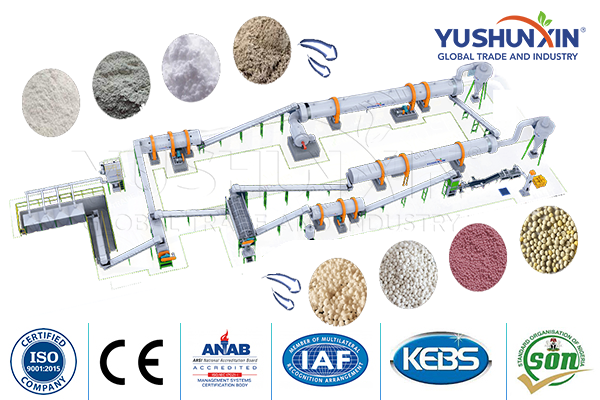

Compound fertilizer production line, as the name implies, es una línea de producción ampliamente utilizada en la fabricación de fertilizantes químicos. Línea de producción de fertilizantes compuestos., as the name implies, is a production line widely used in making chemical fertilizer. Suele contener equipos de dosificación., aplastante, mezclando, granulación, el secado, enfriamiento, revestimiento, embolsado y accesorios. Pueden producir fertilizantes complejos con diferentes concentraciones y tipos.. Como la fabricación de gránulos de fertilizantes compuestos NPK y la producción de fertilizantes NPK mezclados.. Además, según necesidad, YUSHUNXIN Le ofreceremos soluciones personalizadas y máquinas.. Incluyendo el diseño de la fábrica de fertilizantes compuestos granulares azules npk, Línea de producción de fertilizantes de roca fosfórica., etc..

Parámetros principales

- capacidad: 1-20 t/h

- Material del equipo: Acero al carbono Q235/Aleación

- Voltaje: 220v/380v/415v/440v/480v(50Hz/60Hz)

- Forma del material químico: polvo o gránulo

- Tipos: Fabricación de fertilizantes NPK, producción de fertilizantes mezclados a granel, Fabricación de fertilizantes SSP, etc.

- Solicitud: Urea, cloruro amónico, superfosfato,potassium chloride, etc.

como producir 15-15-15 Fertilizante compuesto NPK?

¿Cuáles son las materias primas contenidas en la fabricación de fertilizantes compuestos??

En general, para procesar fertilizantes compuestos, Su material principal debe contener dos o más elementos nutrientes en nitrógeno., fósforo y potasio. Entonces, ¿Qué tipo de material contiene estos elementos?? Hay algunos para tu referencia..

Nitrógeno es el principal responsable de promover el crecimiento de ramas y hojas.. Porque puede mejorar la capacidad de las plantas para absorber nutrientes.. Si quieres hacer fertilizante compuesto con rico elemento nitrógeno.. puedes usar urea, cloruro amónico, ammonium sulfate, nitrato de amonio y nitrato de calcio como materiales.

Fosfato juega un papel importante en la floración y fructificación.. Si quieres aumentar su contenido a la hora de preparar abono compuesto. Fosfato monoamónico(MAPA), fosfato diamónico (SALTO), superfosfato triple (TSP) y superfosfato (SSP) son excelentes opciones para ti.

Potasio Es esencial para promover el desarrollo de los rizomas.. Y mejorar la capacidad de los cultivos para adaptarse a los cambios de temperatura y resistir plagas y enfermedades.. Luego cloruro de potasio (FREGAR), sulfato de potasio (COMPENSACIÓN), El carbonato de potasio y las cenizas vegetales son la clave para la producción de fertilizantes complejos con potasio..

Existen diversos materiales para la elaboración de fertilizantes compuestos. Puedes elegir según tus necesidades.. Como los complejos procesos de elaboración de fertilizantes.. Para diferentes procesos, necesitas preparar materiales con diferentes formas. Powder or granule?

