¿Está encontrando soluciones para la fabricación de fertilizantes líquidos?? como un fabricante profesional de equipos de fertilizantes. YUSHUNXIN puede ofrecerle no sólo un plan de negocios para convertir estiércol y orina en fertilizante orgánico líquido, sino también línea de producción de fertilizantes líquidos NPK. Contiene trituración, reacción, filtración, llenado de líquido, etc.. Además, como fábrica de fuentes de máquinas fertilizantes, Puedes comprar máquinas de fertilizantes líquidos a un precio favorable.. Si desea iniciar la producción de fertilizantes líquidos orgánicos o NPK lo antes posible, bienvenido a contactarnos para un diseño personalizado.

Contáctenos de inmediato para su línea de producción de fertilizantes líquidos!

Cómo hacer fertilizante orgánico líquido a partir de manaure.?

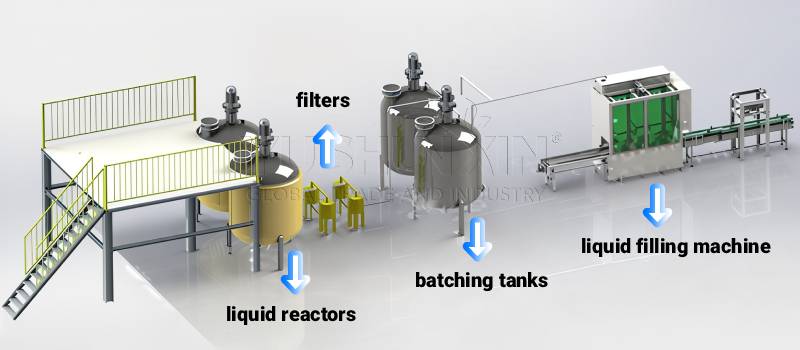

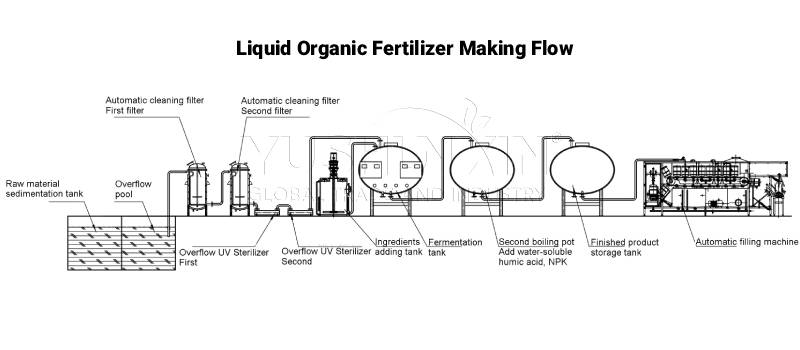

En general, para instalación de plantas de fertilizantes líquidos orgánicos, el proceso contiene 6 pasos:

Separación de líquido de estiércol

El estiércol animal es un material excelente para la elaboración de fertilizantes líquidos.. Pero suele ser una mezcla de líquido y sólido.. Por lo tanto, primero es necesario separar el estiércol líquido del sólido.. Cómo separar líquidos de sólidos? Para la fabricación de fertilizantes líquidos industriales, es recomendable utilizar un separador sólido-líquido de estiércol. Solo unos minutos, Puedes destilar estiércol líquido para empezar a hacer fertilizante líquido orgánico.. Además, el estiércol sólido dejado es apto para elaboración de fertilizantes orgánicos sólidos.

Filtrado para eliminar impurezas.

Luego, para garantizar la producción de fertilizantes líquidos de alta calidad., Los filtros automáticos realizarán una depuración secundaria y terciaria del estiércol líquido.. De este modo, Las minipartículas de desecho se eliminarán por completo de sus materiales..

desinfección ultravioleta

en este proceso, Es necesaria la desinfección del material que produce fertilizantes líquidos.. Porque el material líquido del estiércol crudo contiene varios patógenos. Como las bacterias, virus, parásitos, etc.. Dañarán cultivos y plantas.. Pero con máquinas de desinfección UV, Puedes hacer que los materiales sean inofensivos rápidamente.. Y en comparación con la desinfección química, es más amigable con el medio ambiente.

Dosificación de materiales auxiliares.

Debido a la obtención de mayores ganancias con la línea de producción de fertilizantes líquidos, además del líquido de estiércol, Generalmente necesitamos agregar algunos materiales auxiliares.. Por lo tanto, puedes preparar fertilizante liquido, que es adecuado para las condiciones agrícolas locales. Por ejemplo, añadiendo microelementos y materiales NPK para enriquecer los nutrientes del fertilizante líquido final. Incluso, puede ayudarte procesar biofertilizante líquido exitosamente. O mezclar algún agente de fermentación para acelerar la fermentación de fertilizantes líquidos..

