Besides fabriquer de l'engrais solide à partir du fumier de vache, vous pouvez également choisir de jeter les déchets de bouse de vache dans un engrais liquide. Pour ça, nous pouvons vous proposer un plan et des machines de production d'engrais liquide de fumier de vache personnalisés. Ils peuvent pleinement répondre à vos besoins pour fabriquer de l'engrais liquide à partir de bouse de vache en milieu humide., sec ou après production de biogaz, etc..

Obtenez la ligne de fabrication d'engrais liquide au fumier de vache maintenant!

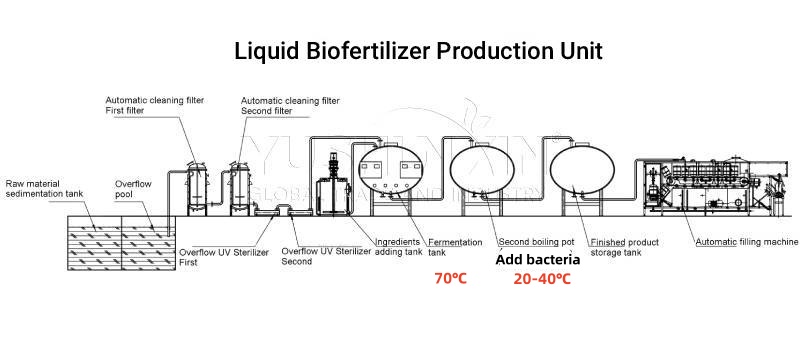

6 Étapes pour fabriquer un engrais liquide à partir de bouse de vache

En général, éliminer la bouse de vache dans un engrais organique liquide de qualité, il a besoin 6 steps.

Récupérez de la bouse de vache fraîche pour la fabrication d'engrais liquide

Généralement, La fabrication d'engrais liquides solubles dans l'eau de qualité commence par la collecte de bouse de vache fraîche. Il est conseillé d’utiliser du fumier frais de bétail. Parce qu'il contient une concentration plus élevée de nutriments et de micro-organismes bénéfiques par rapport aux anciens, fumier séché. En même temps, vous pouvez obtenir le matériel d'engrais liquide directement.

Filtrer la bouse de vache liquide pour la production d'engrais

Il contient 2 parties. Pour une chose, éliminer le fumier de vache solide du liquide. Ici, vous pouvez utiliser un séparateur solide et liquide de fumier. Ou vous pouvez installer une tranchée de sédimentation pour séparer le fumier liquide de vache de manière économique. Pour un autre, filtrer les petites particules du fumier liquide de vache. Donc, vous pouvez produire un engrais soluble dans l’eau qui est plus facile à utiliser. Ici, notre ingénieur adopte une conception de filtrage au charbon actif.

Stérilisation d'engrais liquide UV

Puis afin d’éliminer les agents pathogènes nuisibles, virus, champignons, etc. pour assurer la sécurité des engrais liquides produits. As the name suggests, notre système de fabrication d'engrais liquide à partir de bouse de vache adopte UV sterilization technologie. Son taux d'élimination des agents pathogènes peut atteindre 99%.

Ajout de matériel auxiliaire

Si vous souhaitez ajouter du NPK, oligo-éléments pour améliorer la teneur en éléments nutritifs ou mélasse ou agent de fermentation pour accélérer la fermentation de l'engrais liquide, il y a un réservoir de dosage pour vous. Mélanger des additifs avec de l'eau, le réservoir de dosage sera ensuite envoyé au fermenteur de fumier de vache liquide selon les proportions requises.

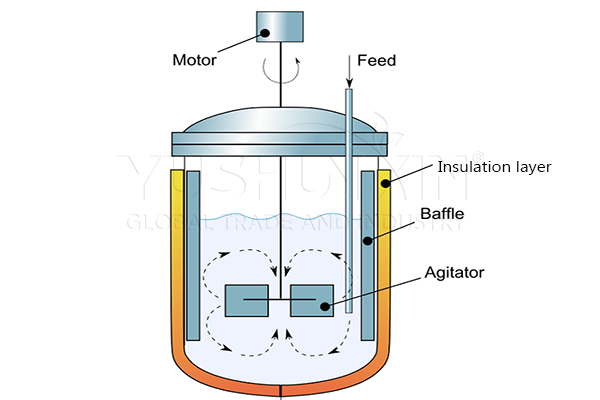

Mélange et fermentation d'engrais liquide avec fumier de vache

Pour produire de l'engrais liquide à partir de bouse de vache, la fermentation est importante. Similaire à la production d’engrais à base de fumier solide de vache, c'est un processus inoffensif d'engrais liquide. Avec mélange de réacteur d'engrais liquide en acier inoxydable, une hydrolyse enzymatique aura lieu pour décomposer les substances nutritives en molécules plus petites et éliminer davantage les agents pathogènes nocifs présents dans les matériaux.

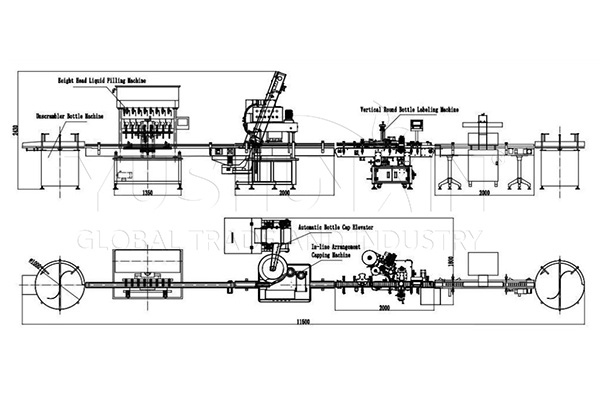

Emballage d'engrais liquide de fumier de vache

Finally, for production commerciale d'engrais liquide, vous devez emballer de l'engrais de fumier de vache fini. Pour ça, la machine de remplissage de liquide automatique est le meilleur choix. Il peut terminer le remplissage d'engrais liquide, covering, étiquetage, etc..

