Are you finding solutions for liquid fertilizer manufactruing? As a professional fertilizer equipment manufacturer. YUSHUNXIN can offer you not only business plan for making manure and urine into liquid organic fertilizer, but also NPK liquid fertilizer production line. It contains crushing, reaction, filtering, liquid filling and so on. En outre, as a fertilizer machine source factory, you can buy liquid fertilizer machines at a favorable price. If you want to start liquid organic or NPK fertilizer production as soon as possible, welcome to contact us for customized design.

Contact us for your liquid fertilizer making line immediately!

How to make liquid organic fertilizer from manaure?

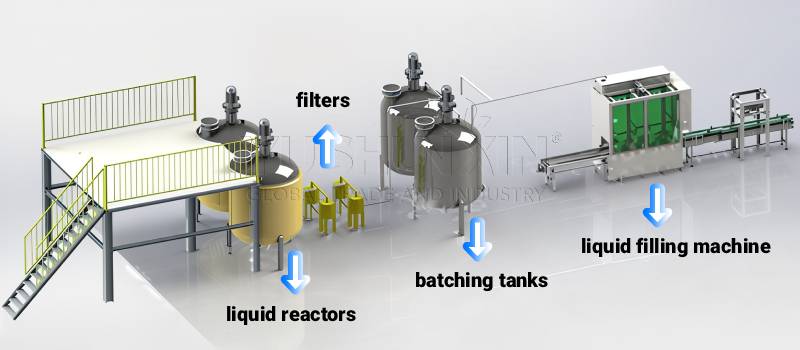

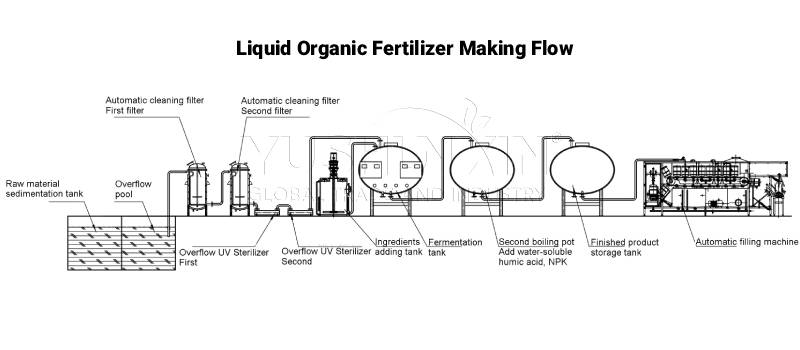

In general, for organic liquid fertilizer plant setup, the process contains 6 steps:

Manure liquid separation

Animal manure is an excellent material for liquid fertilizer making. But it is usually a mixture of liquid and solid. So you need to separate liquid manure from the solid first. How to separate liquid from solids? For industrial liquid fertilizer manufacturing, il est conseillé d'utiliser un manure solid-liquid separator. Only several minutes, you can distill liquid manure to start making organic liquid fertilizer. En outre, the left solid manure is suitable for solid organic fertilizer making.

Filtering to remove impurities

Then in order to ensure the high quality liquid fertilizer production, automatic filters will perform secondary and tertiary purifying on liquid animal manure. In this way, mini waste particles will be completely removed from your materials.

UV disinfection

Dans ce processus, disinfection of liquid fertilizer making material is necessary. Because raw manure liquid material contains various pathogens. Such as bacteria, virus, parasites, etc.. They will harm crops and plants. But with UV disinfection machines, you can make materials harmless quickly. And compared with chemical disinfection, it is more environmentally friendly.

Batching auxiliary materials

Due to making more profits from liquid fertilizer production line, besides manure liquid, we usually need to add some auxiliary materials. Therefore, you can prepare liquid fertilizer, which is suitable for local farming conditions. For example, adding micro elements and NPK materials to enrich the nutrients of final liquid fertilizer. Even, it can help you process liquid biofertilizer successfully. Or batching some fermentation agent to speed up liquid fertilizer fermentation.

