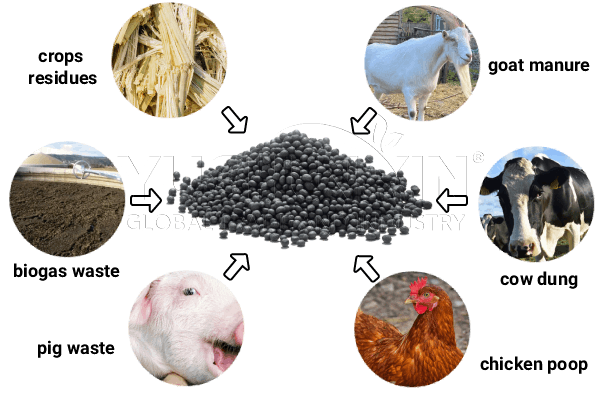

La máquina granuladora de fertilizantes es una parte importante de la línea de producción de fertilizantes orgánicos y compuestos.. Porque puede pulverizar materiales rápidamente para convertirlos en gránulos de fertilizante.. Y el fertilizante granulado tiene características de fácil transporte., almacenamiento y efecto prolongado, que le ayudan a obtener más beneficios del negocio de producción de fertilizantes. como un fabricante profesional de equipos de fertilizantes por casi 20 años, YUSHUNXIIN ha desarrollado varios tipos de máquinas granuladoras de fertilizantes para su elección.. Pueden satisfacer plenamente sus necesidades de fabricación de pellets orgánicos y NPK con 1-30 t/h de capacidad, 1-10 mm de tamaño, etc..

Parámetros principales

- Capacidad: 1-30 T/H

- Tamaño de gránulo: 1-10 milímetros

- Forma de gránulo: bola redonda, bola plana, columna. etc.

- Tasa de granulación: 90%-95%

- Precio del equipo: $3,000-$70,000

- Material del equipo: Acero carbono, Aleación (Personalizado)

- Solicitud: estiércol animal, residuo de biogás, Gránulos NPK, Granulado de fertilizante fosfatado, etc.

Arriba 6 Tipos de máquinas granuladoras de fertilizantes populares para su elección.

En general, YUSHUNXIN tiene 6 Tipos de máquinas granuladoras de fertilizantes a la venta para su elección.. Pueden satisfacer plenamente sus necesidades de fabricación de pellets de fertilizantes a pequeña y gran escala., 1-10 mm de tamaño, presupuesto bajo o alto, etc..

| Equipo | Capacidad (T/H) | Tamaño de gránulo (milímetros) | Humedad de alimentación | Solicitud |

|---|---|---|---|---|

| Peletizador de disco | 1-6 | 1-8 | 20%-40% | Orgánico, Compuesto |

| Granulador de tambor rotatorio | 1-30 | 3-6 | 20%-40% | Orgánico, Compuesto |

| Granulador de doble rodillo | 1-4 | 3-10 | <15% | Orgánico, Compuesto |

| Granulador de fertilizante orgánico de nuevo tipo | 1-8 | 2-5 | 20%-40% | Orgánico |

