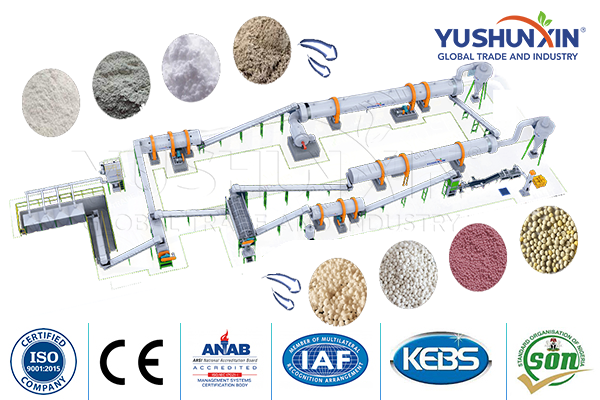

Линия по производству комплексных удобрений, как следует из названия, это производственная линия, широко используемая при производстве химических удобрений., как следует из названия, это производственная линия, широко используемая при производстве химических удобрений.. Обычно он содержит оборудование для дозирования, сокрушительный, смешивание, грануляция, сушка, охлаждение, покрытие, сумки и аксессуары. Они могут производить сложные удобрения различной концентрации и типа.. Например, производство гранул NPK-комплексных удобрений и производство смешанных NPK-удобрений.. Более того, в соответствии с необходимостью, ЮШУНЬСИНЬ предложим вам индивидуальные решения и машины. Включая план завода по производству гранулированных комплексных удобрений npk blue., Линия по производству фосфоритных удобрений, и т. д..

Основные параметры

- Вместимость: 1-20 т/ч

- Материал оборудования: Углеродистая сталь Q235/сплав

- Напряжение: 220В/380 В/415 В/440 В/480 В(50Гц/60 Гц)

- Форма химического материала: порошок или гранулы

- Типы: Производство NPK-удобрений, производство массовых удобрений, Производство удобрений ССП, и т. д.

- Приложение: Мочевина, хлорид аммония, суперфосфат,хлорид калия, и т. д.

Как производить 15-15-15 Комплексное удобрение NPK?

Какое сырье используется при производстве комплексных удобрений??

В общем, для переработки сложных удобрений, ваш основной материал должен содержать два или более питательных элемента в виде азота., фосфор и калий. Затем, какой материал содержит эти элементы? Есть некоторые для справки.

Азот в основном отвечает за содействие росту ветвей и листьев. Потому что это может улучшить способность растений усваивать питательные вещества.. Если вы хотите приготовить сложное удобрение с высоким содержанием азота. Вы можете использовать мочевину, хлорид аммония, сульфат аммония, нитрат аммония и нитрат кальция в качестве материалов.

Фосфат играет важную роль в цветении и плодоношении. Если вы хотите увеличить его содержание при приготовлении комплексного удобрения. Моноаммонийфосфат(КАРТА), диаммонийфосфат (ДАП), тройной суперфосфат (ТСП) и суперфосфат (ССП) отличные варианты для вас.

Калий необходим для содействия развитию корневищ. И улучшение способности сельскохозяйственных культур адаптироваться к изменениям температуры и противостоять вредителям и болезням.. Затем хлорид калия (СС), сульфат калия (СОП), карбонат калия и зола растений – залог производства комплексных удобрений с калием.

Существуют различные материалы для изготовления сложных удобрений. Вы можете выбрать в соответствии с вашими потребностями. Как сложные процессы производства удобрений. Для разных процессов, вам нужно подготовить материалы разной формы. Порошок или гранулы?

2 самые продаваемые линии по производству сложных удобрений в ЮШУНЬСИНЕ

Для удовлетворения потребностей производства сложных удобрений, наши инженеры разрабатывают различные системы производства химических удобрений. Среди них, следующее 2 Виды линий по производству сложных удобрений - наша популярная продукция. Они предназначены для высокодоходного бизнеса по производству сложных удобрений и установки завода по производству комплексных удобрений с быстрой окупаемостью соответственно.. Для материалов, один использует порошок, а другой - гранулы.