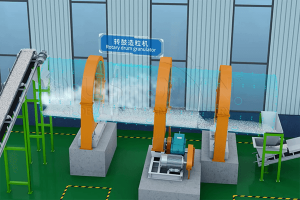

Liquid fertilizer reaction

Suivant, the most important step in liquid organic fertilizer manufacturing process – fermentation. It is key to converting nutrients into organic materials into forms that are more easily absorbed by plants. De plus, in this process, beneficial microorganisms, like actinomycetes, nitrifying bacteria, phosphatizing bacteria, etc.. can reproduce. And manure odor will disappear and fertilizer nutrient elements become more stable. Ici, we have professional reactors for liquid fertilizer preparation. It usesacier inoxydable as materials, which have high erosion-resistance.

Packaging with liquid filling system

Finally, packaging finished liquid fertilizer for easier transport, storage and use. YUSHUNXIN can offer you automatic liquid filling machine, which has characteristics of precise quantitative system, automatic filling, covering, étiquetage, etc.. So you can complete the liquid fertilizer packing in a short time. Ici, we can customize machines according to your bottle capacity. Tel que 1 liter, 5 liters or more.

What is the process of liquid npk fertilizer manufacturing?

Can the liquid fertilizer production line operate with NPK liiquid fertilizer making? Of course. The mechanial liquid npk fertilizer manufacturing process is as follows

How much does liquid fertilizer equipment cost?

Price of liquid fertilizer machines is an item most liquid fertilizer manufacturers focus on. In general, you need to prepare $50,000-$300,000 for a basic liquid fertilizer production line. Because of more refined design and stainless steel material adoption. Then, the precise quote is closely related to many aspects. Including capacity, machine types, conception du système, etc.. If you need more precise quote for your liquid fertilizer making machines, bienvenue à nous contacter immédiatement.

Can the production line make liquid fertilizer from cow dung?

The answer must be yes. Using this liquid fertilizer manufacturing line, you can choose to make liquid fertilizer from various organic waste. Comme le fumier de poulet, pig waste or other animal manure, both poultry manure and livestock poop. Of course, these contain cow dung liquid fertilizer preparation. En outre, you can add water soluble humic acid, water soluble NPK or other trace elements to enrich the nutrients of your liquid fertilizer according to local conditions.

How to process liquid fertilizer into bio type?

En outre, YUSHUNIN can offer you customized solutions for bio liquid fertilizer production. It is upgraded on the basic of standard liquid fertilizer manufacturing system. For this, there are 2 aspects auxquels vous devez prêter attention.

- Add functional bacteria agent during secondary chelation. Because the first liquid fertilizer chelation for organic waste harmful pathogens need a high temperature of 60℃. But to ensure the added microorganism survival while dissolving during liquid fertilizer production, it is advisable to keep it to 20-40 ℃.

- Removing impurities again by ultrafiltration membrane components. With membrane pore size is 0.1 μ m-1μ m, you remove tiny particles, spores fongiques, et résidus insolubles du bioengrais liquide de chélation secondaire. This is beneficial for quality improving and prevent liquid filling clogging.

Therefore, with proper equipment upgrades, the liquid fertilizer making line can manufacture high-quality biofertilizer. The products is better for drip irrigation and foliar spraying. This flexibility makes the production line more profitable for liquid fertilizer manufacturers who want to expand their product range.

Is there operational liquid fertilizer plant in Australia?

Of course. In the past over 20 years, we had helped many fertilizer manufacturers start their liquid fertilizer production business. For example,

The project of making organic liquid fertilizer from poultry manure in Australia avec 10 tons/day capacity. The customer focused on the 2 aspects for liquid fertilizer making. They are liquid organic fertilizer pathogens eliminate and 5 Atterrir 20 L liquid packing. Ici, we offered him liquid reactor with heating design, and flexible liquid filling equipment.

Additionally, there are also liquid cow dung fertilizer plant setup in Ethiopia, 50000 t/year liquid compound fertilizer making iline in Egypt, etc..