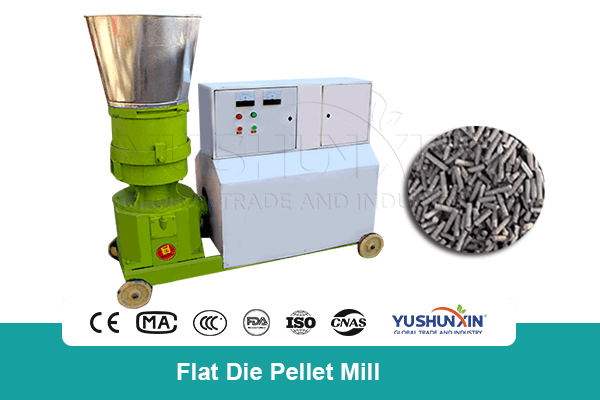

| Molino de pellets de matriz plana | 1-2.5 | 1-10 | <15% | Orgánico |

| Granulador de tambor | 5-8 | 2-5 | 20%-40% | Compuesto Orgánico |

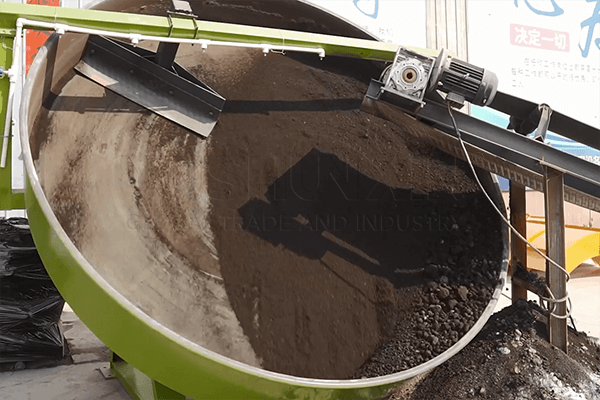

Arriba 1: Peletizadora de bandeja (granulador de disco) para granulación de fertilizantes a pequeña escala

Para la fabricación de gránulos de fertilizantes a pequeña escala, Muchos fabricantes de fertilizantes prefieren comprar un peletizadora de disco.

- Por una cosa, La máquina es una máquina de fácil operación para fabricar gránulos de fertilizante.. Sólo con la rotación del disco y añadiendo agua., Puede convertir el fertilizante en polvo en gránulos en varios minutos.. La capacidad máxima es 6 t/h.

- por otro, La tasa de granulación de este tipo de granulador puede alcanzar más de 93%. Tanto para granulación de fertilizantes orgánicos como para granulación de fertilizantes compuestos..

- ¿Qué es más?, Puede cumplir plenamente con sus requisitos para 1-8 mm producción de gránulos de fertilizante. Puede regular libremente el tamaño de los gránulos de fertilizante controlando la humedad del material y planificando el ángulo de inclinación.. menos agua, tamaño más pequeño; mucha agua, tamaño más grande. Pendiente pronunciada, tamaño más pequeño; pendiente lenta, gránulos más grandes.

Consulta el sistema de granulación de fertilizantes en discos.!

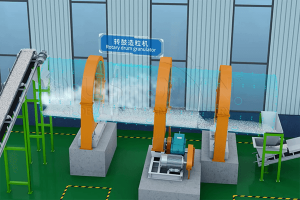

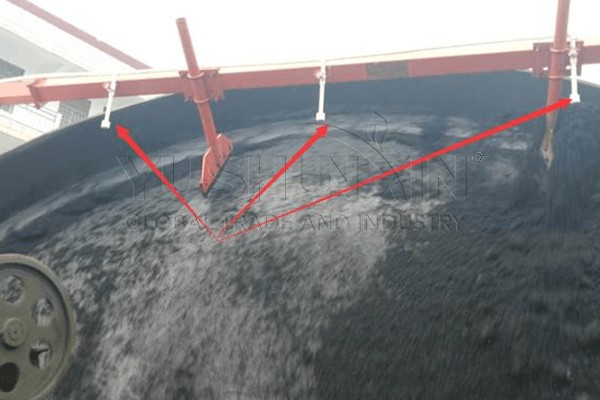

Arriba 2: Granulador de tambor rotatorio para planta de granulación de fertilizantes industriales a gran escala

Granulador de tambor Es uno de los equipos clave a gran escala. Instalación de planta de granulación de fertilizantes industriales..

- Por un lado, Con diseño de tambor giratorio y rociador de agua., La máquina puede satisfacer completamente sus necesidades para producir pellets de fertilizante entre 1 t/h y 30 t/h. Y se acabó la tasa de granulación de fertilizantes. 90%.

- Por otro lado, durante más tiempo produzca gránulos de fertilizantes orgánicos y compuestos para usted, le añadimos el revestimiento de goma y le pegamos agujeros de prevención. Pueden reducir la erosión del equipo durante el procesamiento de fertilizantes..

