Organic fertilizer granulator, as name suggests, is designed for turn powdery organic fertilizer into pellets. Mais, for your organic granulating fertilizer plant setup, which equipment is the best? How to buy a suitable pelletizer for your organic fertilizer production? Ici, YUSHUNXIN fertilizer equipment company will be your good partner. There are various granular organic fertilizer making machines for your choice. Whether you plan to produce organic fertilizer granules from wet or dry materials, in a small quantities or large scale, they will fully meet your requirements. De plus, for industrial granular organic fertilizer factories establishing, there are also customized solutions and all sets of equipment for organic fertilizer pelletizing.

Paramètres principaux

- Capacité:1-20 ème

- Taille des granules: 1-10 mm

- Taux de granulation: 90%-97%

- Matériel d'équipement: Acier au carbone Q235, alliage

- Coût: $3,500-$80,000

- Tension: 220v/380v/415v/440v/480v(50Hz/60 Hz)

- Application: bouse de vache, caca de poulet, déchets de porc, fumier de cheval, etc.

How to produce organic fertilizer pellets from wet or dry powder?

To make high-quality organic fertilizer pellets, it’s important to choose the right granulation machin. Pour ça, The moisture of your material is an aspect, you need to consider.

Wet organic fertilizer granulation machine of 20%-40%

When your make organic fertilizer granules from wet materials, de 20%-40% teneur en humidité, le wet granulation equipment est le meilleur choix. It will makes use of the high water content to enhance the cohesion between materials. Donc, you can turn powder compost into granular organic fertilizer faster.

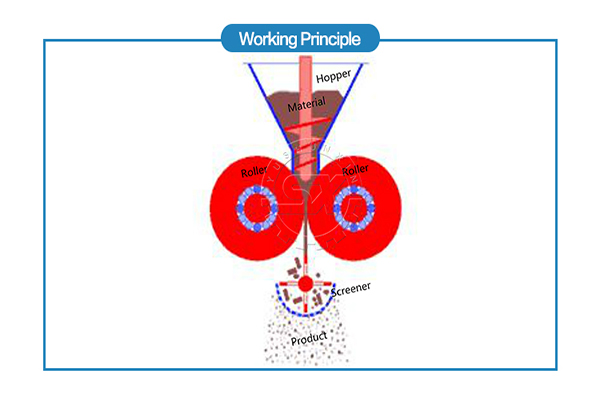

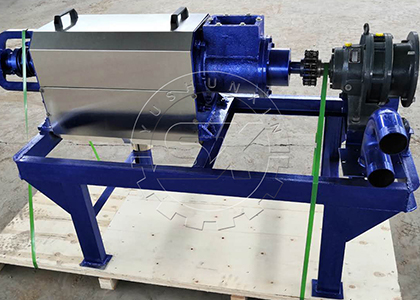

Dry extrusion granulator for 20% moisture material processing

En outre, if you organic material had dried or dewatered, which has a moisture of lower than 20%. Here are also dry organic fertilizer granulator pour toi. Because produce organic fertilizer into pellets by roller press, there is a faster granule formation and higher granulation rate of 95%-97% pour toi.

Can we process 70% water content organic waste into organic fertilizer granules?

Bien sûr. You can choose to remove excessive moisture in organic waste before fertilizer granulation. Ici, le machine de déshydratation is an excellent choice. Not only reduce the watet conten of organic fertilizer material to 30% rapidement, but also no fuel requirement.

Haut 4 organic fertilizer granulators for sale

Though above processes, you can get high quality powdery organic fertilizer. If you want to further improve its quality, you need to convert it into granular fertilizer. Then how to turn powdery organic fertilizer into pellets? There are four methods you can use.

Disc granulation

Pan disc granulation is a kind of natural pellet making method. It makes use of the rotation of the disc to drive the raw materials to move upward. Then they will roll down and stick to each other. Enfin, they will form the round organic fertilizer granules. Pan granulator is a typical equipment, which employs disc granulation method. And it is an ideal choice for those who want to start a small organic plant. Because it has small capacity but high performance in granulation. Il peut produire 0.5-6 tons of organic fertilizer granules per hour. But it has a high granulation rate which reaches 93% and an economical price. So it is suitable for those who don’t have enough budget.