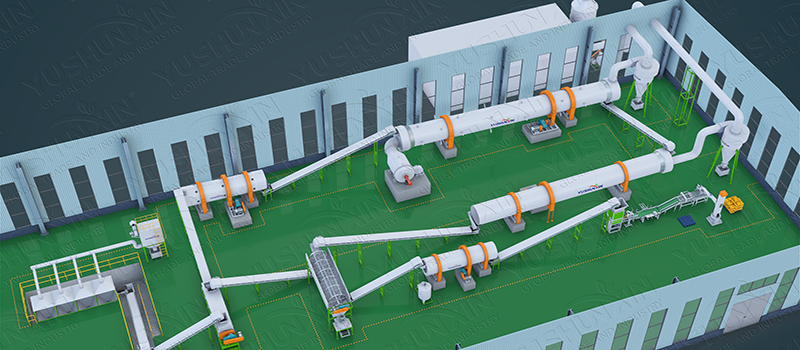

2 Líneas de producción de fertilizantes compuestos más vendidas en YUSHUNXIN

Para satisfacer las necesidades de producción de fertilizantes compuestos., Nuestros ingenieros diseñan una variedad de sistemas de producción de fertilizantes químicos.. entre ellos, la siguiente 2 Los tipos de líneas de producción de fertilizantes compuestos son nuestros productos más vendidos.. Están diseñados para negocios de fertilizantes compuestos de alta rentabilidad y para la instalación de plantas de fertilizantes complejos de rápido retorno, respectivamente.. Para materiales, uno usa polvo y el otro adopta pellets.

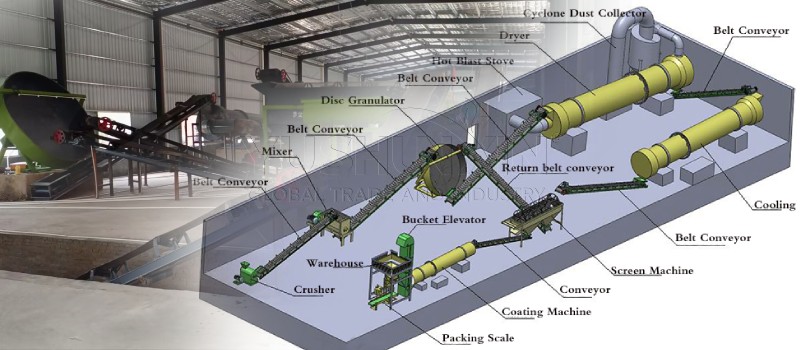

Línea de granulación de fertilizantes NPK a la venta

Si eres propenso a hacer fertilizante compuesto granular, te recomendaremos Línea de producción de fertilizantes NPK to you. Como el proceso anterior, producirá gránulos de fertilizante compuesto NPK a partir de polvo para usted. Además, Podemos ofrecerle un plan personalizado de elaboración de fertilizantes compuestos según sus necesidades., como capacidad.

- Cuando planeas hacer 1-6 toneladas de gránulos de fertilizante químico por hora, el línea de fabricación de pellets de disco es la mejor opción. Precio económico y más. 93% tasa de granulación.

- Pero si desea ampliar la compleja escala de la planta de fertilizantes, Puedes reemplazar el granulador de bandeja con peletizadora de tambor rotatorio, que tiene una gran producción de 1-30 t/h. Para que pueda satisfacer plenamente sus necesidades, si planeas construir un pequeño, planta de fertilizantes compuestos mediana o grande.

Consulte la línea de granulación de fertilizantes compuestos NPK!

