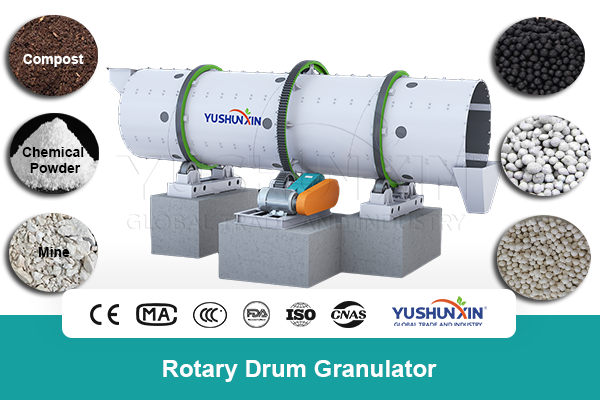

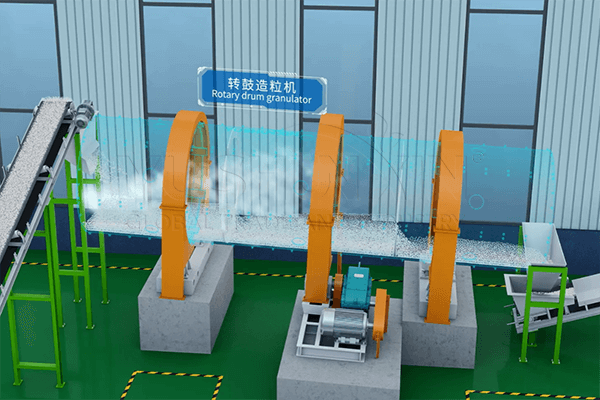

Rotary drum granulator is a fertilizer machine that can make powder material to a rounded particles. This is one of the key equipment in fertilizer making. It has the characteristics of large capacity of 1-30 Т/Ч, 3-6 mm pellets making, automatic operation, ideal erosion resistance, и т. д.. This product is suitable for cold and hot granulation and the large-scale production of complex fertilizers in high and low concentration. More and more industrial fertilizer manufacturers prefer to use it to produce fertilizer granules.

Основные параметры

- Емкость: 1-30 т/ч

- Размер гранул: 3-6 мм

- Скорость грануляции: над 90%

- Feeding material moisture: 20-40%

- Feeding material size: 50 meshes

- Материал оборудования: Carbon steel Q235, rubber lining

- Приложение: навоз животных, остаток биогаза, humus, НПК, бентонит, минеральные отходы, и т. д.

What kind of fertilizer pellets can rotary drum granulator machine produce?

If you plan to start the industrial fertilizer pellet making for commercial purpose, the rotary drum granulator is an ideal choice. It can fully meet your various requirements for industrial granular fertilizer manufacturing. Такой как,

1-30 TPH granular fertilizer making

Whether you start a fertilizer granulation plant in a small or large scale, the drum pelletizer can fully meet your requirements. Потому что, the equipment is capable of producing fertilizer pellets at an output rate ranging from 1 к 30 тонн в час (ТПХ), с 5 models.

3-6 mm size fertilizer granulation

Кроме того, for final size of fertilizer pellets making, the rotary granulation machine can offer you particles of 3-6 мм. This is ideal for both agricultural and industrial applications. How to regulate the particle size from the drum granulation? Only by adjustment of moisture and drum rotation speed.

Round ball fertilizer pelleting

Затем, the rotary drum granulator will prepare uniform, round fertilizer pellets for you. This has a that better performance in mechanical spreading in a large scale, and longer storage, slower release, и т. д.. Так, your fertilizer making business is more competitive in commercial market.

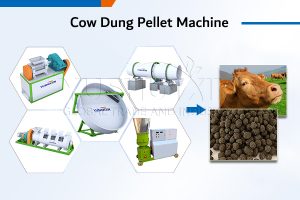

Organic and compound fertilizer production

As for feeding materials, you can freely choose organic waste, agricultural waste and chemical powder. А именно, the drum granulation equipment can granulate powder of cow dung, куриный помет, biogas making waste, солома, рисовая шелуха, НПК, бентонит, минеральные отходы, и т. д.. Поэтому, it is an key equipment for both industrial organic fertilizers granulation и compound fertilizer pellets manufacturing.

