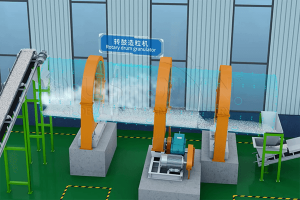

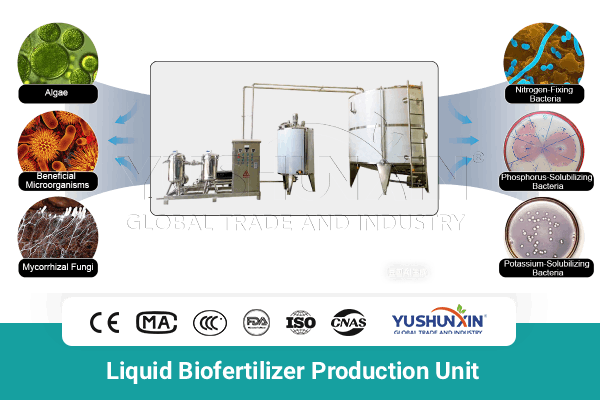

Setting up a liquid biofertilizer production unit has become one of the most profitable directions for many businesses. ثم, how to process finished liquid fertilizer into bio type? How to make liquid biofertilizer from manure waste? There are customized solutions and professional equip for you liquid bio fertilizer making projects. They offer you the best bacteria survival, no impurities and economical costs. Come to see them now!

المعلمات الرئيسية

- سعة: 1-20 الهيدروكربونات النفطية في الساعة

- يكلف: $20,000-$600,000 (reference)

- مواد المعدات: الفولاذ المقاوم للصدأ (customized)

- الجهد االكهربى: 220فولت/380 فولت/415 فولت/440 فولت/480 فولت(50هرتز/60 هرتز)

- مواد التطبيق: روث البقر, أنبوب الدجاج, biogas digestate, finished liquid fertilizer, إلخ

How to process standard liquid fertilizer into the bio type one?

To produce liquid biological fertilizer on the basic of the general one is finished, there is a liquid biofertilizer production unit of 5 parts for you. أنه يحتوي على:

Feeding and batching system of powder and liquid

عادة, the required liquid biofertilizer making starts with accurately materials feeding with target proportion.

- For liquid type, such as general liquid fertilizer or liquid additives. there is flow pump for precisely feeding.

- في نفس الوقت, for powder functional bacteria agent adding, you can use a screw type conveyor.

After fed into batching tank, the inside shaft will mixing the liquid fertilizer with microorganism agent evenly until dissolving thoroughly.

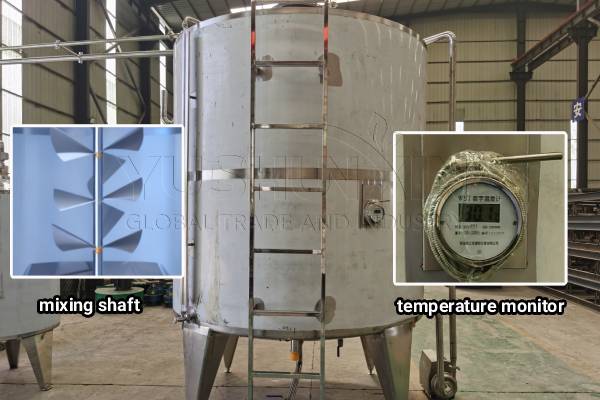

Chelation tanks with heating and mixing

These chelation tanks of الفولاذ المقاوم للصدأ are the core reactors of the liquid biofertilizer production unit. They are responsible for chelating basic liquid fertilizer and fed functional bacteria, so that the latter will dissolving fully into the former. To help you finish the liquid bio fertilizer production faster, YUSHUNXIN especially design the liquid reators with heating system and mixing shaft inside. For liquid fertilizer making with microorganisms, it is important to control the temperature in chelation

Filtration system for impurities removing

ثم, to produce more clear biological liquid fertilizer, we need to filter the liquid after chelation. This is beneficial for removing impurities, undissolved residues, and unwanted microorganisms. Because a clean solution improves the survival rate of beneficial bacteria, this filtration step is important for the stability of biofertilizer shelf life. لهذا, you can adopt the ultrafiltration membrane system, which filtration precision can reach 0.1–0.2 μm.

Storage tanks of liquid fertilizer

White or semi-transparent tanks are ideal because workers can directly observe liquid levels through the tank wall. This design also prevents overfilling or unexpected downtime, and many customers prefer these tanks for visual management.