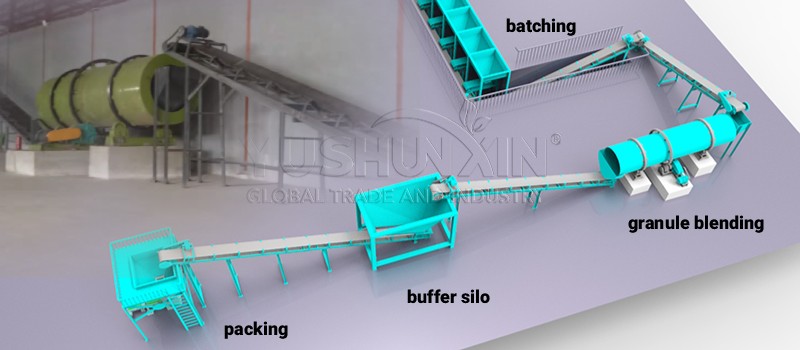

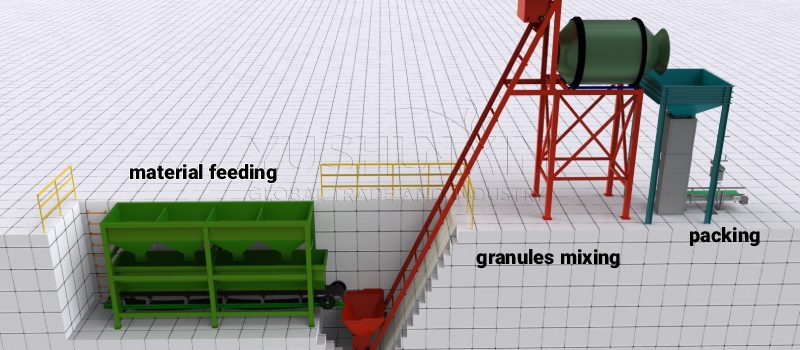

Línea de producción de fertilizantes BB a la venta

Si planeas hacer fertilizante compuesto granular, pero tu presupuesto no es suficiente. Puedes elegir esto Línea de producción de fertilizantes BB, que también se conoce como línea de fabricación de fertilizantes de mezcla a granel. Sólo necesita agregar varios fertilizantes individuales o fertilizantes compuestos a los contenedores de dosificación.. Luego, después de que la batidora los mezcle uniformemente., puedes empaquetar el fertilizante. Sólo hay una fuerza mecánica., pero no ocurre ninguna reacción química. Por lo tanto, la línea de producción de fertilizantes de mezcla a granel tiene menos pasos de proceso y reduce en gran medida el costo de producción.. Consta de cuatro tipos de equipos fertilizantes.. Including batching machine, transportador, mezcladora y envasadora. Sólo necesitas prepararte $10,000-$90,000 Presupuesto para la fabricación de fertilizantes NPK. en 1-20 Capacidad T/H.

Obtenga la línea de producción de fertilizantes BB de inmediato!

Cómo convertir las materias primas en el fertilizante complejo que necesitas?

Si quieres convertir materia prima en fertilizante de alta calidad, necesitas procesarlo varias veces. Como fabricante profesional de equipos de fertilizantes., Shunxin puede proporcionarle el equipo de fertilización adecuado para cada procedimiento.. El siguiente es el procedimiento de producción más completo de fertilizantes compuestos..

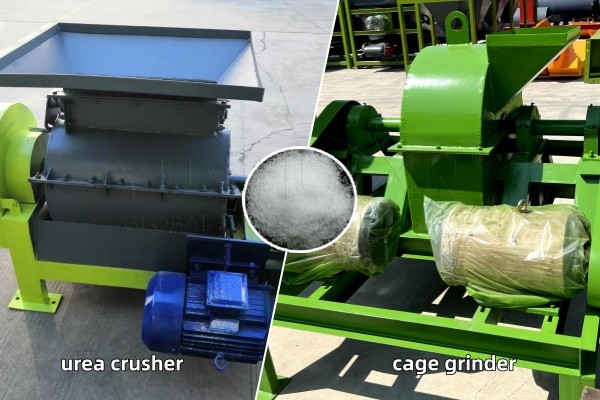

Aplastante

Antes de producir fertilizante compuesto, Necesitas convertir todos los materiales en polvo.. Porque es conveniente para el posterior procesamiento por lotes y mezclas.. Entonces el trituradora de fertilizante Desempeña un papel importante en la producción de fertilizantes químicos de alta calidad.. La trituradora de jaula y la trituradora de cadena son adecuadas para triturar materiales fertilizantes compuestos..

Batching

El fertilizante compuesto se produce especialmente para complementar los nutrientes que faltan en el crecimiento de las plantas.. Entonces necesitas hacerlo en cierta proporción.. El procesamiento por lotes es el proceso para ajustar la proporción.. Durante este proceso, hay estática máquina dosificadora y equipo de procesamiento por lotes automático dinámico para su elección. Tienen un alto grado de automatización y pueden ahorrarle mucho tiempo y costos de producción..

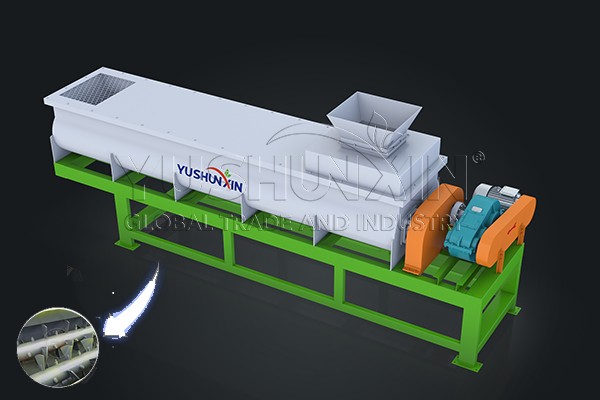

Mezclando

Entonces necesitas mezclar completamente los materiales.. Es el paso clave para hacer un fertilizante compuesto uniforme.. Para esto, te recomendamos elegir batidora horizontal o batidora de discos. El primero puede ayudarlo a mezclar diferentes materiales químicos de manera uniforme y efectiva y el segundo puede ayudarlo a reducir el costo de la fabricación de fertilizantes compuestos..

