As sustainable agriculture gains momentum, investing in an organic fertilizer plant has become an attractive opportunity for entrepreneurs and agribusinesses. But before committing capital, every smart organic fertilizer making plant investor wants to know: How long will it take to become profitable? Pour ça, you need to specially focus on fertilizer equipment cost. Because it often makes up the largest share of capital expenditure of organic fertilizer factory setup and plays a critical role in determining profitability. En outre, YUSHUNXIN can offer you customized fertilizer making solution with faster investment return, which only takes half to a year.

What is contained in the ROI of an organic fertilizer plant setup?

If you want to know when will an organic fertilizer plant become profitable, you must know the ROI of your organic fertilizer making project.

En général, le ROI = (Net Profit / Total Investment Cost) × 100%. Donc, il y a 4 aspects you need pay attention to:

- Equipment and installation costs (CAPEX)

- Monthly operational expenses (OPEX)

- Production volume and market prices

- Plant efficiency and material availability

Among these, equipment cost is the most significant capital outlay and can greatly impact how quickly the plant becomes profitable.

How much does the organic fertilizer equipment costs?

In a typical organic fertilizer plant setup investment, equipment costs account for 50% à 70% of the total investment. Here’s why:

| Équipement | But | Estimated Cost (USD) |

|---|---|---|

| Composting system | Fermentation (windrow/in-vessel) | $10,000 – $80,000 |

| Crushing and mixing | Prepares raw materials | $8,000 – $50,000 |

| Granulation machine | Pellet makingl(e.g. roller press) | $15,000 – $100,000+ |

| Drying & cooling systems | (if needed) moisture control | $20,000 – $150,000 |

| Dépistage & packaging | Product quality and final packing | $10,000 – $60,000 |

| Automation & conveyors | Material handling and integration | $10,000 – $80,000 |

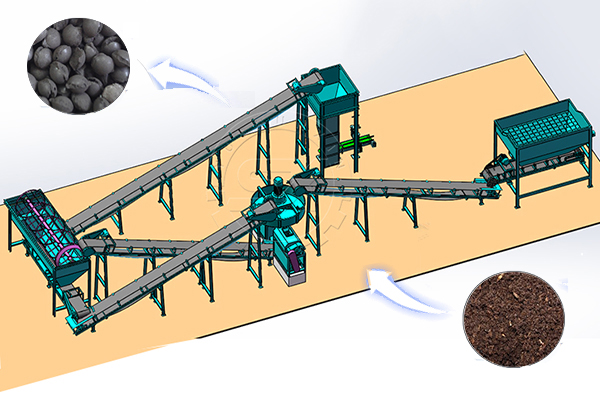

Total organic fertilizer manufacturing equipment price range: $60,000 à $500,000+ depending on scale and automation level. Parmi eux, the organic fertilizer granulation system (often using a roller press pellet machine) typically represents 20–35% of organic fertilizer equipment costs, especially in dry fertilizer granulation plant setups.

Get your organic fertilizer making system quote now!

What is the total investment of an organic fertilizer granulation factory establishing (5 ème)?

Besides industrial organic fertilizer purchasing, we also need to prepare budget for factory land rent or buying, infrastructure building, licensing & permits expense, operational investment, etc. Here, we will takes a 5 t/h capacity one as an example.

| Category | Approximate Cost |

|---|---|

| Land & construction | $50,000 |

| Équipement & installation | $200,000 |

| infrastructure building | $20,000 |

| Licensing & permits | $10,000 |

| Operatioal capital | $30,000 |

| Total | $310,000 |

In this example, equipment represents 65% of total startup costs—a key factor in ROI and long-term success.

How long does the 5 /h organic fertilizer plant became profitable?

Provided you make the organic fertilizer making line work 20 heures par jour, 300 days a year, you produces 3,000 tons/year of organic granules per year. Average, the price of the organic fertilizer granules is at $250/ton. That gives a gross revenue of $750,000/year.

En outre, because the operating expenses of an 5 t/h organic fertilizer making factory is about $250,000/year. Donc, the net profit = $500,000/year. Alors, The payback period = $310,000 ÷ $500,000 ≈ 0.62 années

But more realistically, with marketing, ramp-up time, and unforeseen costs, the typical ROI period is 1–2 years for the small scale organic fertilizer plant setup.

While many factors influence profitability, equipment investment is the cornerstone of an organic fertilizer plant’s ROI. A thoughtful equipment strategy—balancing cost, efficiency, and scalability—can dramatically shorten your payback period and increase long-term gains. Whether you’re launching a small unit or a full-scale facility, knowing where and how to invest in equipment will define your success.