Automatic liquid filling machine

The YUSHUNXIN liquid biofertilizer production unit usually ends with automatic filling systems that offer: Quantitative filling, capping, وضع العلامات, إلخ. With PLC control, these machines run smoothly with minimal labor. And because produced liquid biological fertilizers are often sold in 1–20 packages, automated filling greatly improves efficiency for commercial manufacturers.

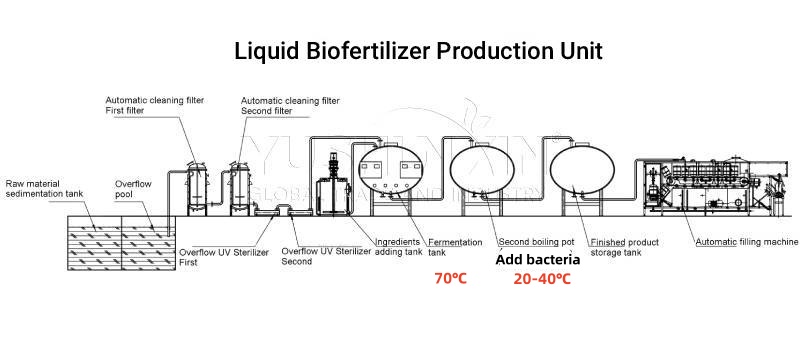

Is There a Liquid Biofertilizer Production Unit for Fresh Cow Dung?

نعم, you can build a liquid biofertilizer production unit using fresh cow dung as your primary raw material. Many animal farms choose this method. Because it not only dispose of cow farm slurry quickly, but also produce liquid fertilizer with a high value. عادة, ل prepare quality organic liquid fertilizer from cow manure, you need a system of follow machines.

- Solid–liquid separation to get liquid materials

- Filters to further remove small particles impurities

- Ultraviolet sterilization device to reduce harmful pathogens

- Liquid Chelation fermentation tanks to deeper kill pathogens and dissolve nutrients

- Secondary chelation with added functional bacteria and dissolving

- Ultrafiltration membrane system for impurities removing again

- Finished product storage tank for ensuring nutrient stability

- Automatic liquid filling machine for liquid cow dung fertilizer filling, covering and labeling

With the liquid biofertilizer production unit, you can process cow urine and slurry waste into quality liquid biofertilizer ranging 1-20 الهيدروكربونات النفطية في الساعة.

Why add functional bacteria during secondary chelation?

This design is to ensure functional bacteria survival most during liquid organic biofertilizer manufacturing process.

During primary chelation, which is to kill harmful pathogens, the temperatures in the liquid fertilizer reactor can reach 60 درجه مئوية. Under the condition, the added microorganisms will be damaged. لذا, you need a secondary chelation in a low temperature (20-40درجه مئوية) to ensures that microbial strains enter the fertilizer in an active state. فضلاً عن ذلك, the secondary chelation also helps beneficial bacteria bond with nutrients, you can produce fertilizer with improved both stability and effect in the field.

Why use an ultrafiltration membrane system after chelation?

After bio liquid fertilizer chelation, you need to filter the fertilizer again. This is the key steps to process liquid fertilizer with clarity and stability. Also, protects the your liquid filling machine from clogging.

هنا, the ultrafiltration membranes system is the best choice. It can remove tiny particles, جراثيم فطرية, and insoluble residues from the produced liquid bio fertilizer while the filtration precision reaches 0.1–0.2 μm. في نفس الوقت, this is an excellent choice to remove harmful pathogens again while ensure beneficial microorganisms survival.

How much does a liquid biofertilizer production unit Cost?

The cost of setting up a liquid biofertilizer production unit depends on scale, الأتمتة, and filtration level. General ranges of the above simple bio liquid fertilizer system from batching to packing are:

- Small-scale (1–5 TPH) bio liquid fertilizer making line cost: $20,000–$100,000

- 5–10 TPH liquid biofertizer production system quotation: $10,000–$300,000

- Large-scale (10–20 TPH) liquid biological fertilizer project equipment investment: $300,000–$600,000

Nearly all YUSHUNXIN equipment in the biological liquid fertilizer manufacturing system mode of stainless steel. And the whole system controlled by the PLC container. وهي, only several workers employment, you can finish the large scale liquid biofertilizer production smoothly.

As the turkey fertilizer equipment manufacturer, YUSHUNIXN can offer you one-stop service from business plan design to installation, welcome to contact us for you own liquid fertilizer production solutions now! Or there are also خط تحبيب الأسمدة, powder fertilizer making systems and various compound fertilizer preparation plant layouts لاختيارك.