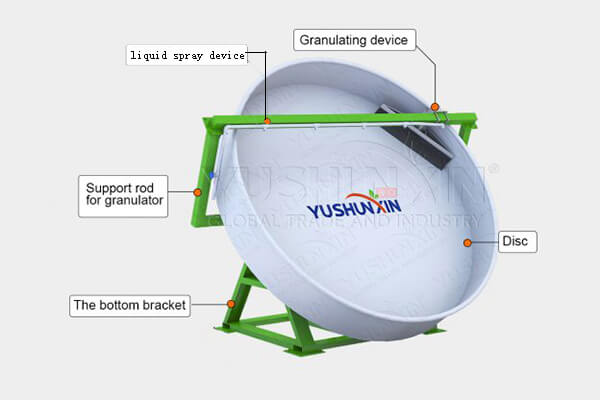

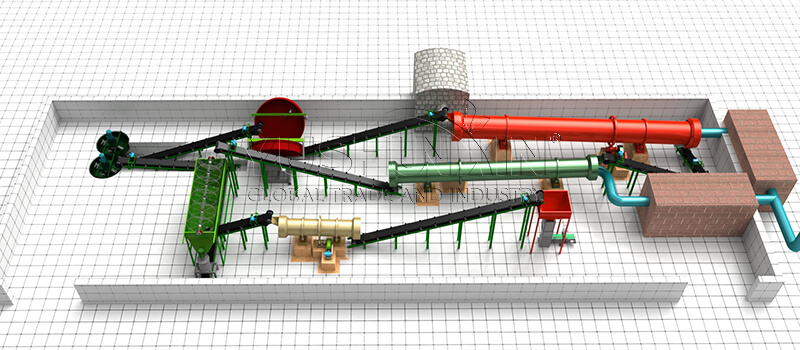

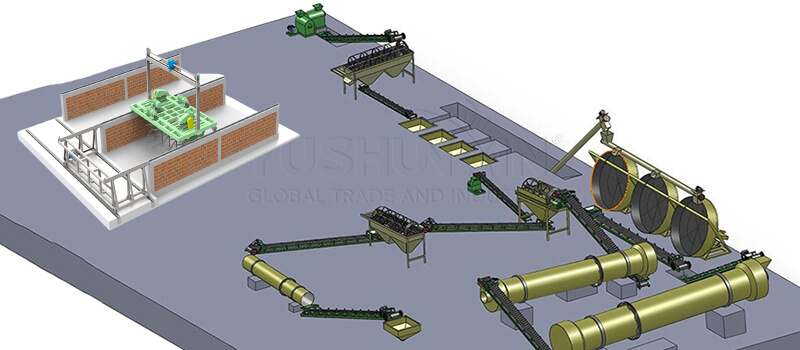

In the process of fertilizer manufacturing, the disc granulator machine is one of the key equipment to process powder fertilizer into granules. Because wet granulation method adoption and compact design, it has characteristics of high granulation rate, low investment, wide granule size, dll.. Selain itu, combining with corresponding fertilizer equipment, such as compostor, pengaduk, penghancur, pengering, cooler and so on. You can create a disc granulation line to help you produce higher quality fertilizer pellets, whether it is organic or compound.

Parameter Utama

- Kapasitas: 1-6 th

- Ukuran Butiran: 1-8 mm

- Tingkat granulasi: lebih 93%

- Memberi makan kelembaban bahan: 20-40%

- Ukuran bahan pakan: 50 jerat

- Bahan Peralatan: Baja karbon Q235, Paduan

- Aplikasi: kotoran hewan, residu biogas, humus, NPK, Bentonite, mineral waste, dll.

How a pan granulator works to make fertilizer into granules?

When it comes to the working principle, it contains 2 parts. Wet granulation method and the disc rotation. The former makes us of liquid cohesion to facilitate fertilizer powder granulation. While the latter generate centrifugal force, which make powder roll together and form into pellets. The whole process is as follows:

- Pertama, the processed powder materials will be transported into the disk and added with some water.

- After the pan granulator is set in motion, the disc will be driven by transmission devices.

- Then the fertilizer materials will move upward under the action of the rotation of the disc, and fall due to gravity.

- Dalam proses ini, the powder fertilizer will roll and stick to each other and finally formed into round fertilizer granules.

- After reaching the predetermined diameter, the granulated fertilizer will be out of the pan to the next procedure.

Why so many manufacturers buy a pan pelletizer for their fertilizer granulation plants?