Por supuesto, La máquina también es adecuada para proyectos de granulación de fertilizantes orgánicos y químicos..

Obtenga más información sobre la granulación rotativa de fertilizantes!

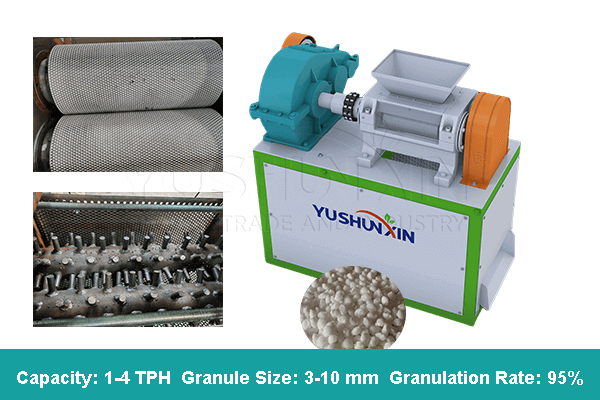

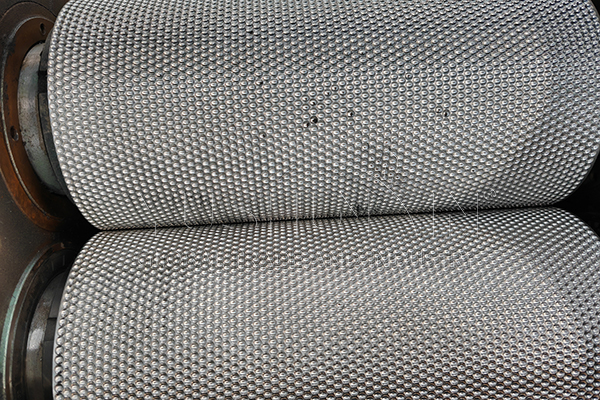

Arriba 3: Granulador de extrusión de doble rodillo para una producción más rápida de pellets de fertilizante

Para una granulación más rápida de fertilizantes orgánicos y NPK, diseñamos especialmente granulador de extrusión de doble rodillo en venta.

- Como sugiere el nombre, La máquina granuladora de fertilizantes depende de la fuerza de extrusión entre los rodillos para presionar el polvo de fertilizante en gránulos.. Una vez presionado, se puede conseguir abono granulado de alta dureza. Al mismo tiempo, la tasa de granulación puede alcanzar 95%.

- Según sus requisitos para la forma de rótula en este granulador, La forma de la hoja enrollable puede ser como una almohada., semicírculo, palo, píldora, nuez, bola plana y barra cuadrada, etc..

¿Cuál es el costo de la línea de granulación de doble rodillo??

Arriba 4: Máquina granuladora de fertilizantes orgánicos de nuevo tipo de alta tasa de granulación

Pero, si prefiere producir pellets de fertilizante con mayor granulación, te recomendamos comprar el Nuevo tipo de máquina de pellets para fertilizantes orgánicos en YUSHUNXIN.

- Además utiliza líquido como aglutinante., La máquina granuladora de fertilizantes adopta un diseño de dientes agitadores para acelerar la granulación de fertilizantes. Cuando los materiales en polvo se envían en este granulador, Los dientes agitadores comienzan a girar a alta velocidad.. Luego, bajo la acción de una fuerza mecánica giratoria de alta velocidad y la fuerza aerodinámica resultante, La materia prima logrará el proceso de mezcla., granular, pelota, densificación y de gránulos de fertilizantes orgánicos y pellets de fertilizantes químicos rápidamente.

- al mismo, la tasa de granulación puede alcanzar 97%. Además, También tiene ventajas de fabricación de pellets de fertilizantes de alta dureza y menor contaminación por polvo..

¿Hay un vídeo sobre la fabricación de pellets de fertilizante orgánico de nuevo tipo??