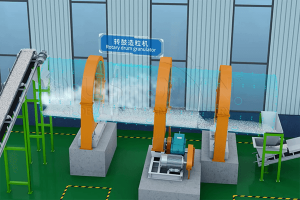

Rotary drum pelleting

Rotary drum pelleting also belongs to the natural granulation method. And the organic material will get squeezed together into fertilizer particles under the action of drum rotation. En SX, the most popular pelletizer, which uses this method, is rotary drum pelleting machine. If you need a granulator for large scale organic fertilizer granulation, it will be your best choice. We especially design the drum pelletizer SXZGZ-2080 and SXZGZ-3210, which has a large capacity of 8-15t/h and 15-30t/h. And you must want to know whether it can resist the erosion of such a large number of organic materials. Bien sûr, our rotary drum granulator not only has rubber linings to enhance corrosion resistance. But it also has material lifting plates to prevent fertilizer sticking to the wall.

Stirring teeth granulation

If you want to make organic fertilizer pellets with high strength, vous pouvez utiliser stirring teeth granulation method. It mainly granulates powdery organic fertilizer by two forces. High speed rotary mechanical agitation force and the resulting aerodynamic force. So compared to natural granulation, the organic fertilizer pellets produced by stirring teeth granulation have higher strength. Dans ce cas, we can provide new type organic fertilizer pelletizer for you. It is also called stirring teeth granulator.

Extrusion pelleting

Extrusion pelleting method, as name suggests, is mainly make granular organic fertilizer by extrusion force. Because there is nearly no water involved, subsequent drying and cooling is not needed. Donc, it can help you reduce the cost of organic fertilizer production. So if your budget is limited, it is your ideal choice. Pour ça, we can offer you granulateur à filière plate for small scale organic fertilizer granule making while granulateur à double rouleau for larger scale.

Rotary drum pelleting + Stirring teeth granulation

Except single granulation method, we also can provide you with organic fertilizer pelletizer with two pelleting ways. It is rotary drum churning pelletizer. Because of two methods usage, it can offer you higher granulation rate than others. And in order to increase its working efficiency, we design two motors for it. One for stirring teeth, another for rotary drum.

How to adjust the size of granules during organic fertilizer production?

If you want to make organic fertilizer pellets of different sizes, our equipment also can meet your requirements. You can change fertilizer size by following ways:

Regulate moisture content

During organic fertilizer granulating, controlling organic material moisture is the most common way to regulate the granule size. Moins d'eau, taille plus petite; beaucoup d'eau, plus grande taille. It is suitable for various pellet making machines, especially wet granulation equipment. Such as pan granulator, granulateur à tambour rotatif, stirring teeth pelletizer and rotary drum churning pelletizer.

Control the pan slope angle

If you plan to use disc granulator to prepare organic fertilizer, you also can regulate the final granule size by adjusting the pan slope angle. Forte pente, taille plus petite; pente lente, plus grande taille.

Adjust rotating speed

If you want to change fertilizer size during pelleting by rotary drum granulator, stirring teeth pelletizer and rotary drum churning pelletizer. Besides water content, you can finish it by adjusting the speed of the granulation machine. High speed, taille plus petite; low speed, plus grande taille.

Change mold

Then how to regulate organic fertilizer granule size when you use flat die pelletizer? You only need to choose the mold of the required size. We can provide you with mold for the production of 2-10 mm organic fertilizer columnar particles.

What you need to do before granulating organic fertilizer?

Do you want to prepare high quality organic fertilizer? Do you want to make your granulation process more smooth? There are something you must focus on, they are greatly in favor of better granulation of organic fertilizer.

