cuando empiezas producción de fertilizantes orgánicos, La ocupación del espacio es un elemento en el que debes centrarte.. Porque juega un papel importante en equipos de fertilizantes organicos elección y diseño de plantas de fertilizantes orgánicos. Entonces, ¿cuánta área de trabajo necesita la producción de fertilizantes orgánicos?? Puedes obtener una respuesta de esta publicación..

Obtenga la ocupación específica del área de su línea de elaboración de fertilizantes orgánicos

¿Cuántas partes contiene un sistema de elaboración de fertilizantes orgánicos??

Antes de estimar el área ocupada por su organic fertilizer production line, será mejor que entiendas cuántas partes contiene. En general, una fábrica de fabricación de fertilizantes orgánicos consta de 4 partes de la siguiente manera:

- Área de materiales: Sólo se utiliza para el almacenamiento temporal de estiércol y materiales auxiliares como paja.. Si no llueve a menudo, Puedes ponerlo en un lugar al aire libre..

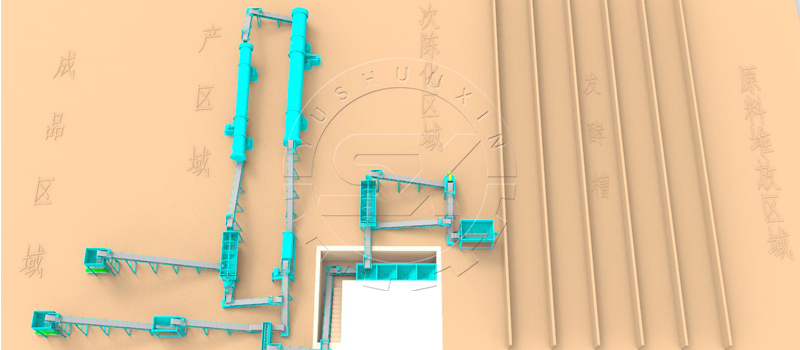

- Área de compostaje: Como su nombre indica, Vas a abono de residuos organicos en esta área. Puedes optar por construir surcos de fermentación o hacer fermentación aeróbica de estiércol directamente sobre este terreno llano. Además, también contiene espacio para el envejecimiento del fertilizante compost..

- Taller de elaboración de abonos orgánicos.: Esta zona está preparada para la instalación de máquinas que puedan convertir el compost en energía o en abono orgánico granulado.. Como trituradora, mezclador, granulador, secadora, etc.. Es recomendable construir un taller con una altura de 6 m para el área. Puede reducir el desgaste de los equipos de fertilizantes orgánicos y prolongar su vida útil..

- Área de productos fertilizantes orgánicos terminados: Este es un lugar de almacenamiento de productos fertilizantes orgánicos terminados..

Cómo montar una planta de fabricación de fertilizantes orgánicos?

¿Cuánto espacio requiere una línea de producción de fertilizantes orgánicos??

Para ser sincero, no esta arreglado. Porque el área de trabajo de un sistema de fabricación de fertilizantes orgánicos se ve afectada por muchos factores. Como la capacidad, número de equipo, forma final del fertilizante, etc.. Hay algunos ejemplos para su referencia..

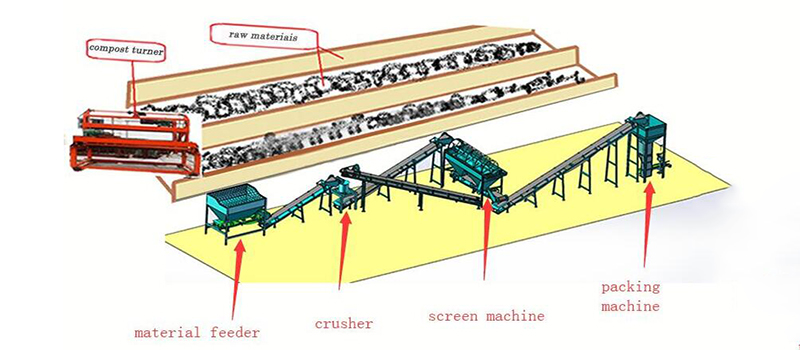

1-5 Línea de fabricación de fertilizantes orgánicos en polvo a pequeña escala t/h

- Configuración: Volteador de abono y abono, máquina de alimentación, trituradora semihúmeda, máquina de cribado, packaging machine, cinta transportadora

- Ocupación del área: 800-1,500 ㎡(acerca de 0.2-0.4 acres)

10-20 t/h sistema de producción de fertilizantes orgánicos en polvo a gran escala

- Configuración: Volteador de abono y abono, máquina de alimentación, pulverizador vertical, máquina de cribado, packaging machine, cinta transportadora

- Ocupación del área: 3,000-5,000 ㎡(acerca de 0.8-1.3 acres)

1-5 Línea de fabricación de fertilizantes orgánicos granulados a pequeña escala t/h

- Configuración: Máquina de compostaje de fertilizantes, máquina dosificadora, trituradora semihúmeda, powder screener, máquina dosificadora, granulador de dientes agitadores, secadora y refrigerador, máquina de cribado de gránulos, máquina de recubrimiento, packaging machine, cinta transportadora

- Ocupación del área: 2,000-4,500 ㎡(acerca de 0.5-1.2 acres)

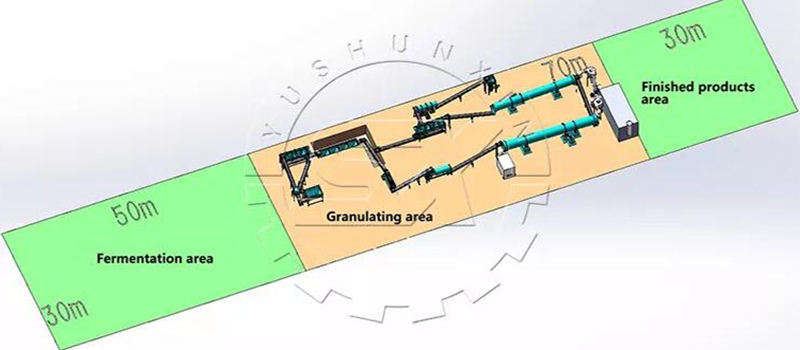

10-20 t/h sistema de preparación de fertilizante orgánico granular a gran escala

- Configuración: Máquina de compostaje de fertilizantes, máquina dosificadora, vertical crusher, powder screener, máquina dosificadora, granulador de tambor rotatorio, secadora and cooler, máquina de cribado de gránulos, máquina de recubrimiento, packaging machine, cinta transportadora

- Ocupación del área: 5,500-10,000 ㎡(acerca de 1.4-2.5 acres)

Los datos anteriores son solo para referencia.. Si desea conocer la ocupación específica del área de su línea de elaboración de fertilizantes orgánicos, Puedes contactar con nosotros directamente siguiendo el formulario de contacto..