Arriba 5: Venta de fábrica de pellets de matriz plana económica

Además, nosotros diseñamos granulador de matriz plana para la preparación económica de pellets de fertilizante.

- Puño, tiene un precio económico. Con 1-2.5 t/h de producción, solo necesitas prepararte $3,000-$6,000 Para comprar una peletizadora de fertilizantes de matriz plana.. Al mismo tiempo, La máquina tiene características de fácil operación., menor ocupación del área, etc..

- Entonces, La máquina también es adecuada para la fabricación de pellets de diversos materiales.. Como la fabricación de pellets de fertilizantes orgánicos., producción de pellets de pienso, prensado de briquetas de biocarbón, fabricación de pellets de madera, etc..

Puede proceso de granulador de matriz plana 5 t/h de fertilizante?

Arriba 5: Granulador batidor de tambor rotatorio dos en uno

Finalmente, para aquellos que prefieren producir gránulos de fertilizantes de bolas redondas con una alta tasa de granulación, puedes comprar un Granulador de batido de tambor rotatorio. Como sugiere el nombre, Combina los métodos de granulación con dientes agitadores y tambor giratorio.. Por lo tanto, La máquina granuladora de fertilizantes es beneficiosa para la granulación de fertilizantes en aspectos.:

- Mayor tasa de granulación de fertilizantes: Bajo la acción de agitar los dientes, la fuerza mecánica y la cohesión del agua., La tasa de producción de pellets de fertilizante puede alcanzar 97%.

- Mientras, con ayuda del tambor giratorio, Los pellets de fertilizante granulado tienen una forma más redondeada y una superficie lisa.. Entonces, tiene un valor más alto y le ayuda a obtener más ganancias.

Obtenga su plan personalizado de fabricación de pellets de fertilizante!

¿Cuáles son los precios de las peletizadoras de fertilizantes??

Cuándo comprar una máquina para fabricar gránulos de fertilizante, ya sea para la fabricación de fertilizantes orgánicos o la preparación de fertilizantes compuestos, debemos centrarnos en el precio. Como fábrica fuente de granuladores de fertilizantes., YUSHUNXIN puede ofrecerle un precio favorable. En general, los precios de lo anterior 6 Los tipos de granuladoras de fertilizantes son los siguientes.:

- Precio del peletizador de disco : $3,500-$15,000

- Costo del granulador de tambor rotatorio: $8,000-$90,000

- Precio de la máquina extrusora de doble rodillo: $4,000-$13,000

- Costo del granulador de fertilizante orgánico de nuevo tipo:$5,200-$55,000

- Precio de la fábrica de pellets Plat Die: $3,000-$6,000

- Costo del granulador de batido de tambor rotatorio: $20,000-$30,000

Los precios del granulador de fertilizantes anteriores son de referencia.. Porque fluctuará con los detalles del diseño del equipo., uso de materiales, tiempo, tipo de cambio, etc.. Puede contactarnos ahora para obtener una cotización de máquinas granuladoras de fertilizantes..

Cómo hacer que los gránulos de fertilizante sean más redondeados.?

Entre las máquinas granuladoras de fertilizantes anteriores., el granulador de prensa de rodillos, La fábrica de pellets de matriz plana producirá pellets de fertilizantes en forma de columna y bola plana para usted.. ¿Existe una máquina para hacer que las partículas de fertilizante sean más redondeadas y de tamaño uniforme?? Aquí, máquina pulidora de fertilizantes está diseñado para ti. Con la ayuda de esta máquina, La tasa de granulación será mayor y no se crearán materiales de retorno.. Entonces, Hace que su proceso de granulación de fertilizantes orgánicos y compuestos sea más eficaz.

¿Cuál es el contenido de humedad de las materias primas antes de la granulación del fertilizante??