Pan pelletizer is a hot selling fertilizer making machine in YUSHUNXIN. From the feedback of our customers, ada 5 reasons as follows:

Inquiry the pan pelletizer for your fertilizer making now!

How do you control the granules size in pan pelletizer granulation?

Umumnya, fertilizer production suppliers also have different requirements in granules size. And they may want to change the size of their fertilizer pellets in the future. So how to regulate the particle size with disc granulator machine? Biasanya, there are two ways to regulate the granules size.

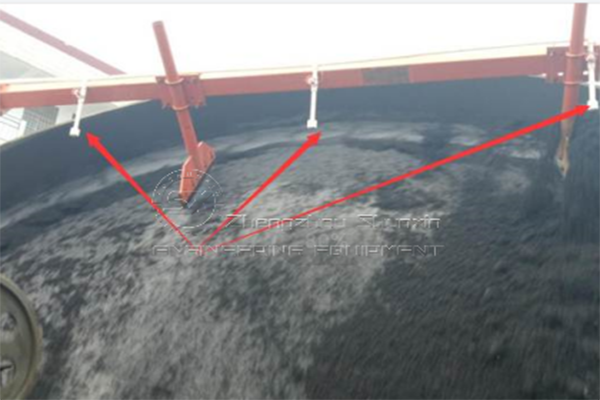

Changing moisture content

Pertama, you can change the pellet size by controlling the water content, and the water spray system can help you control the raw material moisture easily. Lebih sedikit air, ukuran lebih kecil; banyak air, ukuran lebih besar.

Adjusting disc angle

And another solution to this problem is regulating the pan slope angle. You can adjust the angle between 35 degrees and 55 degrees to regulate the final granules size. Kemiringan yang tajam, ukuran lebih kecil; kemiringan lambat, ukuran lebih besar. Dengan cara ini, you can produce particles of the diameter you need within 1-8mm.

Learn more about the pan pelletizer immediately!

Which type of disk pelletizers is suitable for your fertilizer pellet making?

It is common that different customers have different needs and requirements in production. As a professional and considerate supplier, we design various types of disk pelletizers for you. Whether you have a small, medium or large fertilizer production line, whether you want to produce organic or compound fertilizers, they can meet your needs.

Among them, SXYZ-1800 is the one with the smallest output, tentang 0.8-1.2 tons/h. It is an ideal choice for you, if you want to start a small scale fertilizer making. The largest output one is SXYZ-3600, tentang 4-6 tons/h, it is suitable for the medium scale fertilizer production line. If you need larger scale production, you can increase the number of pan granulators to expand the output. Selain itu, they can both be used in producing organic fertilizers or compound fertilizers.

Details technology parameters of pan granulation machine:

| Model | Diameter (mm) | Edge Height (mm) | Rotary peed (r/min) | Motor Power (kw) | Kapasitas (th) | Model of Reducer (KW) | Ukuran (mm) |

|---|---|---|---|---|---|---|---|

| SXYZ-1800 | 1800 | 300 | 21 | 3 | 0.8-1.2 | XWD5-71-3 | 2060*1700*2130 |

| SXYZ-2000 | 2000 | 350 | 21 | 4 | 1.2-1.5 | XWD5-71-4 | 2260*1650*2250 |

| SXYZ-2500 | 2500 | 450 | 14 | 7.5 | 1.5-2.0 | ZQ350 | 2900*2000*2750 |

| SXYZ-2800 | 2800 | 450 | 14 | 11 | 2.0-3.0 | ZQ350 | 3200*2200*3000 |

| SXYZ-3000 | 3000 | 450 | 14 | 11 | 2.0-4.0 | ZQ350 | 3400*2400*3100 |

| SXYZ-3600 | 3600 | 450 | 13 | 18.5 | 4.0-6.0 | ZQ350 | 4100*2900*3800 |

Get the your customized disc granulation machine!

How much does disc pellet machine cost?

Akhirnya, the price of disc granulator machine is an item most customers pay attention to. And it is a major factor in determining whether customers are willing to buy this fertilizer granulation machine. Di Sini, you can buy disk granulation machine from YUHSUNXIN at a factory price. 3,000 dollars/set to 16,000 dollars/set in 2025. Umumnya, the disc granulator price is closed to related to the capacity.

- A small-scale disc pelletizers designed for laboratory use or small farms may start from around $3,000 to $4,500. These compact machines are suitable for processing small batches of organic fertilizer or other powdery materials di dalam 0.5-1.5 ton per jam.