Granulación

Si quieres mejorar aún más el fertilizante compuesto, convertirlo en gránulos es una excelente opción. Después de granular, El área de contacto entre fertilizantes se hará más pequeña., lo que hace que no sea fácil de pegar. Por eso es conveniente para el almacenamiento y el transporte.. entre nuestros granuladores de fertilizantes químicos, granulador de bandeja, Los peletizadores de tambor giratorio son más adecuados para usar método de granulación húmeda. y el granulación de doble rodillo is an ideal choice, si quieres usar el método de granulación seca.

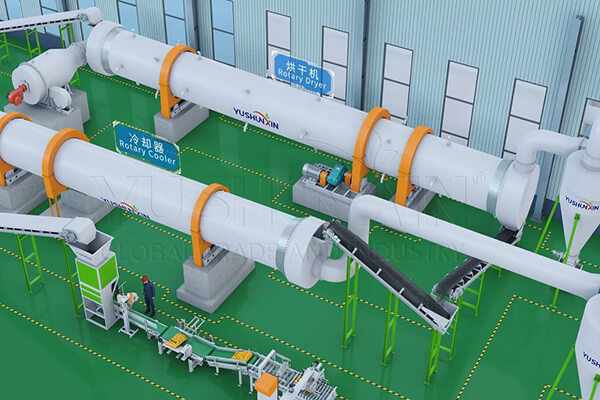

Secado y enfriamiento

El contenido excesivo de humedad no favorece el almacenamiento y uso de fertilizantes.. Si el contenido de humedad del fertilizante es superior a 14%, el proceso de secado es inevitable. Luego después del secado, El enfriamiento puede eliminar el agua de la superficie de los pellets., y bajar la temperatura.

Cribado

Durante este proceso, es necesario diferenciar entre fertilizantes calificados y no calificados. Luego transfiera el fertilizante calificado al siguiente procedimiento., y los no calificados para regranular. Máquina de cribado rotativa puede ayudarte a completar la tarea perfectamente.

Coating

Formará una película protectora sobre la superficie del fertilizante químico.. La película protectora puede aislar el aire., lo que puede hacer que los gránulos se vuelvan fáciles de pegar nuevamente. Si desea agregar una película protectora a sus gránulos químicos, puedes comprar nuestro equipo de recubrimiento de tambor.

Embalaje

Embalaje Es el último procedimiento de toda la línea de producción de fertilizantes compuestos.. It is dispensable if you make fertilizer for your own use. But if you want to sell it to others, it can improve the competitiveness of your fertilizer products.

Cómo iniciar un negocio de fertilizantes compuestos?

A medida que crece la demanda de fertilizantes compuestos, Cada vez más personas o empresas pasan a producir fertilizantes químicos.. ¿Sabe qué debe considerar si desea iniciar un negocio de fertilizantes compuestos?? There are some tips for your reference:

Haga un plan presupuestario para la elaboración de fertilizantes compuestos.

Se basa en su encuesta e investigación sobre la industria de fertilizantes compuestos.. Este plan debe incluir su presupuesto total., así como su presupuesto para cada proyecto. Como terrenos industriales, equipo de fertilizantes, materials, etc.

Decide tu químico materiales y encontrar un proveedor estable

Sólo después de determinar el tipo de materias primas., puedes elegir el equipo adecuado. Con una fuente estable de materias primas, puedes producir fertilizantes consistentemente. Garantiza que tengas suficientes productos para vender..

Elija un lugar para construir el taller para la fábrica de fertilizantes compuestos.

Debe estar lejos de la zona de vida y trabajo de la población.. Porque habrá cierta contaminación en el proceso de producción de fertilizantes compuestos.. Es necesario evitar que esta contaminación afecte la vida de los habitantes.. Y el taller debe estar ubicado en un lugar de fácil acceso.. Es beneficioso para la venta y transporte de fertilizantes compuestos..

Seleccione un fabricante confiable de equipos de fertilizantes complejos

No sólo puede proporcionarle equipos de fertilizantes compuestos de alta calidad., pero también te ofrecemos muchos consejos útiles.. SX tiene 20 Años de experiencia en la producción de equipos de fertilizantes compuestos.. Es una opción óptima para ti..

Otros artículos sobre la elaboración de fertilizantes compuestos.

Además, si quieres aprender más sobre fabricación de fertilizantes orgánicos, También podemos ofrecerle las mejores soluciones.. Bienvenido a contactarnos para iniciar su complejo. & Negocio de fabricación de fertilizantes orgánicos con éxito..