La línea de producción de fertilizantes orgánicos en polvo es el método más sencillo para convertir residuos orgánicos en fertilizante. Solo 5 pasos, producirás fertilizante orgánico de alta calidad. compostaje, procesamiento por lotes de materiales, aplastante, cribado y embalaje. Si desea deshacerse del estiércol de vaca, estiércol de pollo, excremento de cabra o desechos de hongos, etc., puede satisfacer plenamente sus necesidades. Además, En general, tiene características de menor ocupación de espacio, bajo costo, fácil operación, etc.. Por lo tanto, Hay muchos principiantes en la fabricación de fertilizantes que invierten en el proyecto.. Si estas interesado en ello, bienvenido a contactarnos para más detalles.

Parámetros principales

- Capacidad: 1-20 t/h

- Producto: Polvo

- Costo: $10,000-$90,000

- Diseño: volteador de abono, alimentador, trituradora, pantalla, maquina empacadora, etc.

- Material del equipo: Acero al carbono Q235/Aleación

- Solicitud: estiércol de vaca, caca de pollo, estiércol de cerdo, estiércol de cabra, etc al fertilizante

4 Ventajas de convertir fertilizante orgánico en polvo

Cuando se eliminan los desechos de estiércol animal en fertilizantes orgánicos., La línea de fabricación de fertilizantes orgánicos en polvo es una excelente opción.. Especialmente, si eres principiante en la producción de fertilizantes orgánicos. Por qué? Porque tiene ventajas de precio favorable., menos área necesaria, Fácil operación y eliminación de diversos residuos orgánicos..

Por qué el compostaje de abono orgánico es el primer paso en la línea de producción de fertilizantes orgánicos en polvo?

Pero antes de preparar abono orgánico en polvo., hay un paso necesario requerido. Es compostaje y fermentación de abono orgánico.. Durante este proceso, El microorganismo en el material del estiércol descompondrá la materia orgánica y generará altas temperaturas para matar las bacterias dañinas., huevos de plagas y semillas de pasto. Así los residuos orgánicos ya no producirán olores y pondrán en peligro la salud de animales y humanos.. De este modo, Es adecuado para la elaboración de fertilizantes orgánicos.. Pero cómo hacer bien el abono orgánico? La máquina de compost YUSHUNXIN puede ayudarte mucho. Puede mantener la temperatura del material orgánico entre 65 y 70 ℃., cuál es la temperatura óptima para la fermentación de fertilizantes. Y diseñamos varios máquinas de compostaje industriales para tu elección.

Máquina de compostaje de fertilizantes a gran escala

Si tienes un compostaje a gran escala, te recomendaremos volteador de abono tipo rueda. Porque puede procesar abono fertilizante en el surco de fermentación con un ancho de 10-30 m y una profundidad de 1-3 metro. Que es más alto que otros volteadores de abono para fertilizantes orgánicos.. Además, Reemplazamos la rueda giratoria simple por ruedas giratorias dobles.. De este modo, Puede proporcionarle un mejor efecto de fermentación de su procesamiento de abono orgánico a gran escala..

Equipos de fermentación de fertilizantes a pequeña escala.

Pero cuando planeas preparar fertilizante orgánico a pequeña escala, volteador de compost en hileras es la mejor opción para ti. En general, Puede cumplir plenamente con sus requisitos de procesamiento de 500-1500㎡ de material orgánico en largas hileras por hora.. Además, Adopta el método de fermentación molida., lo que puede reducir en gran medida el costo de la construcción de infraestructura de zanjas de fermentación.