Reacción de fertilizante líquido

Próximo, el paso más importante en el proceso de fabricación de fertilizantes orgánicos líquidos – fermentación. Es clave para convertir los nutrientes en materiales orgánicos en formas que las plantas absorban más fácilmente.. Además, en este proceso, microorganismos beneficiosos, como actinomicetos, bacterias nitrificantes, bacterias fosfatizantes, etc.. puede reproducirse. Y el olor a estiércol desaparecerá y los elementos nutrientes de los fertilizantes se volverán más estables.. Aquí, Contamos con reactores profesionales para preparación de fertilizantes líquidos.. se utilizaacero inoxidable como materiales, que tienen alta resistencia a la erosión.

Envasado con sistema de llenado de líquido.

Finalmente, Embalaje de fertilizante líquido terminado para facilitar el transporte., almacenamiento y uso. YUSHUNXIN puede ofrecerle una máquina llenadora automática de líquidos., que tiene características de sistema cuantitativo preciso, llenado automático, cubierta, etiquetado, etc.. Para que puedas completar el envasado de fertilizante líquido en poco tiempo.. Aquí, Podemos personalizar las máquinas según la capacidad de su botella.. Como 1 litro, 5 litros o más.

¿Cuál es el proceso de fabricación de fertilizantes líquidos npk??

¿Puede la línea de producción de fertilizantes líquidos funcionar con la producción de fertilizantes líquidos NPK?? Por supuesto. El proceso de fabricación de fertilizantes líquidos npk mecánicos es el siguiente

¿Cuánto cuesta el equipo de fertilizante líquido??

El precio de las máquinas de fertilizantes líquidos es un elemento en el que se centran la mayoría de los fabricantes de fertilizantes líquidos.. En general, necesitas prepararte $50,000-$300,000 para una línea de producción de fertilizantes líquidos básicos. Debido a un diseño más refinado y a la adopción de material de acero inoxidable. Entonces, la cita precisa está estrechamente relacionada con muchos aspectos. Incluyendo capacidad, tipos de máquinas, diseño del sistema, etc.. Si necesita una cotización más precisa para sus máquinas productoras de fertilizantes líquidos, bienvenido a contactarnos inmediatamente.

¿Puede la línea de producción producir fertilizante líquido a partir de estiércol de vaca??

La respuesta debe ser si.. Usando esta línea de fabricación de fertilizantes líquidos, Puedes optar por hacer fertilizante líquido a partir de diversos residuos orgánicos.. Como estiércol de pollo, excrementos de cerdo u otros estiércol animal, tanto estiércol de aves como excremento de ganado. Por supuesto, estos contienen Preparación de fertilizante líquido con estiércol de vaca.. Además, Puedes agregar ácido húmico soluble en agua., NPK soluble en agua u otros oligoelementos para enriquecer los nutrientes de su fertilizante líquido según las condiciones locales.

Cómo procesar fertilizante líquido en tipo biológico?

Además, YUSHUNIN puede ofrecerle Soluciones personalizadas para la producción de fertilizantes biolíquidos.. Está actualizado sobre el sistema básico de fabricación de fertilizantes líquidos estándar.. Para esto, hay 2 aspectos a los que debes prestar atención.

- Agregue un agente bacteriano funcional durante la quelación secundaria.. Porque la primera quelación de fertilizantes líquidos para patógenos dañinos de desechos orgánicos necesita una temperatura alta de 60 ℃. Pero para garantizar la supervivencia de los microorganismos añadidos mientras se disuelven durante la producción de fertilizantes líquidos, es aconsejable mantenerlo en 20-40 ℃.

- Quitar impurezas nuevamente por componentes de membrana de ultrafiltración. Con la membrana el tamaño de los poros es 0.1 µm-1μm, eliminas partículas diminutas, esporas de hongos, y residuos insolubles del biofertilizante líquido de quelación secundaria.. Esto es beneficioso para mejorar la calidad y evitar obstrucciones en el llenado de líquidos..

Por lo tanto, con actualizaciones de equipo adecuadas, La línea de fabricación de fertilizantes líquidos puede fabricar biofertilizantes de alta calidad.. El producto es mejor para riego por goteo y pulverización foliar.. Esta flexibilidad hace que la línea de producción sea más rentable para los fabricantes de fertilizantes líquidos que desean ampliar su gama de productos..

¿Existe una planta operativa de fertilizantes líquidos en Australia??

Por supuesto. En el pasado 20 años, Hemos ayudado a muchos fabricantes de fertilizantes a iniciar su negocio de producción de fertilizantes líquidos.. Por ejemplo,

el proyecto de Fabricación de fertilizantes líquidos orgánicos a partir de estiércol de aves en Australia. con 10 toneladas/día de capacidad. El cliente se centró en el 2 aspectos para la fabricación de fertilizantes líquidos. Son abonos orgánicos líquidos que eliminan los patógenos y 5 Tierra 20 L embalaje líquido. Aquí, Le ofrecimos un reactor líquido con diseño de calefacción., y equipos de llenado de líquidos flexibles.

Además, también hay Instalación de una planta de fertilizantes líquidos con estiércol de vaca en Etiopía, 50000 t/año de fertilizante compuesto líquido que produce iline en Egipto, etc..

Obtenga su propia solución para producir fertilizantes líquidos ahora!