El contenido de humedad de las materias primas antes del proceso de granulación del fertilizante es un factor crítico que influye significativamente en la eficiencia y calidad de los gránulos de fertilizante finales.. Si el contenido de humedad es demasiado bajo , Es posible que los materiales en polvo no se unan eficazmente durante el proceso de granulación., resultando en debilidad, gránulos quebradizos que pueden romperse fácilmente. En cambio, si el contenido de humedad es demasiado alto, Los materiales pueden volverse demasiado pegajosos y formar grandes, grupos desiguales, lo que puede obstruir la máquina granuladora de fertilizantes y provocar una mala calidad de la granulación. Entonces, ¿Cuál es la mejor humedad para la fabricación de gránulos de fertilizante?? Para esto, debe considerar que el método de granulación que adopta es húmedo o seco.

fertilizante húmedo granulación humedad

Cuando compras un máquina de granulación húmeda para la fabricación de pellets de fertilizantes orgánicos o compuestos, es necesario ajustar la humedad del material a 20%-40% antes de granular. Incluye peletizadora de bandeja, Granulador de tambor rotativo y granulador de fertilizante orgánico de nuevo tipo.

Equipo de granulación en seco Material de alimentación Contenido de agua.

Pero, para equipo de granulación seca laboral, Requiere un contenido de agua del material de alimentación inferior a 20%. Porque utiliza principalmente la fuerza de extrusión del rodillo para granular fertilizantes orgánicos y compuestos en polvo..

Aquí, YUSHUNXIN puede ofrecer una máquina deshidratadora de fertilizantes y una secadora para reducir la humedad y granuladores con dispositivo rociador para agregar agua..

Obtenga ahora su propio plan de granulación de fertilizantes!

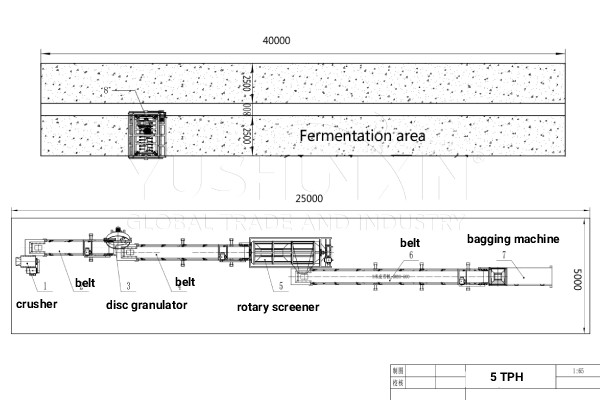

¿Pueden ofrecer una línea completa de granulación de fertilizantes??