Tanque de fermentación de fertilizantes más rápido

Además, puedes elegir tanque de fermentación de fertilizantes orgánicos. Que es adecuado para un abono de fertilizantes orgánicos más rápido que produce una fermentación de estiércol en espacios pequeños.. Suele iniciar el compostaje en un ambiente cerrado., que puede aislar las influencias del mundo exterior. usándolo, puedes completar el proceso inofensivo de la basura orgánica dentro 10 horas. ¿Qué es más?, Lo equipamos especialmente con sistema de tratamiento de gas., que puede cumplir con sus requisitos para la fabricación de compost amigable con el medio ambiente.

| Equipo | Capacidad | Tiempo de comodidad | Área (㎡) | Abierto / Cerrado |

|---|---|---|---|---|

| Volteador de abono tipo rueda | 10-20 t/h | 15-20 días | Depende de la capacidad | Abierto |

| Máquina de compostaje en hileras | 25-750 m³/h | 15-20 días | Depende de la capacidad | Abierto |

| Compostador en recipiente | 5-150 m³/lote | 10-15 días | 10-30 ㎡ | Cerrado |

Cómo garantizar el procesamiento requerido de fertilizante orgánico en polvo.?

Después de la preparación del abono, El primer paso para hacer fertilizante orgánico en polvo es la alimentación de materiales.. En ese tiempo, Usar un montacargas para transportar material compostado es una excelente opción para usted. Necesitas introducir abono en alimentador de carretilla elevadora (También se conoce como alimentador tipo cargador.), que desempeña un papel de lugar de almacenamiento temporal. También es un puente para contactar la fabricación de abono fertilizante con la línea de producción de fertilizantes orgánicos en polvo..

¿Y se puede bloquear con material de abono como alimentador de abono orgánico?? Por supuesto que no. Nuestros ingenieros mejoran especialmente sus diseños para evitar bloqueos.. Primero, Tiene una malla filtrante en la parte superior para eliminar piedras grandes., pasteles y pasto. Y también aumentamos el ángulo inclinado de la pared y el tamaño del puerto de descarga para que el material caiga rápidamente.. Además, para evitar que el material se pegue a la pared, Lo equipamos con eje agitador y motor vibratorio.. Por lo tanto, El material no bloqueará el puerto de descarga..

Cómo eliminar la aglomeración y el apelmazamiento durante la fabricación de fertilizantes en polvo?

Cuando conviertes el abono en fertilizante orgánico en polvo, encontrará que hay aglomerado y apelmazamiento en el material orgánico.. Afectará el uso de fertilizantes orgánicos en polvo terminados y reducirá la disposición de compra de los clientes.. Entonces necesitas triturarlo hasta convertirlo en un polvo fino.. Aquí, maquina trituradora de fertilizantes profesional te puede ayudar mucho. Y para la producción de fertilizantes orgánicos., Le recomendamos elegir trituradora vertical y trituradora de material semihúmedo..

Cómo separar el fertilizante orgánico en polvo calificado del no calificado?

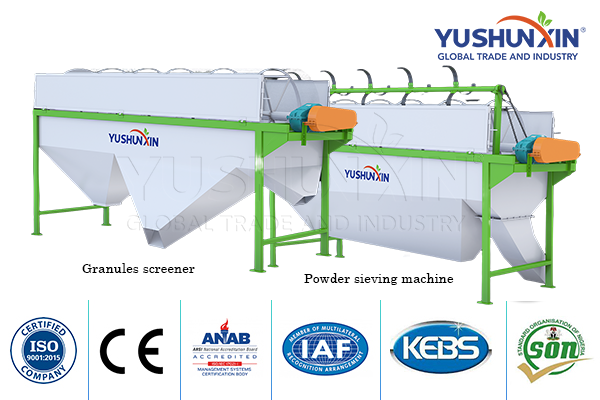

Después de aplastar, Es posible que el fertilizante en polvo todavía contenga algún pequeño aglomerado que no cumpla con sus requisitos.. Entonces, ¿cómo separarlo del fertilizante orgánico en polvo calificado?? Para esto, diseñamos especializados cribadora de tambor rotatorio para fertilizante en polvo. Tiene dos puertos de descarga., Uno se utiliza para descargar fertilizante en polvo calificado y otro está diseñado para producción no calificada.. Luego, los productos no calificados serán devueltos para procesarse nuevamente.. Por lo tanto, la máquina cribadora de tambor giratorio juega un papel importante en la fabricación de fertilizantes orgánicos en polvo..

¿Qué otros equipos se necesitan para la línea de producción de fertilizantes orgánicos en polvo??

