En el proceso de eliminación del estiércol de vaca., el secado es necesario. Ya sea que planees utilizar estiércol de vaca como fertilizante o combustible. La exposición a la luz solar llevará mucho tiempo.. Entonces, ¿cómo secar rápidamente el estiércol de vaca?? Con muchos años de experiencia en la fabricación de equipos fertilizantes., YUSHUNXIN tiene 3 Consejos para eliminar rápidamente el agua del estiércol de vaca para su referencia..

Consejo 1. Uso de una máquina deshidratadora de prensa para secar rápidamente estiércol de vaca con alto contenido de humedad

Si quieres secar el estiércol de vaca rápidamente, es recomendable utilizar un deshidratador de prensa de estiércol antes del secado. Especialmente cuando tu material es estiércol fresco de vaca., que tiene una humedad sobre 50%. Por una cosa, De hecho, la máquina puede eliminar rápidamente el exceso de humedad del estiércol de vaca.. Después de deshidratar, El contenido de agua del estiércol de vaca puede reducirse a 30%. por otro, El equipo de deshidratación de estiércol utiliza principalmente la fuerza de presión física para separar los desechos sólidos del ganado del líquido.. No se necesita combustible, para que puedas secar el estiércol de vaca rápidamente y a bajo costo.

| Equipo | deshidratador de estiércol |

|---|---|

| Capacidad | 1-4m3/hora |

| Alimentación de humedad | 50%-90% |

| Descarga de humedad | 30%-40% |

| Material de la pantalla | acero inoxidable |

Consejo 2. Trituración de estiércol de vaca para secar partículas más pequeñas rápidamente

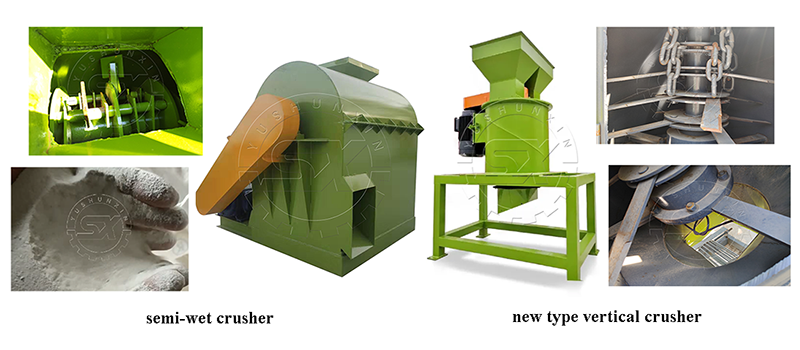

Además, Puede optar por triturar los desechos de la granja de vacas hasta convertirlos en un polvo fino antes de secarlos.. Cuanto menor sea el tamaño de las partículas, cuanto mayor sea el área de contacto del aire, cuanto más rápido se seca el estiércol de vaca. Aquí, YUSHUNXIN puede proporcionar trituradoras profesionales para ti. Trituradora vertical de abonos orgánicos y trituradora de material semihúmedo. El primero está diseñado para la eliminación de estiércol de vaca a pequeña escala.. Su salida máxima es 15 t/h. Además, sin pantalla, sin bloqueo. Mientras que este último es adecuado para la fabricación de estiércol en polvo de vaca a pequeña escala.. Incluso tiene un modelo con 1 t/h de capacidad. Además, El tamaño de las partículas del polvo de estiércol de vaca triturado es menor que el 50 mallas.

| Equipo | Trituradora de estiércol de vaca |

|---|---|

| Capacidad | 1-15 t/h |

| Alimentación de humedad | 25%-50% |

| Tamaño de descarga | 50 mallas |

| Material del equipo | acero carbono Q235 |

Consejo 3. Secado adicional del estiércol de vaca mediante secador rotativo de aire caliente

cuando desee secar aún más los excrementos de vaca con 10%-30% humedad, puedes usar nuestro secador rotatorio directamente. La máquina emplea el método de secado con aire caliente.. en este proceso, 300℃ el aire caliente puede crear una 60 ℃ ambiente de secado del estiércol de ganado dentro del tambor giratorio. Con el tambor de la secadora girando, el estiércol de vaca se puede secar de manera uniforme y rápida. ¿Qué es más?, puedes usar aceite, gas, pellets de biomasa, etc. como combustible para que el estiércol de vaca se seque libremente.

| Equipo | Secador rotatorio |

|---|---|

| Capacidad | 1-20 t/h |

| Alimentación de humedad | 10%-30% |

| Descarga de humedad | 1%-10% |

| Temperatura de secado | 60 ℃ |

¿Existe otro método utilizado para secar los desechos del ganado??

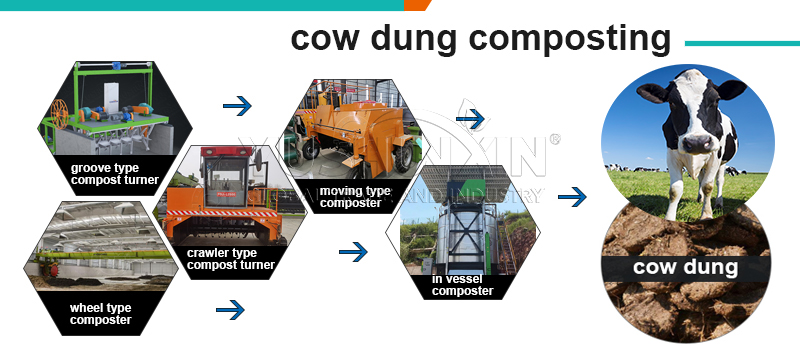

Para 40%-60% humedad secado de estiércol de vaca, También puedes optar por comprar una máquina de compost.. La máquina girará y mezclará para acelerar el compostaje de desechos de vaca. en este proceso, La circulación de aire alrededor del estiércol aumentará.. Y la temperatura del material aumentará para evaporar el agua en los desechos lácteos.. Después del compostaje, La humedad del estiércol de vaca también puede reducirse a 30%. Al mismo tiempo, Puedes convertir la basura del ganado en fertilizante comercial..

| Equipo | Máquina de compostaje |

|---|---|

| Capacidad | 1-20 t/h |

| Alimentación de humedad | 40%-60% |

| Descarga de humedad | 30%-40% |

| Tiempo de compostaje | 15-20 días |

Próximo, Puedes optar por convertir el estiércol de vaca seco en fertilizante o combustible según tus necesidades.. Además, También podemos ofrecerle muchos otros máquinas para la gestión de residuos vacunos y elaboración de abonos orgánicos con estiércol de vaca. Como, granuladores de estiércol de vaca, sistema de embalaje de fertilizantes, etc..