Technology parameters of rotary drum granulator

| Модель | Власть (кВт) | Diameter (мм) | Length (мм) | Installation Angle | Rotary Speed (r/min) | Емкость (т/ч) |

|---|---|---|---|---|---|---|

| SXZGZ-1240 | 5.5 | 1200 | 4000 | 2-5° | 17 | 1-3 |

| SXZGZ-1560 | 11 | 1500 | 6000 | 2-5° | 17.5 | 3-5 |

| SXZGZ-1870 | 15 | 1800 | 7000 | 2-5° | 11.5 | 5-8 |

| SXZGZ-2080 | 18.5 | 2000 | 8000 | 2-5° | 11 | 8-15 |

| SXZGZ-3210 | 37 | 3200 | 10000 | 2-5° | 9.5 | 15-30 |

Learn more about fertilizer rotary drum granulator now!

How much does a rotary granulation equipment cost?

The cost of rotary granulation equipment varies widely depending on production capacity, material configuration, and automation level. В общем, the price ranges from $8,000 к $90,000, making it accessible for both small and large fertilizer plants. You can choose the best one according to your budget.

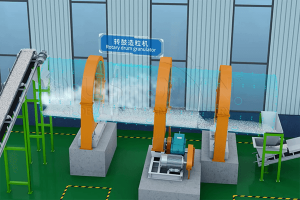

How does a drum granulator work for fertilizer pellet production?

В общем, the rotary drum granulation machine working process is closed related to the design and granulation method employment. This is a wet granulation fertilizer equipment, which mainly makes use of liquid cohesion to facilitate the granulation of powder. Также, the drum rotation plays an important role. Поэтому, this process contains the following 3 шаги:

- Первый, the belt conveyor send the powder materials to the drum.

- Затем, through a certain amount of liquid, the power material will has excellent cohesion after being wet in the drum body.

- Следующий, the main motor drives the shaft mesh with the large gear ring, which is key for drum rotation.

- Under the action of drum rotation, the wet powder material will combine with each other and roll into required fertilizer pellets.

Learn more about the rotary drum granulator!

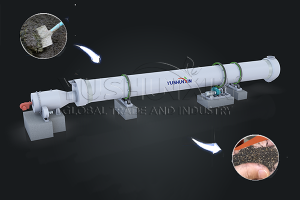

Is there automatic liquid spray device for rotary drum granulator machine?

Конечно. YUSHUNXIN can offer you customized rotary drum granulation machine with automatic liquid spray machine.

It crosses the rotary drum to atomize water, liquid binders, or even concentrated solutions directly. This controlled addition of liquid increases the surface adhesion of particles, which accelerates seed formation and growth into uniform fertilizer granules.

By adjusting spray pressure, droplet size, and position, you can control the material moisture in the drum pellet making process. Так, you can control the granular fertilizer size you produce freely.

Can rotary drum pelletizer operation with fertilizer steam granulation?

В общем, для 1-10 TPH fertilizer pellet making, экономично использовать метод холодной грануляции. Which relies on the material moisture and drum rotation to granulte the powder fertilizer, как упоминалось выше. It is a simple process with low energy consumption.

Однако, if you want to start a large scale production of fertilizer in 10-30 T/H faster, inject the steam into the rotating cylinder is an ideal choice. This hot granulation of fertilizer raises the temperature and moisture of materials. Поэтому, порошкообразное удобрение мягче и его легче агломерировать, которые превращают материалы в более круглые и прочные гранулы удобрений..

Кроме того, there are both professional steam inject boiler for drum granulation of fertilizer. Like the liquid spray system, it can help you control the adding of hot granulation steam precisely.

Вершина 2 rotary drum granulator designs to reduce erosion in fertilizer pellet making

When producing commercial fertilizer pellets in a large scale, equipment durability is one of the biggest concerns. How about the rotary drum granulator machine? Здесь, YUSHUNXIN developed the drum pelletizer with innovative designs to reduce erosion. Такой как,

Dual layer drum body design

The first is the dual layer design of the drum body. Обычно, the outer shell of the rotary granulation machine is made from Q235 carbon steel, which provides high mechanical strength and durability. Inside, a rubber lining acts as a buffer against chemical erosion and mechanical impact from continuous material movement. As a result, you will benefit from longer equipment lifespan and fewer maintenance interruptions.

