can choose to add an appropriate amount of nitrogen fertilizer for regulation. Such as urea, и т. д..

- If you use materials of low C-N ratio to make organic fertilizer. Например, куриный помет, свиной навоз, и т. д.. You can mix them with high C-N ratio materials to improve the C-N ratio. Such as straw and corn stalks.

Vertical fermentation pot is suitable for processing all the material above. Используя его, you can get the materials with a C-N ratio of 25-30% easily and quickly.

Вершина 4 Differences between fermentation tank and compost turner

Besides fertilizer fermentation tank, there are also various переворачиватель компоста. They can both be used for organic fertilizer composting. But there are some differences between them. You can choose according to your needs.

Меньше занимаемого места

If you have enough space for organic fertilizer composting, we recommend you to choose commercial compost turner. The machines can fully meet your requirements of both small and large scale composting, high automation and mobile moving, и т. д.. But if your fertilizer plant is limited, our organic fermentation pot will be your ideal choice. Only an area of 10-30㎡, it can help you finish fertilizer fermentation.

Метод компостирования

Composting organic fertilizer in trench and on the disclosed ground are 2 common composting methods in fertilizer suppliers. В это время, composting turner is your best option. including ворошитель компоста с пазом и ворошитель компоста. But if you want to prepare organic fertilizer by in-vessel fermentation method for less pollution. We recommend you to use vertical fermentation pot. It makes fermentation in a closed environment. So there is no smelly odor during fertilizer compost. Кроме того, it is equipped with water spray tower and activated carbon box. They can absorb NH3, H2S and other harmful gases produced by fermentation. It is the perfect solution to secondary pollution.

All year round fertilizer fermentation

If you need a fertilizer composter that decompose organic manure all year round, we commend you to choose fermentation tank. It starts fertilizer composting in a sealed space and uses polyurethane as an temperature insulation layer. This makes your organic fertilizer production less affected by the outside world. Поэтому, you can process compost fertilizer fast without outside world influence, even in cold winter.

Расходы

They are also different at price. В целом, the cost of fermentation pot is more than fertilizer compost turner. If you have a high budget, fermentation tank is your optimal choice. Its price is ranging from $30,000 к $100,000. But if your budget for fertilizer compost equipment purchasing is limited, fertilizer compost turner is an better choice. Both moving type compost machine and groove type compostor are excellent options.

What you need to do before composting organic waste by vertical fermentation tank?

Adequate preparation is the prerequisite for the successful production of high-quality organic fertilizer. Перед компостированием, there are two aspects you need to pay attention to.

Control materials water content at 50-60%

In essence, fertilizer composting is a process of utilizing the activity of microorganisms to decompose organic matter in organic waste. Then organic waste will convert to suitable raw materials for производство органических удобрений. But microorganisms need to continuously absorb water from the surrounding environment to maintain normal metabolism. So keeping water content at an appropriate level is important. 50%-60% is the optimal moisture content for organic waste fermentation. If your materials have higher water content. You can useобезвоживающая машина or add straw, опилки, edible mushroom chaff, etc to decrease it. But if it is lower, you can mix it with fresh manure, which has high moisture content.

Using finer raw materials

The finer of organic raw material, the better of the fertilizer fermentation effect. Because the finer the organic raw material is, the better it will be in contact with oxygen. Здесь, our fertilizer crushing machine can help you a lot. After finishing preparation tasks, your first step to start manufacturing organic fertilizer is composting. Для этого, vertical fermentation equipment from YUSHUNXIN machinery is an ideal choice for you.