- Untuk 1.5-3 TPH models commonly used in commercial fertilizer plants, the price typically ranges between $4,400 Dan $10,000. These machines usually have a larger disc diameter, adjustable inclination angles, and automated feeding systems, making them more efficient and suitable for continuous production.

- Large-scale disc pellet machines designed for industrial fertilizer production lines can cost anywhere from $10,000 to over $16,000. These machines feature higher output capacities of 3-6 th, durable materials, and advanced control systems to ensure uniform pellet size and density.

It is important to note that the machine price is not the only cost factor. Buyers should also consider related expenses such as installation, transportation, and maintenance. Selain itu, customization options like anti-corrosion lining or automatic spraying devices may increase the investment of pan granulation machine purchasing. If you want to know detail price of disc pelletizer you need, you can contact us.

Inquiry precise quote for disc granulation machine!

Can pan pelletizer be used in large scale fertilizer pellets making?

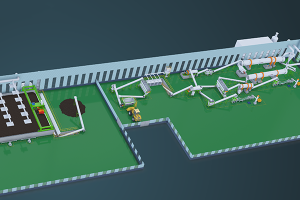

Tentu saja. Umumnya, a pan granulation can process 1-6 tons of pellets per hour for you. For larger scale organic and chemical fertilizer production, you can increase the number of disc granulation machines. Especially when you setup a industrial disc fertilizer granulation line. Combining with corresponding equipment of composting, crushing mixing, pengeringan, pendinginan, packing, dll., you can finish large scale organic or compound fertilizer manufacturing easily. Misalnya,

Untuk 10 t/h organic fertilizer production line, you can use two sets of SXYZ-3600 pan pelletizers

Or buying a three pan granulation system for your 15 – 20 t/h chemical fertilizer production

Common FAQ about disc granulator

Besides the above information, you may still want to know more about pan pellet equipment. There are some common FAQs about disc granulator we summarize from our past customers’ feedback for your reference.

A: Before disc granulation, you need to make sure the raw material moisture content about 30%. Because in this case, powdery fertilizer materials can combine with each other to form into pellets effectively. Then what is the water content of the fertilizer pellets after pan granulation? Can it be below 10%? It means a low possibility of sticking and easier transport and storage? Umumnya, the fertilizer granule moisture content is about 20% after disc pellet making. But you can use rotary drum dryer to reduce the granule water content to below 10%.

A: Tentu saja. Seperti disebutkan di atas, YUSHUNXIN pan pellet machine usually adopts Q235 carbon steel. Tetapi, in order to fully meet your requirements, there is also disc granulation machine with stainless steel lining to further improve the erosion resistance and prolong the service life. Selain itu, you also can choose customized disk granulator with spray design, power, dll..

A: Both are no problems. Seperti disebutkan di atas, YUSHUNXIN disc granulator machine can granulate not only chicken poop, kotoran sapi, limbah babi, limbah jamur, etc but also N/P/K powder, bentonit, zeolit, dll.. If you are still not sure, you can contact us immediately for an answer.

A: 5-8 minutes. This granule making equipment adopts wet granulation method. Under the help of water, powder material will combine with each other more quickly and effectively. Karena itu, you can finish the turning from powder to pellets within 5-8 minutes. But this is a continuous process instead of batch by batch.

A: About 50 jala. Using this kind of raw material, you can produce fertilizer pellets easier. And with a more beautiful appearance.

Why choose YUSHUXNIN among so many pan granulator manufacturers?

When you have a certain understanding of the disc granulator machine. The next step is to find a reliable company so that you can buy high cost-effective equipment

YUSHUNXIN Engineering Equipment Co.Ltd. is definitely an ideal choice for you. It is the leading brand of fertilizer equipment in China and has nearly 20 years of experience in fertilizer equipment manufacturing. YUSHUNXIN has a professional team comprised of experts, professors and senior engineers and is dedicated to the research, development, manufacture and promotion of organic fertilizer & peralatan pupuk majemuk. What is more important is that our products are complete in specifications and quality, and all indicators far exceed national and international standards. These help us earn trust from domestic and foreign customers.

Lebih-lebih lagi, ada juga granulator drum putar with large capacity, roller extrusion machine for dry powder granulation, mesin pelet pupuk organik tipe baru for hard particle making, etc for you choice. Come to get your customized fertilizer making machine and project solutions immedaitelty.