With the development of agriculture in Australia, more and more companies expand their business to the fertilizer manufacturing. Especially those whose products can be used as fertilizer material. When they want to make fertilizer from their products, معدات الأسمدة المهنية can help them a lot. On 2nd September 2022, a company, which is committed to environmental remediation technology, inquired about how to prepare compound fertilizer out of super phosphate and its proprietary dry powder reagent? Then after discussing the details of his requirements, we sent him a 2t/h double roller granulation line for خط تصنيع الاسمدة المركبة. فيما يلي تفاصيل الاتصال المحددة في هذه الحالة:

نظرة عامة على المشروع

- دولة: Brisbane, Australia

- سعة: 1-2 ذ

- مادة: سوبر فوسفات, proprietary dry powder reagent

- متطلبات: Compound fertilizer granules making

- حل: خط التحبيب الصحافة الأسطوانة

Are there any requirements for powder raw material?

كما ذكر أعلاه, this customer from Australia wanted to make compound fertilizer from super phosphate and its proprietary dry powder reagent. So he asked us are there any requirements for powder raw material? Is this powder reagent suitable for complex fertilizer production?

What kind of materials suitable for phosphate-based compound fertilizer making?

SX fertilizer processing machines are made of anti-corrosion, wear-resistant steel. So they have high adaptability and are suitable for many kinds of chemical materials processing. لكن, there are two items you need to focus on when choosing materials for your manufacturing of compound fertilizer.

- لشيء واحد, it is absolutely not allowed to use harmful materials or materials that will produce harmful substances after mixing together.

- لآخر, you need to select materials according to your needs. ل صنع الأسمدة SSP, you also need to buy sulfuric acid or nitric acid. لكن, if you plan to produce phosphate-based NPK compound fertilizer, you also need to add materials that contains rich nitrogen and Potassium. Such as urea and ammonium sulfate can provide nitrogen for your complex fertilizer making. Potassium chloride (ممسحة) and potassium sulfate (إجراءات التشغيل القياسية) contain rich potassium nutrients.

Is this powder reagent suitable for complex fertilizer production?

For this Australian client, super phosphate is a source of phosphate elements in compound fertilizer. علاوة على ذلك, the powder reagent has the ability to reduce heavy metals and other pollutants in soils, water and industrial solids and sludges. If using it in soil, it can neutralize acid, trap trace metals and prevent leaching, whilst enhance nutrient retention capacity and promote vigorous plant growth. لذلك, it is an ideal choice to improve compound fertilizer quality.

Which granulator is suitable for your compound fertilizer production?

The customer from Australia planned to turn his powdery materials into granular compound fertilizer for commercial purpose. And the phosphate-based compound fertilizer pellet output is 1-2 ذ. لهذا, ال خط التحبيب الأسطوانة المزدوجة هو الخيار الافضل.

1-2 tons complex fertilizer pellets making output

In terms of capacity, roller granulator is an ideal choice for small scale chemical fertilizer granule production. على العموم, it has 3 models – SXDJ-1T, SXDJ-1.5T and SXDJ-2T. Their output of phosphate-based compound fertilizer pellets are 1 ذ, 1.5 t/h and 2t/h respectively.

| نموذج | قوة (كيلووات) | Granule Diameter (مم) | حجم ورقة الأسطوانة (مم) | أبعاد (مم) |

|---|---|---|---|---|

| SXDG-1T | 15 | 3-10 | 150×220 | 1450×800×1450 |

| SXDG-1.5 T | 18.5 | 3-10 | 150×300 | 1450×850×1500 |

| SXDG-2T | 22 | 3-10 | 185×300 | 1630×850×1650 |

97% Granulation rate of phosphate-based powder

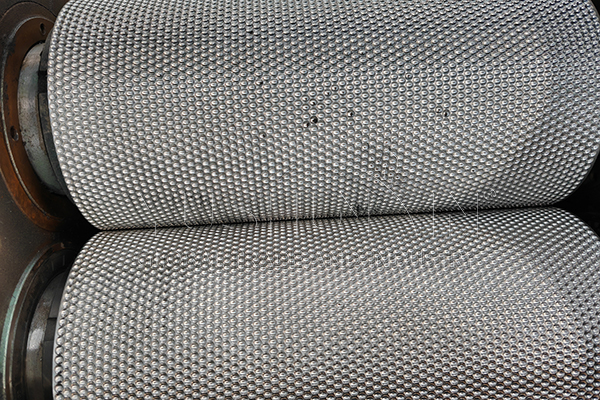

علاوة على ذلك, ال 97% high granulation rate of most chemical powder is also an highlight that attract fertilizer mamufacturers. من ناحية, the ball sockets on rollers has same size, which is key to press phosphate powder mixture into fertilizer pellets. على الجانب الآخر, there is stirring teeth and screen under the rollers to generate granuar complex fertilizer without sticking.

Low Cost for complex fertilizer pellets production

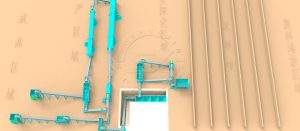

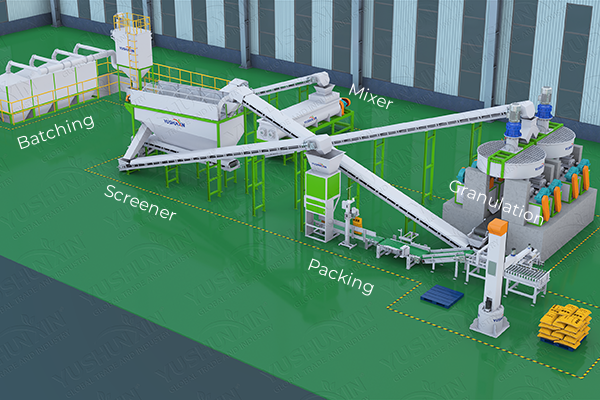

Because the double roller extrusion machine mainly adopts طريقة التحبيب بالبثق الجاف, which makes fertilizer preparation process nearly without water. So it doesn’t need to spend money on drying and cooling. General, the roller press granulation line for 1- 2 T/H phosphate-based compound fertilizer manufacturng needs 6 آلات. بما في ذلك آلة الخلط, SXNS-40 urea crusher, خلاط رمح مزدوج, SXDJ-2T roller granulator, SXGS-1030 screener and packing equipment.

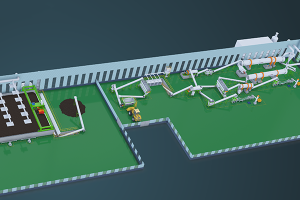

Is there this fertilizer making line in Australia you can visit?

If you want to know how the whole double roller granulation line works to produce compound fertilizer, we can send you related pictures and videos. They were all filmed on site in our equipment manufacturing factory or customers’ fertilizer making workshops. And if you want to further test it, you can come to our factory for on-site inspection. Our fertilizer equipment manufacturing factory is located in Chengguan Township, مدينة شينغيانغ, مدينة تشنغتشو, مقاطعة خنان, الصين.

The above are details about our communication with the customer from the Australia. فضلاً عن ذلك, خط التحبيب الأسطوانة المزدوجة, we also can provide you with solutions for compoud fertilizer production. هم economical disc pelleting system, خطة التحبيب طبل دوارة with large capacity and high erosion resistance, إلخ. إذا كنت مهتما بهم, يرجى الاتصال بنا على الفور.