Lograr uniformidad en la fabricación de gránulos de fertilizantes es crucial para la eficiencia de la aplicación y la distribución de nutrientes.. YUSHUNXIN los ingenieros tienen 5 Consejos prácticos para producir gránulos de fertilizantes de tamaño constante.:

Consejos 1: Aplastante materia prima antes de la granulación de fertilizantes

Comience con materias primas que produzcan fertilizantes de tamaño de partícula uniforme.. Usar trituradora de fertilizante triturar abono o materiales químicos hasta obtener un polvo homogéneo. Dado que los tamaños de partículas inconsistentes en la mezcla inicial pueden dar lugar a tamaños de gránulos variados. La uniformidad en las materias primas ayuda a lograr uniformidad en los gránulos terminados..

Consejos 2: Control de humedad para mejorar los gránulos de fertilizante

Además, el contenido de humedad adecuado también es esencial para una granulación exitosa del fertilizante. Permite que el polvo se una de manera efectiva sin humedecerse ni secarse demasiado.. Los niveles de humedad suelen oscilar entre 10-30%, dependiendo de la tecnología de granulación. El máquina de granulación seca requiere un debajo 10% humedad mientras equipo de granulación húmeda needs a 20%-40% contenido de agua.

Consejos 3: Ajuste regular del equipo de granulación

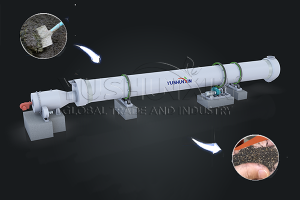

Calibrando tu Equipos para hacer gránulos de fertilizante. regularmente. Si utiliza granuladores de bandeja, peletizadoras de tambor rotativo o máquinas granuladoras por extrusión. Parámetros como el ángulo del disco., espacio entre rodillos, velocidad de rotación y cantidad de solución aglutinante, etc.. Porque, después de un largo período de uso del equipo de granulación de fertilizantes, el equipo puede tener matices. Por lo tanto, debe ajustarlo para garantizar que pueda producir gránulos de fertilizante con un tamaño uniforme..

Obtenga más información sobre la fabricación de gránulos de fertilizante!

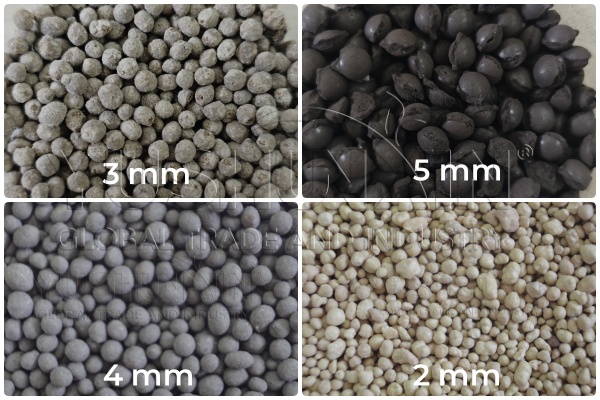

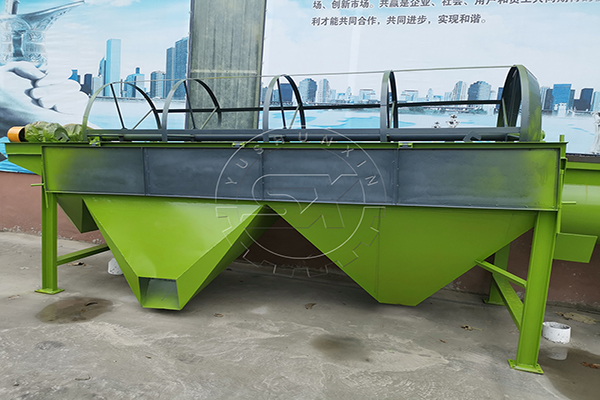

Consejos 4: Tamizar los gránulos de fertilizante del tamaño requerido

Después de la granulación inicial de materiales fertilizantes., usar un criba rotativa o equipo de tamizado similar para separar la materia orgánica o NPK gránulos de fertilizante por tamaño. Los gránulos de tamaño demasiado grande y de tamaño insuficiente se deben separar de los gránulos del tamaño correcto.. Los gránulos fuera de tamaño luego se pueden triturar y reciclar nuevamente al proceso de granulación para reformarlos al tamaño deseado..

para resumir, Lograr una producción uniforme de gránulos de fertilizante implica una combinación de preparación constante de la materia prima., gestión meticulosa de la humedad, Calibración precisa del equipo y cribado riguroso con recirculación eficiente de material fuera de tamaño.. El control y la atención al detalle en cada una de estas áreas darán como resultado la producción de gránulos de fertilizante de tamaño uniforme., mejorar la eficacia y comerciabilidad del producto.