Can YUSHUNXIN offer fertilizer dryer replacement parts to make fertilizer making line work for a longer time? Bien sûr. Whether you need main gear, pignon, ou roues à tourillon, anneaux d'équitation, rouleaux de poussée, etc., it is available in YUSHUNXIN fertilizer equipment manufacturer factory. Not only for rotary drying machine, but also used on rotary drum granulator or coating machine. En outre, nous pouvons pleinement répondre à vos exigences de personnalisation sur la taille, matériel, conception unique, etc., en raison de l'équipement de fabrication professionnel.

What kind of fertilizer dryer replacement parts are offered?

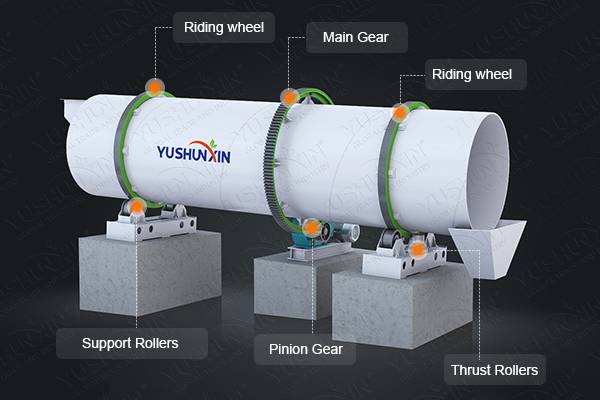

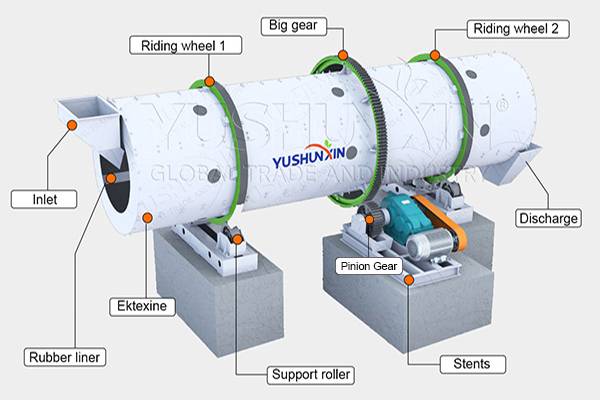

As professional fertilizer equipment supplier, YUSHUNXIN can offer you components for fertilizer dryer of both drive assembly and lubrication assembly. These parts are essential to ensure smooth rotation, correct alignment, and stable transmission.

Drive assembly

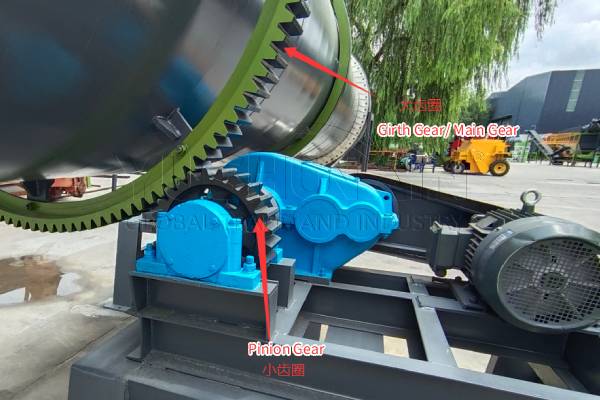

It transmits power from the motor to the rotating drum, ensuring the proper speed and rotation. Key components of the drive assembly include:

- Pinion Gear: The pinion gear meshes with the girth gear to facilitate the rotation of the drum. Over time, these gears can wear down, requiring replacement to ensure smooth operation.

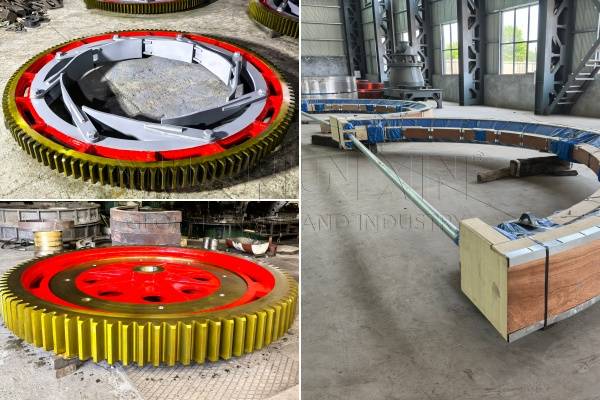

- Main Gear (Girth Gear): This large gear is responsible for transmitting the rotational force from the drive shaft to the drum of the fertilizer dryer. It is a heavy-duty component that requires occasional replacement to avoid breakdowns.

