With the increasing of organic fertilizer demand and the requirement of environment protection. More and more animal farm owners are willing to make animal manure into organic fertilizer. Et en général, they choose to start with small scale fertilizer production. Pour ça, you can choose a 1-2 t/h organic fertilizer making line. It can help you make organic waste into fertilizer quickly and easily. De plus, this project only needs a small investment, but can help you eliminate pollution of organic litter and earn more money simultaneously. Et YUSHUNXIN can provided you different business plans for your choice.

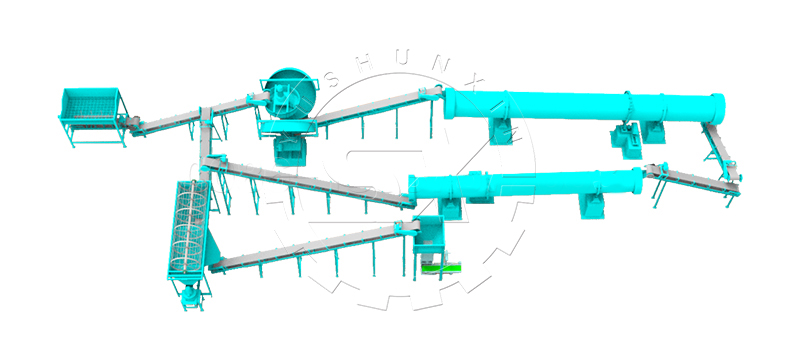

Organic Fertilizer Making Equipment

- Capacité: 1-2 ème

- Conception: Retourneur de compost à rainure, concasseur semi-humide, pan granulator/ flat die granulator, déshydrateur, machine de dosage statique, mixer, écran, séchoir, glacière, machine à emballer, etc.

- Eqeuipment Material: Acier au carbone Q235, alliage

- Tension:220v/380v/415v/440v/480v(50Hz/60 Hz)

- Application: Boussier de vache/crottes de poulet/fumier de porc/fumier de chèvre, etc à l'engrais

Click here for your customized small scale organic fertilizer making plan!

Who needs this 1-2 t/h organic fertilizer making line?

Whose capacity is 15,000 tonnes / year or less

If you plan to make the organic fertilizer manufacturing system work 10 hours a shift and 2 shifts a day. It can help you prepare about 12,000 tons of fertilizer a year. And when you keep it running for 8 hours a shift and 3 shifts per day. The yearly capacity of this 1-2 t/h organic fertilizer making line can increase to 15,000 tonnes. Is it suitable for smaller scale organic fertilizer manufacturing. Bien sûr, you can realize it by reducing the working time of this system.

Whose materials volume is about 3-120 tonnes par jour

Généralement, the fresh manure is a mixture of solid and water. And what we use to make organic fertilizer is the solid part, which only accounts for 1/3 of the whole. So generally speaking, producing 1 ton of solid organic fertilizer (10% humidité)needs 3 tons of fresh animal manure from the farm. So if your material capacity is lower than 120 j/j, tu peux choisir ceci 1-2 t/h organic fertilizer making line.

Click here for your customized 1-2 t/h organic fertilizer making plan!

How to design a low cost 1-2 t/h organic fertilizer making line?

Quand tu veux commencer 1-2 t/h organic fertilizer manufacturing at a low cost, making manure into powder organic fertilizer is an excellent choice. And you can reduce the number of fertilizer machines. En général, il y a 2 organic fertilizer processing equipment you must buy for the 1-2t/h powdery organic fertilizer making line.

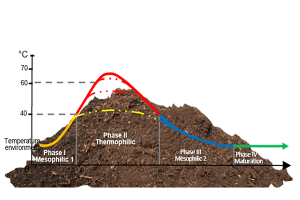

Small scale groove type compost machine

Compostage is an indispensable step of organic fertilizer production, whether you want to prepare it into powder or granule. Because in this process, the harmful bacteria, pest eggs and grass seeds will be killed by high temperature. So you use manure as fertilizer without any harm to crops and plants. En outre, pour 1-2 t/h organic fertilizer making line, we recommend you choose small scale retourneur de compost à rainure. Its turning width can reach 2.5-5 m and turning depth is about 0.8 m. Its price is only $6,500-$15,000.