Obtenez votre ligne de fabrication d'engrais liquide au fumier de vache personnalisée!

Combien de temps faut-il pour la fermentation du fumier liquide de vache?

Commonly, le temps de fermentation de l'engrais liquide avec du fumier de vache dépend de la méthode utilisée.

- Pour utilise des enzymes pour décomposer le liquide de lisier de vache, la fermentation anaérobie, it needs only 3-7 jours.

- Quant à la fermentation aérobie avec hydrolyse bactérienne, ça te prend habituellement 15-25 jours.

Therefore, nous vous recommandons généralement d'acheter une cuve de fermentation anaérobie pour fabriquer de l'engrais liquide à partir du fumier de vache.

Combien d'agents chélateurs doivent être ajoutés pendant la fermentation liquide?

Afin de fabriquer rapidement de l'engrais liquide à partir de bouse de vache, vous pouvez également choisir d'ajouter des agents chélateurs pour accélérer la réaction du liquide. Il utilise principalement sa chélation avec des ions métalliques pour former des chélates solubles.. Ce qui peut augmenter la concentration de nutriments inorganiques dans les engrais liquides, et empêcher la cristallisation et la précipitation. Quant à la quantité d'agent chélateur ajoutée, il est généralement inférieur à 5% de la masse de la matière première.

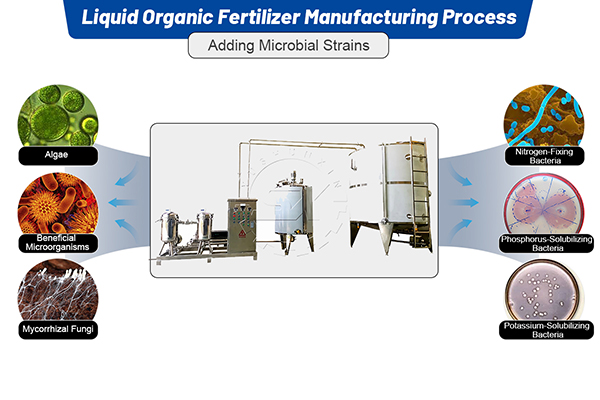

Comment produire de l'engrais bio liquide avec du fumier de vache?

Si vous souhaitez transformer du fumier de vache en biofertilisant liquide, la ligne de fabrication d'engrais ci-dessus peut également répondre pleinement à vos besoins. Il vous suffit d'ajouter un système de chélation secondaire et des composants de membrane d'ultrafiltration après le réacteur d'engrais liquide de fumier de vache..

- Le premier est essentiel pour garantir la survie des micro-organismes dans la fabrication de biofertilisants liquides à base de bouse de vache.. Cela contrôlera la température des bactéries fonctionnelles qui s'ajoutent et se dissolvent à 20-40 ℃, qui empêchent les dommages à haute température.

- Ce dernier consiste à éliminer les minuscules particules, spores fongiques, et résidus insolubles du bioengrais liquide de chélation secondaire. Avec 0.1 m m-0.2précision de filtrage μm, vous pouvez produire un meilleur engrais liquide et réduire le colmatage lors du processus de remplissage de liquide ultérieur.

Obtenez votre ligne de fabrication d'engrais liquide au fumier de vache personnalisée!

Pouvons-nous transformer le fumier sec de vache en engrais liquide?

Of course. Pour transformer le fumier sec de vache en engrais liquide, il est conseillé d'ajouter de l'eau avant la fermentation de l'engrais liquide.

Ici, YUSHUXIN peut vous fournir du matériel d'osmose inverse, qui peut offrir de l'eau de haute pureté pour la fabrication d'engrais liquide au fumier de vache. Il peut purifier l'eau du robinet municipal, eaux souterraines ou eaux de surface et eaux de lac non polluantes. Generally, le processus de production d'engrais liquide de bouse de vache sèche idéal est le broyeur de bouse de vache → équipement d'osmose inverse (ajout d'eau)→ réservoir de stockage → réacteur liquide → filtres solides → équipement de remplissage de liquide

Existe-t-il une usine d'engrais opérationnelle pour fabriquer des engrais liquides à partir de bouse de vache ??

Of course. De nombreux fabricants démarrent leur activité d'engrais liquide avec de la bouse de vache avec l'équipement YUSHUNXIN. For example, le 5 janvier 2025, un client éthiopien a demandé comment éliminer les déchets de fumier de vache en engrais? Tenir compte de la demande du marché local et du retour sur investissement, il a finalement choisi d'acheter un système de fabrication d'engrais liquide pour l'élimination de la bouse de vache éthiopienne. 1000 L/jour. Maintenant, il nous a dit que le système fonctionnait bien et qu'il commençait à vendre les engrais liquides produits aux clients..

Aperçu du projet

- Country: Ethiopie

- Capacité: 1 ème

- Material: bouse de vache

- Exigence: Fabrication d'engrais liquide

- Coût: $75,640 USD

Si vous avez d'autres questions sur la fabrication d'engrais liquide à partir de bouse de vache, bienvenue à nous contacter immédiatement. Of course, YUSHUNXIN peut également vous proposer d'autres lignes de fabrication d'engrais liquides. Tel qu'un système pour fabriquer de l'engrais liquide avec du fumier de poulet, fumier de porc, déchets de biogaz, etc..