Además del equipo de fertilizantes mencionado anteriormente., ¿Necesita otras máquinas en la producción de fertilizante orgánico en polvo?? Por supuesto, además del alimentador de carretilla elevadora, maquina trituradora y cribadora de polvo, El equipo de embalaje y la cinta transportadora también contribuyen en gran medida a la fabricación de fertilizantes en polvo de alta calidad..

Equipo de embalaje

El embalaje es el paso final de la línea de producción de fertilizantes orgánicos en polvo.. en este proceso, Máquina envasadora YUSHUNXIN Puede ayudarle a terminar el embolsado de polvo de forma fácil y rápida.. Porque puede embolsar fertilizante orgánico en polvo de forma automática y cuantitativa.. Y la precisión cuantitativa del sistema puede alcanzar el 2‰. Además, adopta la estructura integrada, que puede terminar de empacar y sellar simultáneamente. Sólo dos trabajadores, Puedes completar todos los trabajos de embolsado de fertilizantes en polvo..

Cinta transportadora

La cinta transportadora es necesaria para todo tipo de líneas de producción de fertilizantes.. Incluye línea de fabricación de fertilizantes orgánicos en polvo.. Porque es el puente entre las dos máquinas para transportar materiales orgánicos de un equipo a otro.. Y para cumplir con los diferentes requisitos de los clientes., Diseñamos varios tamaños de cintas transportadoras.. Todas sus correas están hechas de cauchos anticorrosión para garantizar una larga vida útil..

Últimos casos exitosos de instalación de plantas de fertilizantes orgánicos en polvo

¿Existe una planta operativa de producción de fertilizantes energéticos como referencia?? Por supuesto. sobre el pasado 20 años, Hemos ayudado a muchos fabricantes de fertilizantes en polvo a iniciar su negocio con éxito.. Como 2000 Estiércol de vaca para convertir fertilizante en polvo en México, Producción de fertilizantes en polvo de residuos de digestato en Uruguay., etc..

¿Qué puede hacer YUSHUNXIN? Proporcionarle producción de fertilizantes orgánicos en polvo.?

Después de decidir comprar una línea de producción de polvo, debes considerar donde comprarlo? y cual proveedor de equipos de fertilizantes es confiable? SX será una excelente opción para ti, porque puede ofrecerle ayuda de la siguiente manera:

Máquinas fertilizantes de gama completa

Del precompostaje al embalaje, SX puede proporcionarle todos los equipos de una línea completa de fabricación de fertilizantes.. Ya sea que necesite una máquina para polvo o gránulos, organico o compuesto, Fabricación de fertilizantes a pequeña o gran escala., Podemos ofrecerle el mejor equipo..

Precio favorable

SX puede proporcionarle una máquina fertilizante de alta calidad a un precio favorable. Porque cuenta con tecnología avanzada en la fabricación de máquinas fertilizantes., que puede reducir el costo. Además, Es la fábrica de origen de equipos de fertilizantes., Así que no hay ningún cargo extra que tengas que pagar..

Diseño de proyecto personalizado

Si no sabes cómo configurar tu planta de fertilizantes, Podemos ofrecer ayuda en este aspecto.. Sólo tú nos cuentas la información sobre el material., área de fábrica, capacidad, presupuesto, etc.. Diseñaremos libremente el proyecto según sus requisitos..

Servicio postventa considerado

El servicio posventa también es una de las razones por las que tantos fabricantes de fertilizantes eligen SX. despues de la venta, Podemos proporcionarle orientación sobre cómo utilizar la máquina correctamente y cómo mantenerla.. Si tiene alguna dificultad en la preparación de su fertilizante, También puedes contactarnos para una solución..

Si desea convertir aún más el polvo en gránulos de fertilizante orgánico, También hay muchas soluciones para ti en YUSHUNXIN.. Como Línea económica de granulación con prensa de rodillos., sistema peletizador de disco a pequeña escala, plan de granulación de tambor rotatorio a gran escala, etc.. Además, también Línea de fabricación de fertilizantes orgánicos líquidos. para ti. Bienvenido a contactarnos para sus propias máquinas para fabricar fertilizantes y planes de negocios ahora.!