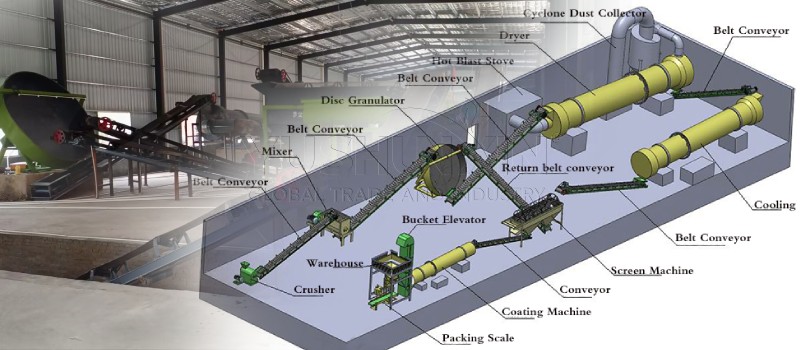

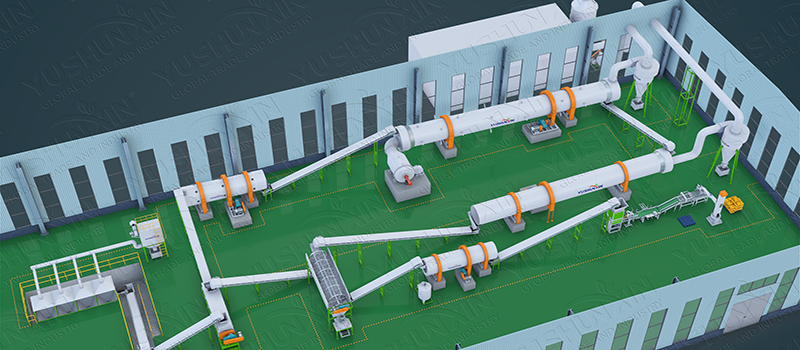

Линия грануляции NPK-удобрений на продажу

Если вы склонны вносить гранулированные комплексные удобрения, мы будем рекомендовать Линия по производству удобрений NPK тебе. Поскольку описанный выше процесс, он будет производить для вас гранулы комплексных удобрений NPK из порошка.. Кроме того, мы можем предложить вам индивидуальный план приготовления комплексных удобрений в соответствии с вашими потребностями., как емкость.

- Когда вы планируете сделать 1-6 тонн гранул химических удобрений в час, тот линия по производству дисковых пеллет это лучший выбор. Экономичная цена и выше 93% скорость грануляции.

- Но если вы хотите увеличить масштаб завода по производству комплексных удобрений, можно заменить тарельчатый гранулятор на гранулятор с вращающимся барабаном, который имеет большую производительность 1-30 т/ч. Таким образом, он может полностью удовлетворить ваши потребности, планируете ли вы построить небольшой, средний или крупный завод по производству комплексных удобрений.

Запросить линию гранулирования комплексных удобрений NPK!