Get your own liquid fertilizer making solution now!

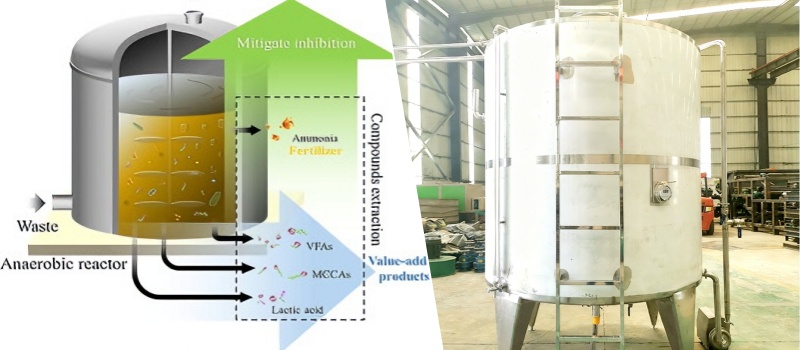

What method is used in organic liquid fertilizer reaction? Anaerobic or aerobic fermentation?

YUSHUNXIN liquid fertilizer fermentation system mainly makes use of anaerobic fermentation design. In liquid fertilizer reactor tank, there is an automatic air extraction system, which can create an anaerobic environment quickly for fast liquid fertilizer making. De plus, it has mixing blades inside. This is beneficial for improving anaerobic bacteria activity to decompose nutrients into smaller molecules that are easier to absorb.

How to make liquid fertilizer quickly?

For industrial liquid fertilizer production line, speed is essential. But how to prepare liquid fertilizer fast? There are 4 tips for your reference.

Add suitable bacteria

Comme mentionné ci-dessus, liquid fertilizer making mainly relies on bacteria to decompose materials. So you can add some extra beneficial bacteria to speed up the liquid fertilizer manufacturing process. Such as compound spores, compound yeasts, compound lactobacilli, compound enzyme preparations, etc..

Mixing various materials evenly

Then mixing is a method to make bacteria distribute evenly in raw materials. So it can fully play its role in facilitating the fermentation of liquid organic fertilizer. Ici, you don’t need to add a professional mixer. Our liquid fertilizer reactor tank has its own mixing shaft inside.

Heating liquid fertilizer

En outre, you can add a liquid heating tank in liquid fertilizer production line. Anaerobic microorganisms are generally more active in warm conditions. 30-40°C is considered the ideal temperature range for mesophilic anaerobic fermentation. At this temperature, the growth of microorganisms and the decomposition of organic matter are relatively rapid.

Buy automatic liquid fertilizer making machine

With high automation, there is a lower labor force cost and faster liquid fertilizer making process. Our whole liquid fertilizer manufacturing system is controlled by PLC control system. It can monitor and adjust the temperature, oxygen content, material status, etc in real time. In this way, you can create a better environment for liquid fertilizer making.

Is there more details about liquid fertilizer manufacturing process?

Why so many liquid fertilizer manufacturers choose to buy YUSHUNXIN liquid fertilizer production line?

After determining liquid fertilizer equipment you want to buy, it is necessary to find a reliable liquid fertilizer machine manufacturer. Ici, YUSHUNXIN is an excellent choice. There are 3 reasons.

High liquid fertilizer equipment quality

All liquid fertilizer equipment uses stainless steel as material, which can withstand the erosion from large scale liquid fertilizer processing for a long time. Then there are professional certificates of equipment quality for you.

Customized liquid fertilizer making project plan

In order to help you start liquid fertilizer making successfully, we will design production plan according to your requirements and actual conditions. Including capacity, matériel, budget, final product, etc.. It also contains customized liquid fertilizer equipment design charging.

Considerate after-sales services

After receiving liquid fertilizer equipment, we can offer you guidance for operations and installation. If you have any other things want to know, we will also provide you with the best solution as soon as possible.