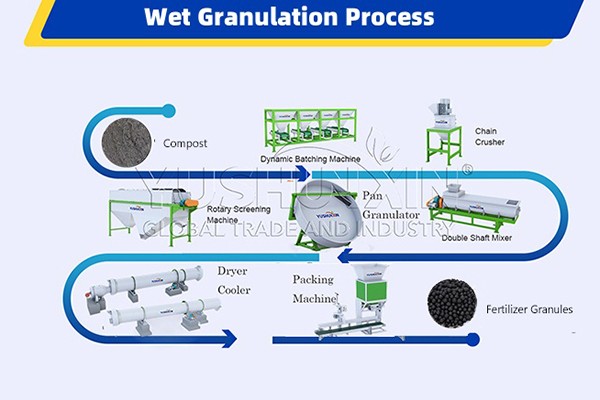

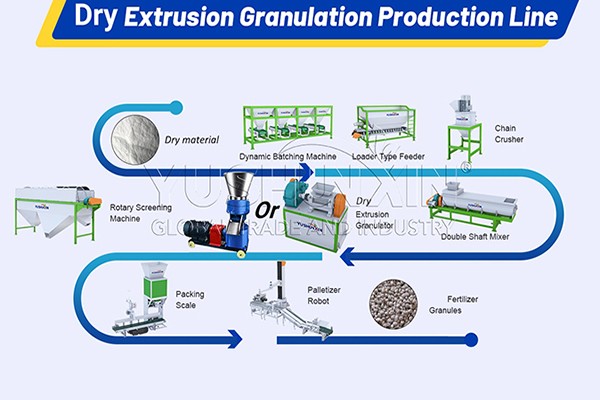

Por supuesto. Generalmente, Una línea completa de granulación de fertilizantes incluye principalmente una máquina dosificadora de materiales., trituradora, mezclador, granular, evaluador, secadora, enfriador, recubridor, y equipos de embalaje. Cada pieza está diseñada para un funcionamiento estable y una producción eficiente de fertilizantes.. Si planea iniciar o actualizar su proyecto de fabricación de fertilizantes, Podemos proporcionar una línea completa de granulación de fertilizantes con un diseño personalizado según sus materias primas., capacidad, y presupuesto, etc.. Por ejemplo,

Líneas de granulación de fertilizantes orgánicos y compuestos.

cuando tu procesar pellets de fertilizantes con residuos orgánicos, como estiércol de pollo, estiércol de vaca, residuos de biogás o compost , Agregaremos una máquina deshidratadora y volteadores de compostaje para usted..

O producir fertilizantes compuestos de NPK, SSP, o gránulos de zeolita, no hay necesidad de equipos de compostaje y deshidratación.

Instalación de plantas de fertilizantes granulares a pequeña y gran escala.

Entonces, como se mencionó anteriormente, para la configuración de una planta de granulación de fertilizantes a pequeña escala, ambos línea de granulación de discos y sistema de granulación con prensa de rodillos son la elección ideal.

Cuando se trata de producción de fertilizantes granulados a gran escala, el granulación de tambor rotatorio Se recomienda la línea. Además, También hay disco personalizado., Planes de granulación con prensa de rodillos para operaciones a gran escala..

Soluciones para tecnologías de granulación de fertilizantes húmedos y secos

Además, en términos del método de granulación, También existen soluciones personalizadas de fabricación de fertilizantes granulados.. Para granulación húmeda, que se procesa con 20%-40% de humedad, Puede elegir un plan de fabricación de gránulos con tambor giratorio o sistemas de peletización en bandeja..

Mientras tanto, para granulación en seco, El contenido de agua del material debe estar por debajo. 20%, El proceso de extrusión de doble rodillo está aquí para usted..

Si tiene algún otro requisito para la configuración de su línea de fabricación de pellets de fertilizante, Bienvenido a contactarnos para personalizarlo..

Obtenga ahora su propio plan de granulación de fertilizantes!

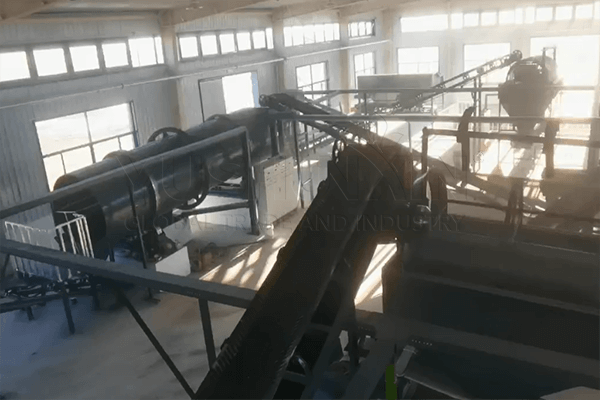

Proyectos terminados de producción de gránulos de fertilizantes en todo el mundo.

Siempre que necesite plantas para fabricar gránulos de fertilizante terminados con máquinas YUSHUNXIN, Hay algunos casos para su referencia.. Por ejemplo, Línea de granulación de estiércol de vaca en Ecuador, $50,000 Línea de granulación de biofertilizantes en Vietnam, Fabricación de pellets SPP en Egipto, Fabricación de gránulos para derretir hielo en Corea, etc.. Nuestras máquinas granuladoras de fertilizantes se han vendido a todo el mundo y obtienen buenos comentarios..

Además, combinar con trituradora, mezclador, evaluador, secadora, colador, maquina empacadora, puedes configurar un línea de granulación de fertilizantes para una mejor producción de pellets de fertilizante. Bienvenido a contactarnos ahora!