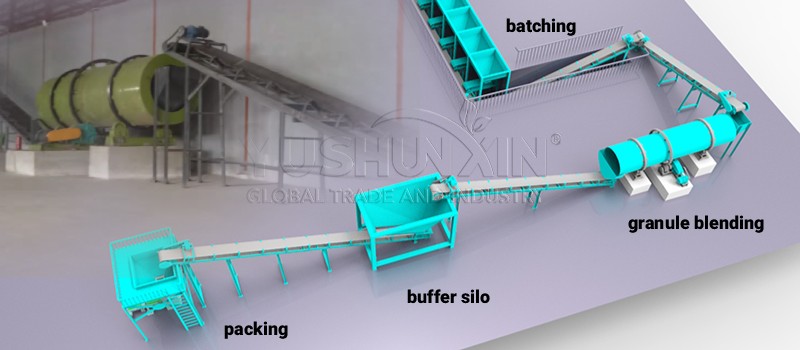

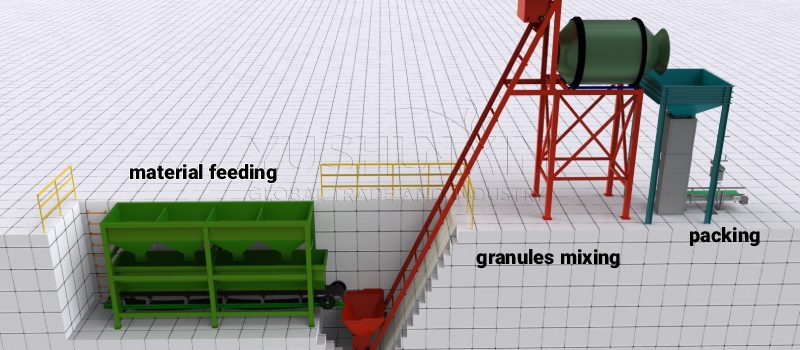

Продается линия по производству удобрений BB

Если вы планируете производить гранулированное комплексное удобрение, но твоего бюджета недостаточно. Вы можете выбрать это Линия по производству удобрений BB, которая также известна как линия по производству удобрений для массового смешивания. Вам просто нужно подать несколько отдельных удобрений или комплексных удобрений в дозирующие бункеры.. Затем миксером равномерно перемешайте их., вы можете упаковать удобрения. Есть только механическая сила, но химическая реакция не происходит. Таким образом, линия по производству удобрений для массового смешивания имеет меньше технологических этапов и значительно снижает ваши производственные затраты.. Он состоит из четырех видов оборудования для внесения удобрений.. Включая дозировочную машину, конвейер, смеситель и упаковочная машина. Вам нужно только подготовиться $10,000-$90,000 бюджет на производство NPK-удобрений в 1-20 Производительность Т/Ч.

Получите линию по производству удобрений BB прямо сейчас!

Как превратить сырье в необходимое вам комплексное удобрение?

Если вы хотите превратить сырье в высококачественное удобрение, вам нужно обработать его несколько раз. Как профессиональный производитель оборудования для внесения удобрений, Shunxin может предоставить вам подходящее оборудование для внесения удобрений для каждой процедуры.. Ниже приводится наиболее полная процедура производства сложных удобрений..

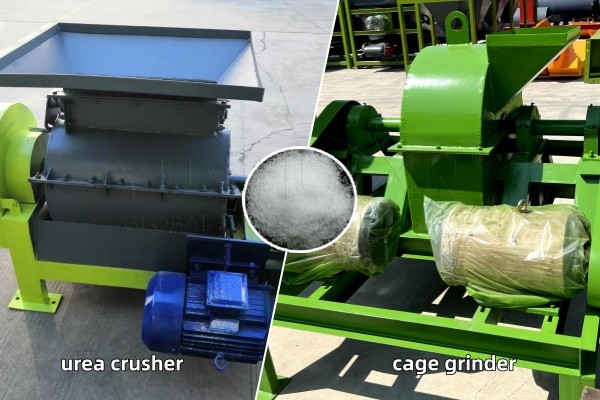

Дробление

Прежде чем производить сложные удобрения, вам нужно превратить все материалы в порошок. Потому что это удобно для последующего дозирования и смешивания.. Итак, дробилка удобрений играет важную роль в производстве высококачественных химических удобрений.. Клетчатый измельчитель и цепная дробилка подходят для измельчения сложных удобрений..

Пакетирование

Комплексные удобрения специально производятся для восполнения питательных веществ, которых не хватает при росте растений.. Поэтому вам нужно сделать это в определенной пропорции.. Пакетирование – это процесс корректировки пропорции. Во время этого процесса, есть статика дозирующая машина и динамическое автоматическое дозирующее оборудование на ваш выбор. Они имеют высокую степень автоматизации и могут значительно сэкономить ваше время и производственные затраты..

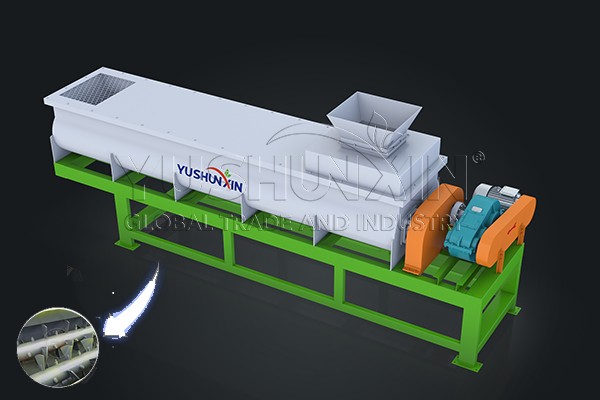

Смешивание

Затем нужно полностью перемешать материалы. Это ключевой шаг к созданию однородного комплексного удобрения.. Для этого, мы рекомендуем вам выбрать горизонтальный миксер или дисковый миксер. Первое может помочь вам равномерно эффективно смешивать различные химические материалы, а второе может помочь вам снизить затраты на производство комплексных удобрений..