Granulation sticking knocker holes

The second design feature is the use of granulation sticking knocker holes. Because of powder granule making with liquid, some sticky materials may adhere to the drum wall. This will leads to uneven granules and accelerates surface damage. Так, we especially design the rotary pellet machine with knocker holes. This mechanical devices can help you dislodge the buildup, keeping the inner surface clean and reducing wear.

What is the layout of organic and compound fertilizer production plants with rotary pelleting machine?

Для этого, you can choose to using the rotary drum granulator machine only, or combine with other equipment to setup a drum granulation line. With batching machine, compost equipment, миксер, дробилка, сушилка, cooler and other auxiliary equipment, you can produce quality compound and organic fertilizer for self use or commercial sale. There are customized drum fertilizer pellet plant layout for you.

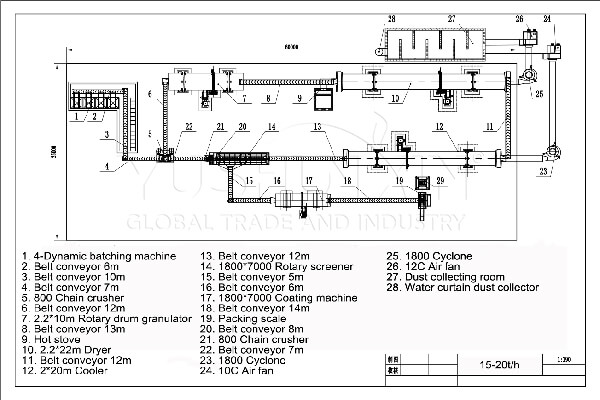

100,000 tons/year compound fertilizer production line with rotary drum granulator machine

When you plan to setup a 100,000 tons/year compound fertilizer production plant, a SXZGZ-3210 drum pelleting equipment is the best choice. It can granulate complex powder of 15-30 тонн в час. Combing with dynamic batching machine, 22m dryer, 20m cooler, 1800*1700 granule screener, 800 chain crusher, 1800*1700 человек, наносящий покрытия, double bucket packing equipment and other accessories. Таким образом, you can make complex fertilizer from powder mixture of urea, хлорид аммония, сульфат аммония, моноаммонийфосфат (КАРТА), диаммонийфосфат (ДАП), хлорид калия (СС), сульфат калия (СОП), и т. д..

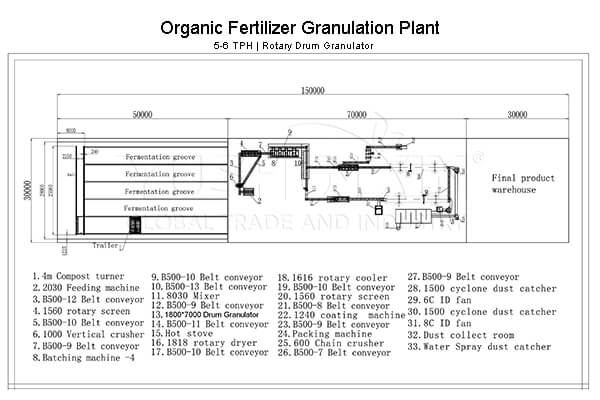

30,000 tons/years organic fertilizer production line with drum granulating equipment

Когда дело доходит до 30,000 tons annual organic fertilizer granule making, the SXZGZ-1870 is advisable equipment. Кроме того, you need to configuration it with 8030 миксер, 1818 ротационная сушилка, 1616 круче, 1560 sieving equipment, 1240 машина для нанесения покрытий, 600 chain crusher, and single bucket bagging scale. Кроме, because organic fertilizer granule making from composted industrial residue, сельскохозяйственные отходы, навоз животных, и т. д., which has high moisture and sticking together, you need to treat organic waste by compost machine, crusher and powder screening before granule manufacturing.

Except the two production lines, we also provide other lines with different capacity, такой как 20,000 t/y or 50,000 t/y, complete sets of equipment for organic or compound fertilizer production can procure from us. If you need rotary drum granulators or other fertilizer machines, вы можете связаться с нами для получения подробной информации.

Кроме того, there are many other линии по производству удобрений and machines for your choice. Такой как дисковый гранулятор with economical price, гранулятор органических удобрений нового типа for hard fertilizer pelleting, двойной роликовый пресс for dry powder granulation, и т. д.. Welcome to contact us for details.