- Coupling: The coupling connects the motor and the drive components, transmitting power efficiently. A malfunctioning coupling can result in inefficient operation or even complete failure of the system.

Lubrication assembly

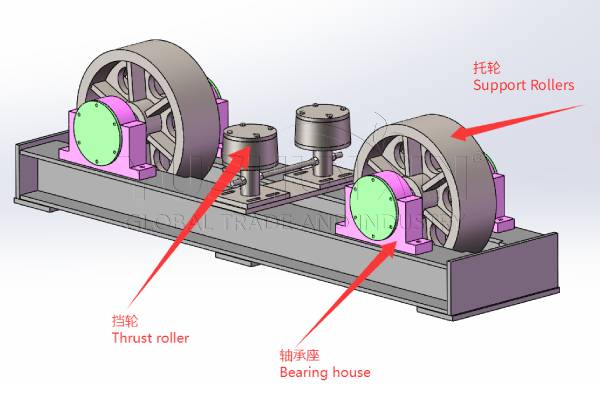

The lubrication assembly is another critical part of the fertilizer dryer. It ensures that all moving parts run smoothly, reducing friction and extending the lifespan of the equipment. Key components of the lubrication assembly include:

- Support Rollers / Trunnion Wheel: These are the main components responsible for supporting the rotating drum of the dryer. They reduce wear and ensure smooth operation.

- Riding wheel / Tyre Rings: Riding rings are essential for the stability and rotation of the dryer drum. These rings support the drum’s weight and prevent friction between the drum and support bearings.

- Thrust Rollers: These components also help in stabilizing the drum, ensuring that the dryer rotates evenly.

Proper lubrication and the replacement of worn-out parts in this assembly can significantly improve dryer efficiency and extend its lifespan.

Can you offer customized components for rotary dryers?

Oui, customized components can be tailored for your rotary dryer. Customization services ensure that the parts are a perfect fit for your specific needs, providing greater efficiency and reliability. Key customization options include:

Size: Fertilizer dryers come in a variety of sizes. Custom parts can be designed for dryers with diameters ranging from 1.2 meters (pour 3-5 TPH dryers) à 2 meters (pour 8-15 TPH dryers), ensuring that all components fit perfectly.

Matériel: The most common material used for dryer components is cast steel, but we also offer customized materials such as cast iron, acier allié, and forged steel. These materials can be tailored to suit different operational requirements.

Conception: Custom components can include split designs or modifications to enhance structural strength, optimizing the durability of your dryer.

By choosing customized parts, you can ensure that your fertilizer dryer operates efficiently and lasts longer, reducing the need for frequent repairs or replacements.

Can these parts be used as rotary granulators and coating machines spare parts?

Oui, many of the parts used in fertilizer dryers are also compatible with rotary rotary drum granulators, drum coating machines and drum Mélangeur d'engrais BB.

These machines share similar components, such as thrust rollers, anneaux d'équitation, and drive assemblies. Donc, the same replacement parts can be used to maintain and repair rotary granulators and coating machines, ensuring the overall efficiency of your fertilizer production line.

Haut 2 machines for manufacturing fertilizer dryer replacement parts

To manufacture high-quality replacement parts for fertilizer dryers, we dopts specialized machinery in factory. Tel que

Vertical Turret Lathe (VTL): This machine is ideal for machining large components such as gears and thrust rollers. The VTL allows for high precision and efficiency when shaping and finishing heavy-duty parts.

Gear Hobbing Machine: This machine is used for cutting precise gears, including pinion gears and girth gears, which are crucial components in the drive assembly of a fertilizer dryer. Gear hobbing ensures that the teeth of the gears are shaped with accuracy, resulting in smoother and quieter operation.

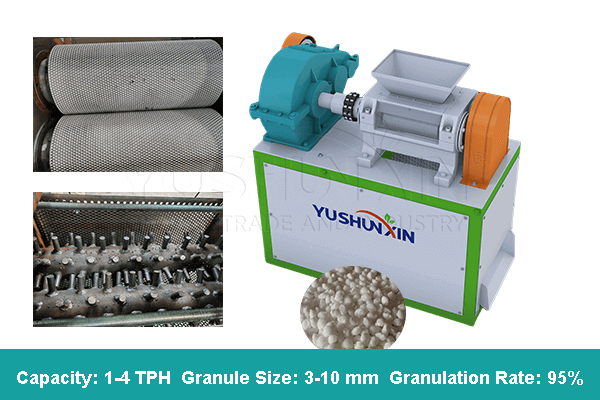

En plus, when you need other replacement parts for your fertilizer making line setup, YUSHUNXIN also can offer the best one. Tel que, roller sheets of granulateur d'extrusion à double rouleau, stirring teeth of new type granulateur d'engrais organique, turning parts of machine à composter, etc..