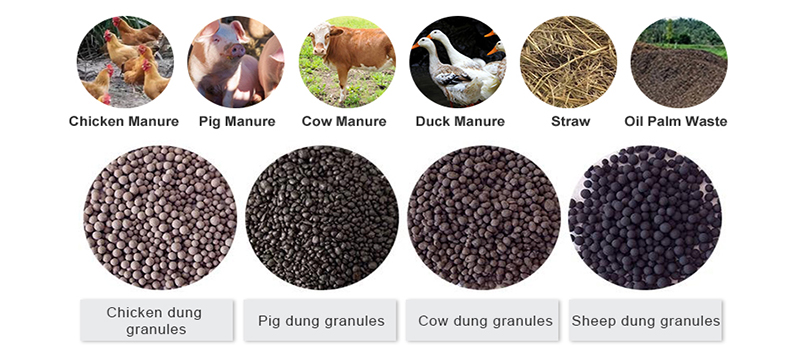

Collect materials

If you want to produce high quality organic fertilizer, you must pay attention to material selection. For organic fertilizer preparation, you can use poultry manure, déchets agricoles, boue, résidu de biogaz, etc as material. Parmi eux, poultry manure is the most common material for the production of organic fertilizer. Comme la bouse de vache, fumier de poulet, fumier de cheval, etc.. Because it is rich in nitrogen, phosphore, potassium, which are important in the growth of crops and plants. En outre, using fresh manure is better than old manure during organic fertilizer making.

Adjust the moisture content

Quand tu use fresh poultry manure to prepare organic fertilizer, you will find that it cannot be used directly. Because it is a mixture of solid manure and liquid, and has a high moisture content. À ce moment-là, you can treat it in two ways. D'abord, you can use some dry agricultural waste to balance the water content, such as straw, épi de maïs, peanut shell, etc.. If you want to finish it quickly, we recommend you use our machine de déshydratation. It can help you separate solids from liquid in a short time. And the moisture can be reduced to 30%.

Compostage

Composting is a key step to manufacturing high quality organic fertilizer production. It can remove harmful bacteria, pest eggs and grass seeds in animal manure. So manure will become harmless for the health of crops and humans. Durant ce processus, machine à composter les engrais can help you finish it easily. And you can add some fermentation strain to increase fermentation efficiency.

What you can do to improve the quality of organic fertilizer granules?

After organic fertilizer granulation, you will find that there still are some items you want to improve. Par exemple, uneven appearance, excess moisture, easy to stick after long time storage, etc.. Is there any solution for them to improve the quality of organic fertilizer granules? La réponse est oui. There are some fertilizer processing machines can help you a lot.

Granule polishing machine

If the shapes and sizes of your organic fertilizer pellets are different, using a machine de polissage d'engrais est un excellent choix pour vous. It is designed to make your fertilizer granules more round and look more beautiful. It is an ideal equipment for organic fertilizer to make spherical particles.

Sécheuse et glacière

The international requirement of organic fertilizer moisture is 14%, but the water content of granulated organic fertilizer is about 20%. So you need to further reduce the moisture content of organic fertilizer after granulation. À ce moment-là, machine à sécher and cooling equipment will be your good partner.

Coating machine

From above, we can know that keeping moisture content is important for organic fertilizer making. But it is also essential after production. Because after a long time storage, the finished organic fertilizer pellet will absorb the moisture from air and become easy to stick again. Dans ce cas, we recommend you to use fertilizer coating machine to add a film on your organic fertilizer granules. It not only prevents your fertilizer from sticking, but also from nutrient loss. Then you can improve the quality of your organic fertilizer pellets.

Why so many fertilizer suppliers choose to buy organic fertilizer granulator from SX?

When you want to buy organic fertilizer granulator, Usine d'équipement d'engrais SX will be your ideal choice. Pourquoi?

Applications étendues

Organic fertilizer granulator from SX has high adaptability, so it can be used for a variety of organic materials. Including chicken manure, bouse de vache, paille, sciure, boue, résidu de biogaz, etc.. So you have more options for organic fertilizer materials.

High quality equipment

All SX fertilizer equipment is made of high quality steel, which can increase the ability to resist wear and corrosion. So you can use it for a long time. Pour ça, we can provide you with relevant certificates.

Advanced technology

During organic fertilizer equipment manufacturing, we adopt many advanced equipment. Including plasma cutting machine, laser cutting machine, automatic bending machine, etc.. Guarantee the manufacturing accuracy of the granulator.

Economical price

SX is a source factory of organic fertilizer granulator, there is no extra charge for you. So we can provide you with high quality equipment at a favourable price. En outre, we can design the organic fertilizer production project according to your actual conditions, which include your budget.

Considerate service

Considerate service is also one of the reasons why fertilizer manufacturers are willing to buy granulator from SX. D'abord, upon receipt of customers’ information, we will promptly reply by telephone and email. During the sale, we will try our best to provide you with optimal project design according to your requirements. Après la vente, we can offer you guidance for installation, fonctionnement et entretien.