Гранулирование

Если вы хотите еще больше улучшить сложные удобрения, превратить его в гранулы — отличный выбор. После гранулирования, площадь контакта между удобрениями станет меньше, из-за чего его нелегко приклеить. Поэтому удобно хранить и транспортировать.. Среди наших грануляторы химических удобрений, лотковый гранулятор, гранулятор с вращающимся барабаном больше подходит для использования метод влажной грануляции. И двухвалковая грануляция это идеальный выбор, если вы хотите использовать метод сухой грануляции.

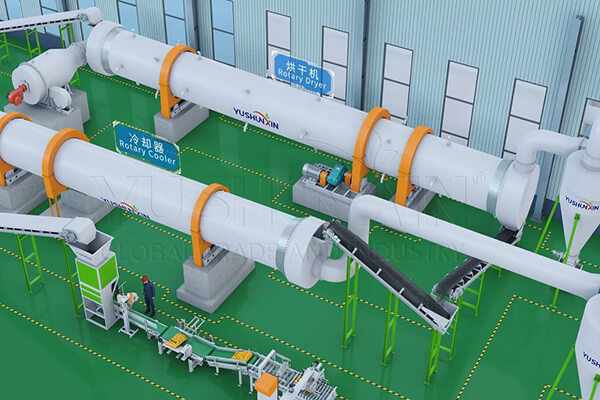

Сушка и охлаждение

Чрезмерное содержание влаги не способствует хранению и использованию удобрений.. Если влажность удобрения превышает 14%, тот процесс сушки неизбежно. Затем после высыхания, охлаждение может удалить воду с поверхности гранул, и снизить температуру.

Скрининг

Во время этого процесса, вам нужно различать квалифицированные и неквалифицированные удобрения.. Затем передайте квалифицированное удобрение для следующей процедуры., и неквалифицированные для повторного гранулирования. Ротационная просеивающая машина может помочь вам выполнить задачу на отлично.

Покрытие

Образует защитную пленку на поверхности химического удобрения.. Защитная пленка может изолировать воздух, благодаря чему гранулы снова станут легко прилипать. Если вы хотите добавить защитную пленку к своим химическим гранулам, вы можете купить наш барабанное оборудование для нанесения покрытий.

Упаковка

Упаковка это последняя процедура всей линии по производству комплексных удобрений.. Это необязательно, если вы производите удобрения для собственных нужд.. Но если вы хотите продать его другим, это может повысить конкурентоспособность ваших удобрений.

Как начать бизнес по производству сложных удобрений?

Спрос на комплексные удобрения растет, все больше и больше людей или компаний переходят на производство химических удобрений. Знаете ли вы, что нужно учитывать, если вы хотите начать бизнес по производству сложных удобрений?? Есть несколько советов для справки:

Составьте бюджетный план производства комплексных удобрений

Он основан на вашем опросе и исследованиях в отрасли сложных удобрений.. Этот план должен включать ваш общий бюджет., а также ваш бюджет для каждого проекта. Например, заводская земля, оборудование для удобрений, материалы, и т. д.

Решите свой химический материалы и найти стабильного поставщика

Только после определения вида сырья, Вы можете выбрать подходящее оборудование. Со стабильным источником сырья, вы можете производить удобрения стабильно. Это гарантирует, что у вас будет достаточно продуктов для продажи..

Выбираем место для строительства цеха завода сложных удобрений

Оно должно находиться вдали от места проживания и работы населения.. Потому что в процессе производства сложных удобрений будет некоторое загрязнение.. Вам необходимо не допустить, чтобы это загрязнение повлияло на жизнь жителей.. А мастерскую нужно расположить в легкодоступном месте.. Выгодно при продаже и транспортировке сложных удобрений..

Выберите надежного производителя оборудования для комплексного внесения удобрений

Он может не только предоставить вам высококачественное оборудование для комбинированных удобрений., но также дам вам много полезных советов. SX имеет 20 многолетний опыт производства оборудования для сложных удобрений. Это оптимальный выбор для вас.

Другие статьи о производстве комплексных удобрений

Кроме того, если вы хотите узнать больше о производство органических удобрений, мы также можем предложить вам лучшие решения. Добро пожаловать, свяжитесь с нами, чтобы начать свой комплекс & Успешный бизнес по производству органических удобрений.