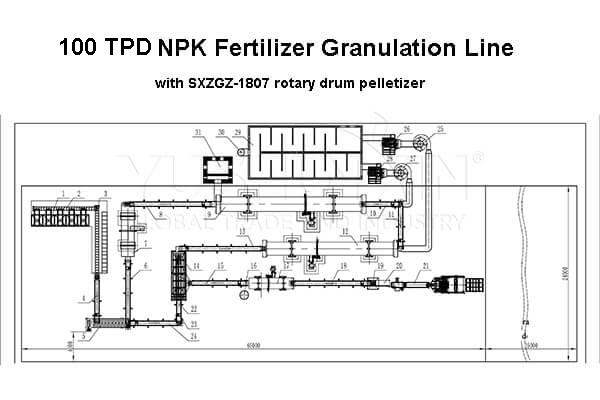

On 17th September 2022, a client from Turkey emailed us for finding a NPK NPK fertilizer making line of pellets. With urea, ammonium sulphate, diamonium phosphate, potassium sulphate and photasium chloride as materials, the customer plan to produce granular NPK fertilizer of 3-4 mm. Is there an automatic system with 100 tons/day output here? Of course. The SXZGZ-1807 rotary drum granulation line is an ideal choice. The following are the specific details of communication in this case:

Ptoject Overview

- Country: Turkey

- Capacité: 100 Tonnes/jour

- Material: urea, ammonium sulphate, diamonium phosphate, potassium sulphate and photasium chloride

- Requirement: 4-4mm NPK granules production

- Solution: 7 TPH Rotary drum granulation line

What capacity of NPK fertilizer making line do you need?

When you select equipment for your NPK fertilizer plant, you must know your expectant fertilizer capacity. This Turkish customer planned to prepare 100 tons of NPK fertilizer per day. Pour ça, there are two plans for your choice.

- If you want to keep the NPK fertilizer production line working 2 shifts a day, 10 hours a shift, we recommend you choose 5t/h NPK fertilizer production system.

- But if you plan to make it operate 2 shifts a day and 8 hours a shift, it is advisable to buy NPK fertilizer manufacturing line of the output of 7t/h.

Then you may be wondering why not keep the compound fertilizer production line working for 24 heures par jour? Because long working hours will accelerate the wear of fertilizer processing equipment. Proper rest can keep the fertilizer machine in use for a longer time.

Fianlly, the customer from Turkey choose to buy a 7 t/h NPK fertilizer granulation system.

Get your own NPK fertilizer granulation plan now!

Which granulating machine is suitable for your 7 t/h NPK compound fertilizer plant?

This fertilizer manufacturer from Turkey wanted to make NPK fertilizer into granules. And he inquired to us which granulating equipment is suitable for the production of NPK fertilizer. Pour ça, we recommend you choose granulateur à double rouleau or rotary drum pelletizer.

Double roller granulator for economical NPK granulation

If you want to save money and space of NPK fertilizer making, double roller granulator is the optimal option for you. It adopts méthode de granulation par extrusion sèche, which is nearly no water involved. So it doesn’t need drying and cooling processes to remove excessive moisture. This can greatly reduce the cost of equipment buying, factory rent, fuel consumption. But for a 7t/h NPK granule making plant setup, you need to buy a system with 2 sets of SXDG-4T roller press granulators.

Inquiry the double roller npk granulation line!

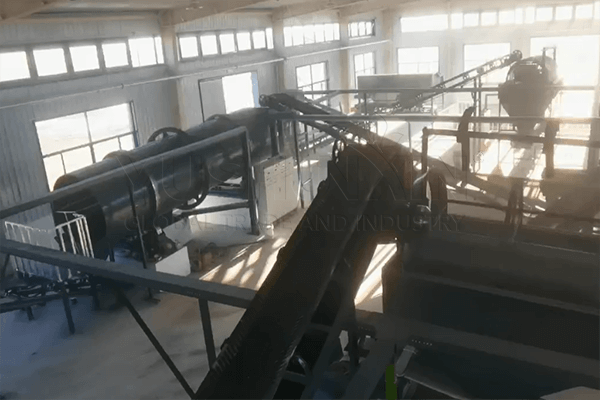

Rotary drum granulator with better erosion resistance

Mais, when you pay more attention to the erosion resistance of the NPK granulator with 7 ème, it is advisable to choose a SXZGZ-1807 rotary drum pelletizer. It has unique rubber lining to reduce the erosion from NPK granules processing. En outre, this pellet making machine mainly employs wet granulation method, which use liquid as binder to increase the adhesive force between chemical materials. This makes final NPK fertilizer granule with low possibility of pulverization and convenient for transport and storage.