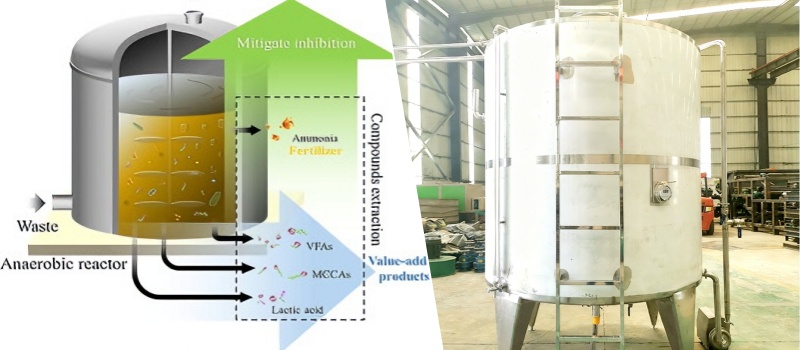

¿Qué método se utiliza en la reacción de fertilizantes líquidos orgánicos?? Fermentación anaeróbica o aeróbica.?

El sistema de fermentación de fertilizantes líquidos YUSHUNXIN utiliza principalmente un diseño de fermentación anaeróbica. En tanque reactor de fertilizante líquido, hay un sistema automático de extracción de aire., que puede crear un ambiente anaeróbico rápidamente para una rápida producción de fertilizantes líquidos.. Además, tiene paletas mezcladoras en su interior. Esto es beneficioso para mejorar la actividad de las bacterias anaeróbicas para descomponer los nutrientes en moléculas más pequeñas que son más fáciles de absorber..

Cómo hacer fertilizante líquido rápidamente?

Para línea de producción de fertilizantes líquidos industriales., la velocidad es esencial. Pero cómo preparar fertilizante líquido rápidamente? Hay 4 consejos para su referencia.

Añadir bacterias adecuadas

Como se mencionó anteriormente, La fabricación de fertilizantes líquidos se basa principalmente en bacterias para descomponer los materiales.. Así que puedes agregar algunas bacterias beneficiosas adicionales para acelerar el proceso de fabricación de fertilizantes líquidos.. Como esporas compuestas., levaduras compuestas, lactobacilos compuestos, preparaciones enzimáticas compuestas, etc..

Mezclar varios materiales de manera uniforme

Entonces mezclar es un método para hacer que las bacterias se distribuyan uniformemente en las materias primas.. Puede desempeñar tan plenamente su papel a la hora de facilitar la fermentación del fertilizante orgánico líquido.. Aquí, no es necesario agregar una batidora profesional. Nuestro tanque reactor de fertilizante líquido tiene su propio eje de mezcla en el interior..

Fertilizante líquido calefactor

Además, Puede agregar un tanque de calentamiento líquido en la línea de producción de fertilizantes líquidos.. Los microorganismos anaeróbicos son generalmente más activos en condiciones cálidas.. 30-40°C se considera el rango de temperatura ideal para la fermentación anaeróbica mesófila. A esta temperatura, El crecimiento de microorganismos y la descomposición de la materia orgánica son relativamente rápidos..

Comprar máquina automática para fabricar fertilizantes líquidos

Con alta automatización, Hay un menor costo de mano de obra y un proceso de fabricación de fertilizantes líquidos más rápido.. Todo nuestro sistema de fabricación de fertilizantes líquidos está controlado por un sistema de control PLC.. Puede monitorear y ajustar la temperatura., contenido de oxígeno, estado material, etc. en tiempo real. De este modo, Puedes crear un mejor ambiente para la producción de fertilizantes líquidos..

¿Hay más detalles sobre el proceso de fabricación de fertilizantes líquidos??

¿Por qué tantos fabricantes de fertilizantes líquidos eligen comprar la línea de producción de fertilizantes líquidos YUSHUNXIN??

Después de determinar el equipo de fertilizante líquido que desea comprar, es necesario encontrar un fabricante confiable de máquinas de fertilizantes líquidos. Aquí, YUSHUNXIN es una excelente opción.. Hay 3 razones.

Equipos de fertilizantes líquidos de alta calidad.

Todos los equipos de fertilizantes líquidos utilizan acero inoxidable como material., que puede resistir la erosión del procesamiento de fertilizantes líquidos a gran escala durante mucho tiempo. Entonces disponemos de certificados profesionales de calidad de equipos para usted..

Plan de proyecto personalizado para la fabricación de fertilizantes líquidos.

Para ayudarle a comenzar a producir fertilizantes líquidos con éxito, Diseñaremos un plan de producción de acuerdo con sus requisitos y condiciones reales.. Incluyendo capacidad, material, presupuesto, producto final, etc.. También contiene carga de diseño de equipo de fertilizante líquido personalizado..

Servicios postventa considerados

Después de recibir equipo de fertilizante líquido., Podemos ofrecerle orientación para las operaciones y la instalación.. Si tienes alguna otra cosa que quieras saber., También le proporcionaremos la mejor solución lo antes posible..