| Modèle | Main motor(kW) | Moving motor(kW) | Lifting motor(kW) | Turing width(mm) | Turing depth(mm) |

|---|---|---|---|---|---|

| SXCF-2500 | 15 | 1.5 | 0.75 | 2500 | 800 |

| SXCF-3000 | 18.5 | 1.5 | 0.75 | 3000 | 800 |

| SXCF-4000 | 15*2 | 1.5 | 0.75 | 4000 | 800 |

| SXCF-5000 | 18.5*2 | 1.5 | 0.75 | 5000 | 800 |

Semi-wet material crusher SXSF-60

Alors machine de concassage is also essential for power organic fertilizer preparation. Before composting, you can use it to crush agglomerated manure into smaller size materials. De cette façon, organic materials can fully contact with oxygen and finish fermentation aérobie of organic material faster. De plus, after composting, it can help you grind compost into finer powder, which is more easier to use. Because organic waste usually has high moisture, semi-wet material crusher is an ideal choice for you. And SXSF-60 is suitable for 1-2 t/h organic fertilizer manufacturing.

Which granulation equipment is suitable for 1-2t/h organic fertilizer making line?

Provided you want to further improve the quality of your organic fertilizer, you can make it into pellets. Pour 1-2 t/h à petite échelle granulation d'engrais organique, there are disc pellet machine and flat die granulation equipment for your choice. You can choose the best one according your needs.

Economical flat die granulator

If you want to make organic compost granules at a low cost, nous vous recommandons d'acheter notre flat die granulation machine. It mainly adopts méthode de granulation sèche, which relies on extrusion force between rotating roller and molds to make organic manure into columnar pellets. So there is nearly no water involved in the whole organic fertilizer pelleting process. And there is no cost of drying and cooling. En outre, the price of flat die pellet equipment is economical. When you use dry manure (10% humidité) as material, the machine is the most option for 1-2 t/h output of organic fertilizer granules.

Disc pellet machine with over 93% taux de granulation

Provided you prefer to rounded organic fertilizer pellet and need a higher granulation rate, disc granule machine est conçu pour vous. Pour une chose, it has a high granulation rate of more than 93%. C'est, with the same amount of organic materials, pan granulation machine can produce more pellets in a certain period of time. Pour un autre, it also has a favourable price of $3,000-$16,000. So it is popular with fertilizer manufacturers who want to make manure fertilizer particles at a low cost. And for 1-2 t/h organic fertilizer granule production, we recommend you choose SXYZ-2500 pan pellet machine, which has an output of 1.5-2 ème.

| Équipement | Modèle | Capacité (ème) | Granule Shape (mm) | Taille des granules (mm) | Alimentation en humidité |

|---|---|---|---|---|---|

| Flat Die Granulator | SXPM-500 | 1.5-2 | colonne | 2-10 | lower 10% |

| Disc Pan Granulator | SXYZ-2500 | 1.5-2 | round | 1-8 | 20%-40% |

can we turn flat die granulation fertilizer into rounded?

Bien sûr. If you want to turn pellets into more round shape, vous pouvez utiliser un polishing equipment after flat die pelletizer. It can help you a lot with fertilizer appearance improvement.

How to further upgrade the 1-2t/h organic fertilizer manufacturing line?

Besides composting machine, crusher and granulator, there are many other machines that are beneficial for organic fertilizer production. If you want to further upgrade the 1-2 t/h organic fertilizer manufacturing line, you can purchase the organic fertilizer equipment as follows:

Manure dewatering machine: A high moisture of materials will hinder the fermentation and composting of organic waste. And the most suitable water content of compost making is 45%-65%. SX machine de déshydratation can remove excessive water from manure easily and effectively

Machine de dosage statique: It is used to add auxiliary materials to enrich the nutrient of your organic fertilizer. De plus, équipement de dosage can help you feed various materials strictly in accordance with the formula proportion.

SXWJ-7015 horizontal mixer: Mixer will help you blend various organic materials evenly. This can prevent your final fertilizer from nutrients imbalance.

SXGS-1020 screening machine: Tamiseur is the key process to distinguish qualified from unqualified fertilizers. And the unqualified pellets will be returned to form into pellet again. Cela peut réduire considérablement le gaspillage de matériaux.

SXHG-0808 dryer and SXLQ-0808 glacière: If you granulate organic powder with wet granulation method, séchoir and cooler is necessary. They can further remove the water in granule and improve the quality of your granular organic fertilizer.

BM1200×4000 coating machine: Revêtement will add a protective film to your organic fertilizer granule. So it can be stored for a longer time.

Machine d'emballage: Après packaging, the finished manure fertilizer is easier to store and transport. Et vous pouvez les emballer dans des sacs de différents volumes, qui peut répondre aux différents besoins de vos clients. And SX can provide you with both granule packing machine and powder fertilizer packing scale.