Inquiry the double roller npk granulation line!

Finally, considering the project adopts materials of urea, ammonium sulphate, diamonium phosphate, potassium sulphate and photasium chloride, the Turkish customer prone to buy a system with erosion resistance. Therefore, he chose to buy rotary drum granulator for his NPK fertilizer making line.

Can the pellet making machine produce particles with a 3- 4 mm diameter?

This client from Turkey hoped his NPK fertilizer granules are round pellets and pellets size between 3- 4 mm in diameter. Can the rotary drum pelleting machine meet this requirement?

Of course, it can help you manufacture fertilizer particles with a diameter of 3-6 mm. En outre, it also can meet your requirement of NPK fertilizer pellets size regulation. Because it is designed with spraying device, which is used for the add of water or binder. Less water, smaller size; much water, bigger size. So you can freely produce NPK fertilizer particles of any size you need.

Can YUSHUNXIN provide a full automatic drum granulation system for NPK fertilizer preparation?

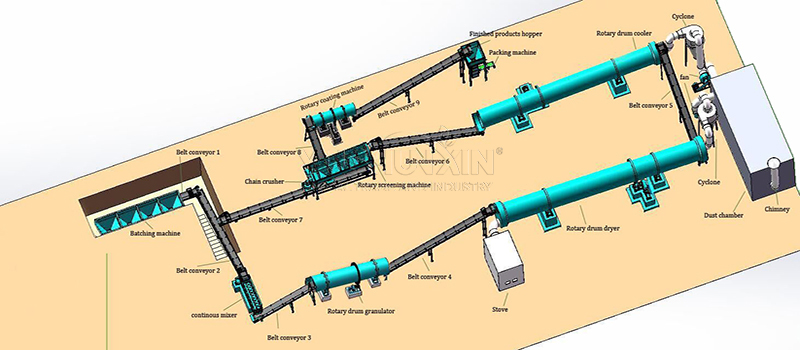

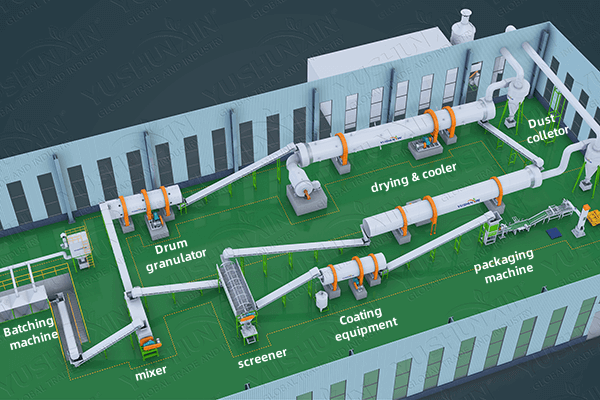

The Turkish customer told us he wants to buy a fully full automatic production line for granular NPK fertilizer production. Pour ça, the above rotary drum granulation line can fully meet the requirement. This NPK fertilizer making line consists of automatic batching machine, double shafts mixer, rotary drum granulator, séchoir rotatif, refroidisseur rotatif, machine de revêtement and granule packaging equipment. They are operated by an automatic control system. Therefore, by only employing a 2-3 workers, you can keep the whole NPK making line running.

The above are details about our communication with the customer from Turkey. En outre, except NPK fertilizer production line, we also can provide you with many other fertilizer making lines. Tel que Bulk blending fertilizer preparation line, organic fertilizer production line, ligne de fabrication d'engrais de bouse de vache, etc.. If you are interested in them, please contact us immediately.